- Messages

- 10,053

- Reaction score

- 24,677

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

As most of you know I have been attempting to build the ideal body for speedrunning. I thought it would be fun to discuss what an ideal speed run body needs and what it could/should look like.

There are 3 primary focus points for the ideal speed body.

1. Enough downforce to get traction with the 15+ horsepower outputs of the 8s systems. Plus foams need significantly more downforce to find traction.

2. Low drag but also must not flip at high speeds. (so some drag is absolutely necessary to keep the front pinned down)

3. Stiff body that does not flex, which would change the downforce mid-run. (or must be reinforced)

The original example and gold standard was Nic Case's RC bullet which set the RC wheel-driven speed record of 202 mph all those years ago. It is clear to see the front end generates massive downforce! The rear vertical tail has a small silver integrated airfoil for rear downforce. (also aerodynamically hides most of the antenna)

Interestingly enough he had previously tried some more rounded designs that didn't go well like the SR11. It seemed to flip often at 170-180 mph. I should have paid closer attention to that fact when I went on to make bodies rather similar to this that had the same issue.

I'll start by sharing what I have done over the past few years. (does not mean I was right and a few examples were proven to be very wrong)

My first attempt began with a hand-sculpted design for the Unlimited project.

This body design actually is probably the best one I ever have created, now looking back at it with some 20/20 hindsight.

The issue with the Unlimited body was that being hand sculpted it was not 100% symmetrical. The front had one side with a different curvature than the other and I know this would be catastrophic for the car at speeds above 100 mph. I always took my pictures at an angle where it was not very visible

Later I purchased a 3D printer from some of the proceeds of the sale of the Unlimited project. This would allow me to create more accurate molds/plugs for body creation.

The next version was similar but considerably more rounded and smooth. I refer to this as the "Long Nose" 7th scale body.

It generated great frontal downforce. Raz attempted this one many times and had issues with the car fishtailing. It may be worth re-visiting and just needs a rear wing? He was also snapping front axles often, which could have been due to the lack of rear traction? Still a bit of a mystery and could use some more exploring...

Thinking that the long nose body's issue was excessive downforce and looking at designs of well-functioning RC bodies like the 917 and Dome bodies I decided to change the front end significantly while retaining the same mid and rear of the body.

This design proved to not have enough downforce as Raz and another top-name speed runner both confirmed it would flip around 150-160 mph. Now, with that said..... both of them removed the front splitter that was integrated into the body, which removed a significant amount of front downforce. Regardless, it could use more front-downforce and absolutely must have some rear wing to provide rear downforce also. This design I put through some simulations and has extremely low drag, but just not enough downforce as needed for an 8-second blast to insane speeds.

Then a combination of things occurred. James McCoy started testing some new batteries and motors and took the 1/7 scale platform to speeds none of us expected. He did this with the Delta Plastiks 1/7 Ford FC100 body.

This body currently has been 204 mph piloted by James and has some really great design features. Raz and some others have been in the 190-200 mph range with this same body also.

Key features of this body:

1. High downforce front end, but not too much drag.

2. Side channels to control airflow and help alleviate high air pressure zones from washing into low-pressure zones.

3. Built-in rear wing (can be hard to see, but is visible in my plaster copy of the body)

I have a small project going to modify this body because it just works and could be improved slightly.

I never modified the rear, you can see the rear kick-up that acts like a rear wing.

The changes I had made were to smooth out the vents, wheel arches, fake lights, etc. Clearly, I removed a majority of the driver's canopy and streamlined those areas. It cannot be fully removed without making the transition from the hood to harsh.

The other thing I did was remove the rear vertical fins because they would be re-created in a carbon fiber plate after the body is made. They wouldn't mold well and would be impossible to repair a tight internal void in the mold if something went wrong.

I may re-visit finishing the body in the winter when it is not 100 degrees in the garage!!!!

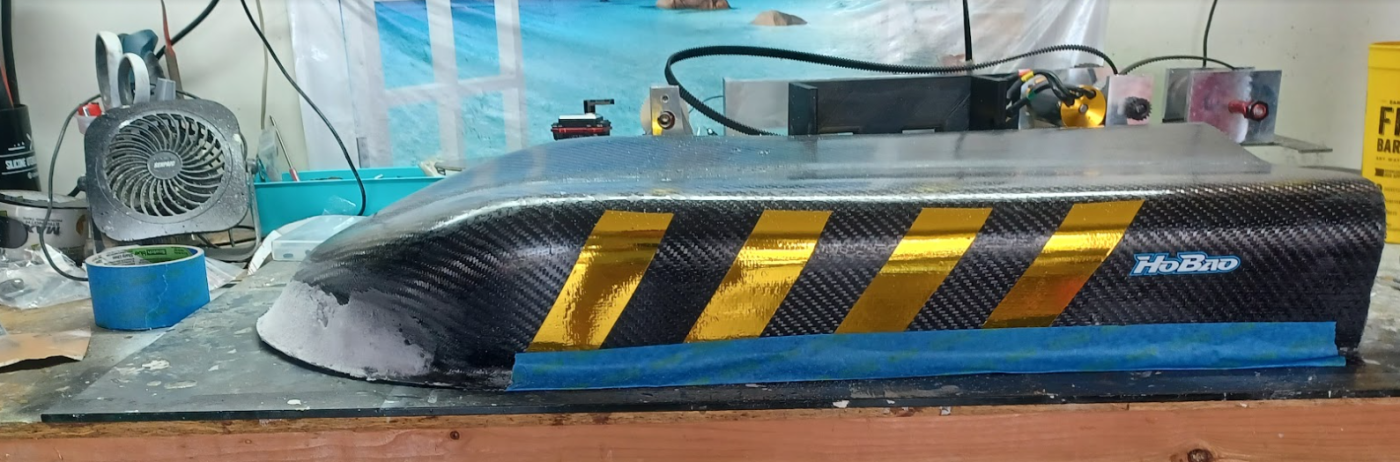

Currently, I am a bit sidetracked working on revising my blunt nose body so that I can utilize it on my 1/7 scale Hobao VTE2 project car. I was chatting with James McCoy about the front and he agreed I need to fix the nose to increase downforce. I wanted to take advantage of the 2 I have in the garage so I have begun modifying the nose and will be ultimately wrapping it with Vinyl so it won't be visible what was done underneath anyway.

I am borrowing some design ideas from the FC100 with some front air guides that will run along the top of the body. These force the air to stay in that area retaining some high pressure downforce creation there over the nose.

I started re-shaping the nose with some loctite expanding foam. I use painters tape to help control where it goes and it won't stick to the blue painter's tape

Now I have applied some body filler over this so I can sand it smoothly to transition into the carbon body without a seam. Then I'll wrap it up with Vinyl that is bright for visibility....

I believe this mod along with a wing will get this body performing the way it needs to be!!!! (fingers crossed)

All of this also has me thinking that my 200+ project body needs more front-end downforce also, which I will need to modify. Currently, I am thinking about some small wings that would extend out of the front of the body to aid in front downforce generation. (mostly because I love the shape and don't want to hack it up too much)

I have been hyperfocus on aerodynamic drag and didn't give enough attention to downforce generation, but enough about my failed attempts LOL

What are your thoughts and what have you tried or thought about trying? Open to hearing your thoughts on what I could do to improve these designs I have or talk about your body and what could be done to help it out.

There are 3 primary focus points for the ideal speed body.

1. Enough downforce to get traction with the 15+ horsepower outputs of the 8s systems. Plus foams need significantly more downforce to find traction.

2. Low drag but also must not flip at high speeds. (so some drag is absolutely necessary to keep the front pinned down)

3. Stiff body that does not flex, which would change the downforce mid-run. (or must be reinforced)

The original example and gold standard was Nic Case's RC bullet which set the RC wheel-driven speed record of 202 mph all those years ago. It is clear to see the front end generates massive downforce! The rear vertical tail has a small silver integrated airfoil for rear downforce. (also aerodynamically hides most of the antenna)

Interestingly enough he had previously tried some more rounded designs that didn't go well like the SR11. It seemed to flip often at 170-180 mph. I should have paid closer attention to that fact when I went on to make bodies rather similar to this that had the same issue.

I'll start by sharing what I have done over the past few years. (does not mean I was right and a few examples were proven to be very wrong)

My first attempt began with a hand-sculpted design for the Unlimited project.

This body design actually is probably the best one I ever have created, now looking back at it with some 20/20 hindsight.

The issue with the Unlimited body was that being hand sculpted it was not 100% symmetrical. The front had one side with a different curvature than the other and I know this would be catastrophic for the car at speeds above 100 mph. I always took my pictures at an angle where it was not very visible

Later I purchased a 3D printer from some of the proceeds of the sale of the Unlimited project. This would allow me to create more accurate molds/plugs for body creation.

The next version was similar but considerably more rounded and smooth. I refer to this as the "Long Nose" 7th scale body.

It generated great frontal downforce. Raz attempted this one many times and had issues with the car fishtailing. It may be worth re-visiting and just needs a rear wing? He was also snapping front axles often, which could have been due to the lack of rear traction? Still a bit of a mystery and could use some more exploring...

Thinking that the long nose body's issue was excessive downforce and looking at designs of well-functioning RC bodies like the 917 and Dome bodies I decided to change the front end significantly while retaining the same mid and rear of the body.

This design proved to not have enough downforce as Raz and another top-name speed runner both confirmed it would flip around 150-160 mph. Now, with that said..... both of them removed the front splitter that was integrated into the body, which removed a significant amount of front downforce. Regardless, it could use more front-downforce and absolutely must have some rear wing to provide rear downforce also. This design I put through some simulations and has extremely low drag, but just not enough downforce as needed for an 8-second blast to insane speeds.

Then a combination of things occurred. James McCoy started testing some new batteries and motors and took the 1/7 scale platform to speeds none of us expected. He did this with the Delta Plastiks 1/7 Ford FC100 body.

This body currently has been 204 mph piloted by James and has some really great design features. Raz and some others have been in the 190-200 mph range with this same body also.

Key features of this body:

1. High downforce front end, but not too much drag.

2. Side channels to control airflow and help alleviate high air pressure zones from washing into low-pressure zones.

3. Built-in rear wing (can be hard to see, but is visible in my plaster copy of the body)

I have a small project going to modify this body because it just works and could be improved slightly.

I never modified the rear, you can see the rear kick-up that acts like a rear wing.

The changes I had made were to smooth out the vents, wheel arches, fake lights, etc. Clearly, I removed a majority of the driver's canopy and streamlined those areas. It cannot be fully removed without making the transition from the hood to harsh.

The other thing I did was remove the rear vertical fins because they would be re-created in a carbon fiber plate after the body is made. They wouldn't mold well and would be impossible to repair a tight internal void in the mold if something went wrong.

I may re-visit finishing the body in the winter when it is not 100 degrees in the garage!!!!

Currently, I am a bit sidetracked working on revising my blunt nose body so that I can utilize it on my 1/7 scale Hobao VTE2 project car. I was chatting with James McCoy about the front and he agreed I need to fix the nose to increase downforce. I wanted to take advantage of the 2 I have in the garage so I have begun modifying the nose and will be ultimately wrapping it with Vinyl so it won't be visible what was done underneath anyway.

I am borrowing some design ideas from the FC100 with some front air guides that will run along the top of the body. These force the air to stay in that area retaining some high pressure downforce creation there over the nose.

I started re-shaping the nose with some loctite expanding foam. I use painters tape to help control where it goes and it won't stick to the blue painter's tape

Now I have applied some body filler over this so I can sand it smoothly to transition into the carbon body without a seam. Then I'll wrap it up with Vinyl that is bright for visibility....

I believe this mod along with a wing will get this body performing the way it needs to be!!!! (fingers crossed)

All of this also has me thinking that my 200+ project body needs more front-end downforce also, which I will need to modify. Currently, I am thinking about some small wings that would extend out of the front of the body to aid in front downforce generation. (mostly because I love the shape and don't want to hack it up too much)

I have been hyperfocus on aerodynamic drag and didn't give enough attention to downforce generation, but enough about my failed attempts LOL

What are your thoughts and what have you tried or thought about trying? Open to hearing your thoughts on what I could do to improve these designs I have or talk about your body and what could be done to help it out.

Last edited: