Ozric

Active Member

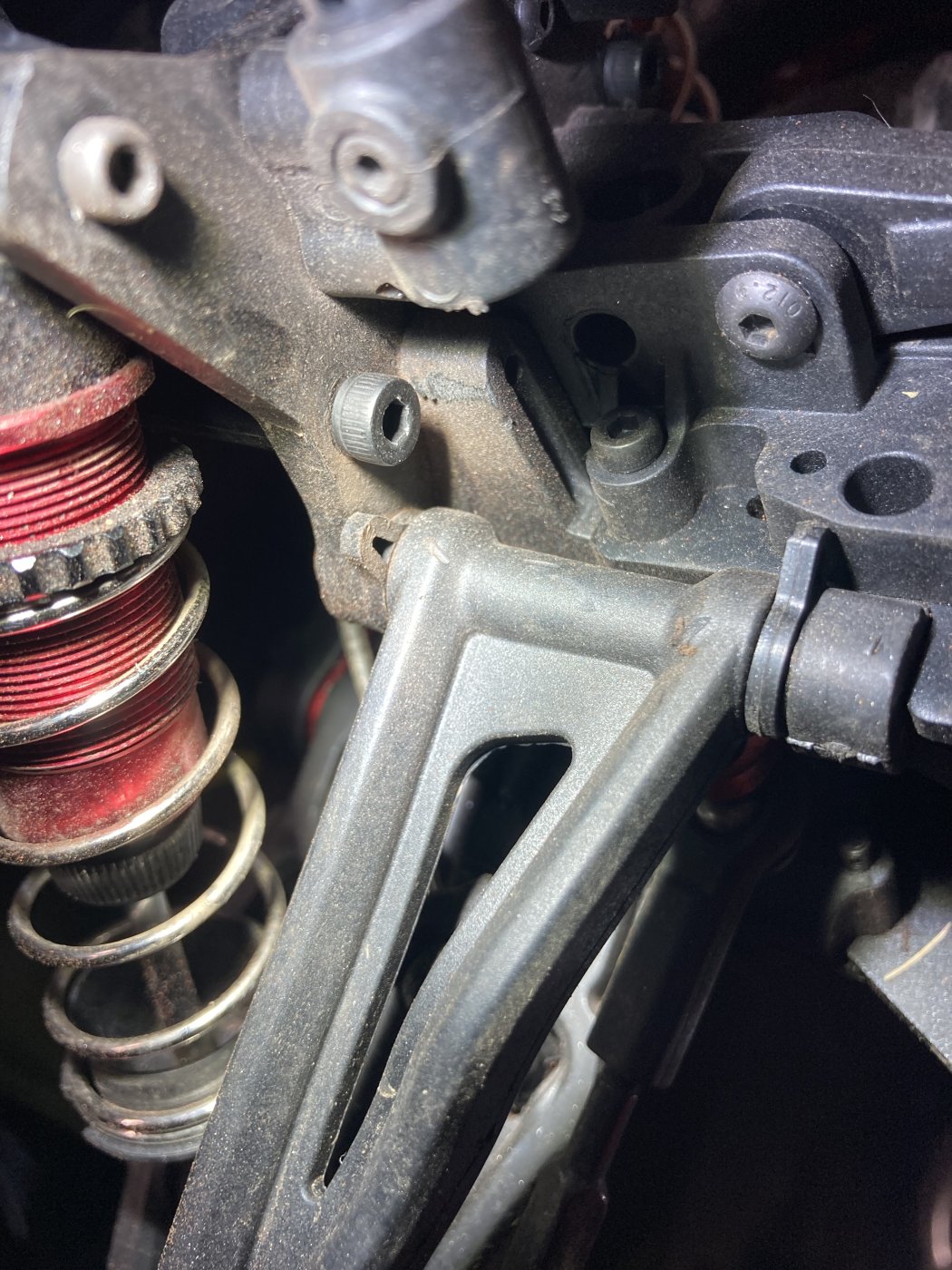

I got sick of stripping the bumper/skid mount screws so I switched to a hardened cap head (3mm driver)

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Cap head/button screws will even strip out when brand new. Especially if you never use heat first to loosen the TL.

Yeah that's a popular thing to do. Especially in that location.

Socket head screws have a deep hex. Cap Head screws are too shallow.

Very important to do with the motor mount meshing screws also. I change to socket head screws out the box when new. These screws use Blue Threadlocker. Cap head/button screws will even strip out when brand new. Especially if you never use heat first to loosen the TL.

These are much deeper that the original for sure.Yeah that's a popular thing to do. Especially in that location.

Socket head screws have a deep hex. Cap Head screws are too shallow.

Very important to do with the motor mount meshing screws also. I change to socket head screws out the box when new. These screws use Blue Threadlocker. Cap head/button screws will even strip out when brand new. Especially if you never use heat first to loosen the TL.

Butane torch. I use a piece of aluminium foil to cover surrounding area that had plastic partsHow do you guys apply heat, in that scenario? I've used a soldering iron tip sometimes. But I also have a small butane torch that I could use, if it was an area that's all-metal, without too much risk of melting nearby items. That seems like maybe a better idea.

Socket head screws are always deeper than Button head screws. Way less chance of stripping out.

Heat gun, solder tip or Torch. All will work. Depending what screws you are are working on.How do you guys apply heat, in that scenario? I've used a soldering iron tip sometimes. But I also have a small butane torch that I could use, if it was an area that's all-metal, without too much risk of melting nearby items. That seems like maybe a better idea.

Register and gain access to Discussions, Reviews, Tech Tips, How to Articles, and much more - on the largest Arrma RC community for RC enthusiasts that covers all aspects of the Arrma-RC brand!

Register Today It's free! This box will disappear once registered!