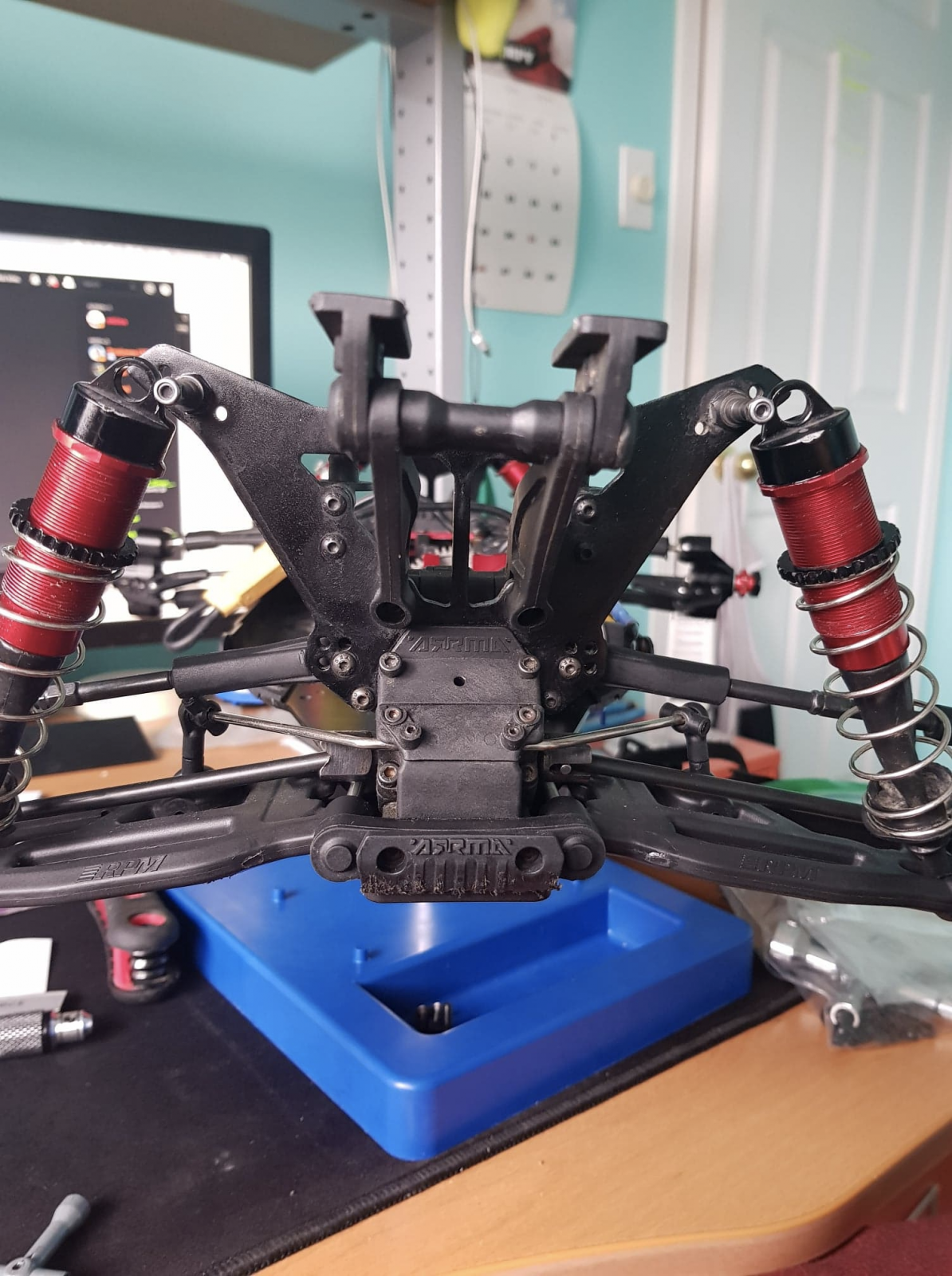

And while fixing the broken rod end, multiple upgrades and changes were done to the car.

In this post, I will go over the upgrades and changes I have done to the car for those interested. Additionally, I will include any notes about specific parts and why I ordered them .

TL;DR: I wanted to fix 1 part to get my kraton running. I proceeded to upgrade multiple things.. money goes weeeee, so does my car. Leave suggestions for ride height for jumping in comments.

The pictures will not be the best because I do not have a workspace for the car, so I just use my desk.

Well, we begin with the thing I actually needed to fix.

Shock Part Set composite [AR330203 ] : Stock V3 rod ends as that is what my LHS had. We will see how they hold up. They were an absolute pain to get on , and I really recommend a shock tool/pliers in order to make things easier..

Fast Eddy Sealed Bearing Kit-ARA Kraton BLX '16 : I wanted to get the bearings anyway, figured now was a good time as ever to do so. They have higher quality than stock, and they are super good.

RCScrewz Keaton Screw kit : I was on the fence about this one, but in the end, I figured that having this is better than not having it if some screws get loose. Normally, I think the recommendation is the Jenny RC Kit, but everything was sold out, so I got what I could. I will report on the screws at a later time.

Hot Racing F/F Suspension Mount [ HRAAON08FF01 ] : A while back, I installed the RPM front bumper, and while it is excellent the front hinge pins came out of it, and so I searched for ways to fix it. The HR F/F arm mount looks awesome and fulfills my purpose of holding the hinge pins in. I know a few people on the forums liked, so I decided to try it. The small form factor should mean that the RPM bumper should not snap anything, unlike putting the stock holder back,

Well.. I am already upgrading and on the site.. might as well look around….

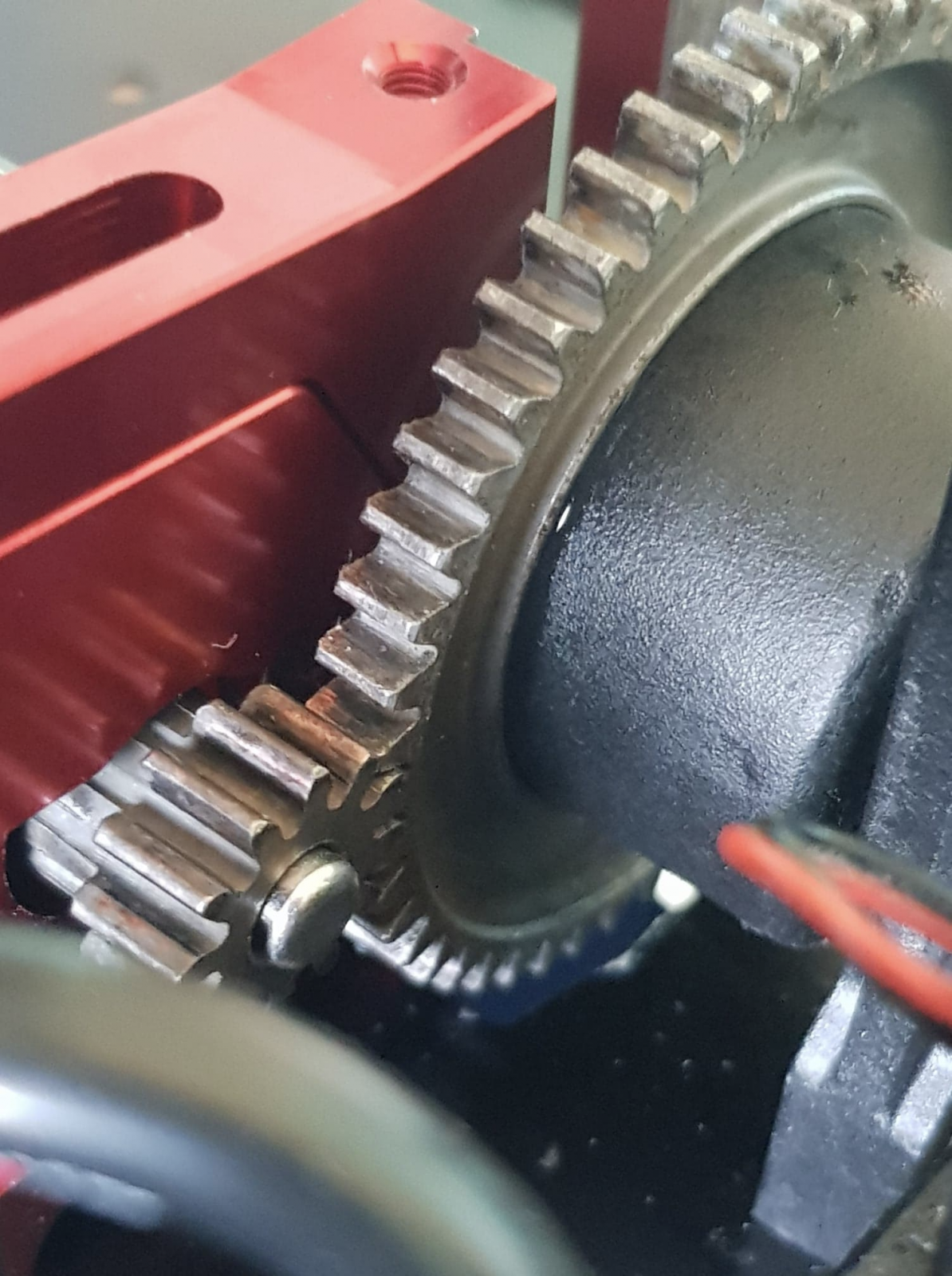

Sliding Centre Differential [ARA320499(diff mount),ARA320468(sliding motor mount)+ARA320469(motor mount plate),ARA727412(screws)]: Ever since the V4 Kratons were announced, I knew I wanted this sliding motor mount. Making Diff and Motor maintenance easier was something I was looking forward to. I mounted it all up and I was very impressed how well everything went together. Performed the paper mesh trick and screwed everything down. Now, one thing to keep in mind is that while it is marketed as making everything easier, that is only half true in a sense. Consider that the sliding plate is metal to metal and still needs to be locitite each time, and you still need to redo the mesh , and it is almost the same amount of work as the v3, albeit less work, so I would say I am happy with it, but it is not as necessary as I thought.

Well.. I have too remove the differential and clean everything anyway.. might as well get some service fluids.

Shock oil ( 1000 CST) : standard, nothing to say about it .

Centre Differential ( 500k) : Been happy with it and see no reason to change the weight. Cleaned + serviced diff, replaced fluid.

F/R Differentials : (10K): Been running on this setup and have been happy. No reason to change it.

Taking a look at the car and I realized that the reason that the rod end may have broken is the delrin piece was gone from the right steering block . Posted about this on Discord and apparently this is a “common thing” (that the delrin seals unscrews) WHAT ???!??!? NO. [Looking back at it, this was literally just an excuse to get what I wanted for a while..]

Hot Racing Kraton Aluminum Steering Block [HRAAON21M01] : No I did not need this, and if I did not impulse buy it after getting upset at the stock delrin caps being removed ( you should really check on them anyway) I would have been fine. I wanted them, they look cool, and the reviews are amazing on them. One racer I know said that i would break more stuff cause they are aluminum and that plastic block would mean flex in all the right places ( insert praise for ARRMA being good with their engineering here). We will see. I have the highest expectations for these.

Fast forward a few days, car is about to be put back fully, I am just placing back the shocks after servicing them. I remembered that the droop is set with the shocks not fastened fully, so I look and what do I see? Nothing.. I have apparently been running without droop screws on the front for a while.. either I forgot them last rebuild, or they fell…

Double Socket Button Head 4x10mm [ARAC9870] : Watched a video and I saw these being recommended, and they are truly awesome.. I highly recommend, made setting the droop super easy, with double sided adjustments. Here is my droop setting for those wondering.

One challenge is that in order to place an order.. I had to purchase >10$CAD.. these things were 8.99.. so …

RPM Rear Skid Plate [RPM81442] : At this point.. everything else I wanted was either out of stock or I want to wait for it. This seemed fine.

Well.. there you have it.. it started with a rod end.. and it ended up with all this. probably not too too outrageous but someone on discord wanted a list of things I did with it, so figured I would post anyway..

Some notes about re-building RC cars I think would be helpful .

1. You need the right tool for the job. In cleaning my centre diff, the damn thing was so dirty that the old fluid got into the teeth of the gear. nothing I had in the house worked. Simple Green, Goo Gone, bike chain degreaser.. The only thing that “worked” was air compressor and let me tell you how annoying that was… Next day, went to my local hardware, picked up some auto cleaner, and what I struggled with for hours was solved in 5 mins…

2. Needle Nose Pliers : I didn’t have them, I got them.. they made everything that was painful before not painful anymore.

3. Shock tool: just.. get it .. it will make your life easier if you are rebuilding the shocks.. Still do not have one, but at this point, I don’t need one until my next order.

4. Digital Caliber : You could measure stuff, but to be honest.. they are inexpensive and save you a ton of time. Find part number, look at measurements, compare to what you have.. done.

What’s next ?

At this point, I will be doing a few upgrades for sure, and everything else will be on a “it broke” basis, and depending on the item, probably will go stock.

Futaba T4PM : No this isn’t for the kraton.. this is mainly for the racing I will be doing at my local track , but I might shove a receiver in the kraton. The Stock TTX300 is really nice and significantly more rugged / easy to replace.. might just keep that.

Pro-Line Backflips/ Badlands : these are an upgrade to the stock, but from the reviews, they are more for dirt and stuff. Due to the restrictions, I am basically able to take the car on grass / gravel and concrete ( almost no jumps) , so no need to ruin good tires right now..

I am currently looking to optimize my ride height for jumps, so if anyone has any suggestions,please leave them in the comments.

Well.. I hope you enjoyed reading this and I do hope that you yourself will re-build your kraton after just needing to fix 1 part.. impulse buying upgrades is good.. tell yourself that every night..

In this post, I will go over the upgrades and changes I have done to the car for those interested. Additionally, I will include any notes about specific parts and why I ordered them .

TL;DR: I wanted to fix 1 part to get my kraton running. I proceeded to upgrade multiple things.. money goes weeeee, so does my car. Leave suggestions for ride height for jumping in comments.

The pictures will not be the best because I do not have a workspace for the car, so I just use my desk.

Well, we begin with the thing I actually needed to fix.

Shock Part Set composite [AR330203 ] : Stock V3 rod ends as that is what my LHS had. We will see how they hold up. They were an absolute pain to get on , and I really recommend a shock tool/pliers in order to make things easier..

Fast Eddy Sealed Bearing Kit-ARA Kraton BLX '16 : I wanted to get the bearings anyway, figured now was a good time as ever to do so. They have higher quality than stock, and they are super good.

RCScrewz Keaton Screw kit : I was on the fence about this one, but in the end, I figured that having this is better than not having it if some screws get loose. Normally, I think the recommendation is the Jenny RC Kit, but everything was sold out, so I got what I could. I will report on the screws at a later time.

Hot Racing F/F Suspension Mount [ HRAAON08FF01 ] : A while back, I installed the RPM front bumper, and while it is excellent the front hinge pins came out of it, and so I searched for ways to fix it. The HR F/F arm mount looks awesome and fulfills my purpose of holding the hinge pins in. I know a few people on the forums liked, so I decided to try it. The small form factor should mean that the RPM bumper should not snap anything, unlike putting the stock holder back,

Before | After |

Well.. I am already upgrading and on the site.. might as well look around….

Sliding Centre Differential [ARA320499(diff mount),ARA320468(sliding motor mount)+ARA320469(motor mount plate),ARA727412(screws)]: Ever since the V4 Kratons were announced, I knew I wanted this sliding motor mount. Making Diff and Motor maintenance easier was something I was looking forward to. I mounted it all up and I was very impressed how well everything went together. Performed the paper mesh trick and screwed everything down. Now, one thing to keep in mind is that while it is marketed as making everything easier, that is only half true in a sense. Consider that the sliding plate is metal to metal and still needs to be locitite each time, and you still need to redo the mesh , and it is almost the same amount of work as the v3, albeit less work, so I would say I am happy with it, but it is not as necessary as I thought.

Well.. I have too remove the differential and clean everything anyway.. might as well get some service fluids.

Shock oil ( 1000 CST) : standard, nothing to say about it .

Centre Differential ( 500k) : Been happy with it and see no reason to change the weight. Cleaned + serviced diff, replaced fluid.

F/R Differentials : (10K): Been running on this setup and have been happy. No reason to change it.

Taking a look at the car and I realized that the reason that the rod end may have broken is the delrin piece was gone from the right steering block . Posted about this on Discord and apparently this is a “common thing” (that the delrin seals unscrews) WHAT ???!??!? NO. [Looking back at it, this was literally just an excuse to get what I wanted for a while..]

Hot Racing Kraton Aluminum Steering Block [HRAAON21M01] : No I did not need this, and if I did not impulse buy it after getting upset at the stock delrin caps being removed ( you should really check on them anyway) I would have been fine. I wanted them, they look cool, and the reviews are amazing on them. One racer I know said that i would break more stuff cause they are aluminum and that plastic block would mean flex in all the right places ( insert praise for ARRMA being good with their engineering here). We will see. I have the highest expectations for these.

Fast forward a few days, car is about to be put back fully, I am just placing back the shocks after servicing them. I remembered that the droop is set with the shocks not fastened fully, so I look and what do I see? Nothing.. I have apparently been running without droop screws on the front for a while.. either I forgot them last rebuild, or they fell…

Double Socket Button Head 4x10mm [ARAC9870] : Watched a video and I saw these being recommended, and they are truly awesome.. I highly recommend, made setting the droop super easy, with double sided adjustments. Here is my droop setting for those wondering.

One challenge is that in order to place an order.. I had to purchase >10$CAD.. these things were 8.99.. so …

RPM Rear Skid Plate [RPM81442] : At this point.. everything else I wanted was either out of stock or I want to wait for it. This seemed fine.

Well.. there you have it.. it started with a rod end.. and it ended up with all this. probably not too too outrageous but someone on discord wanted a list of things I did with it, so figured I would post anyway..

Some notes about re-building RC cars I think would be helpful .

1. You need the right tool for the job. In cleaning my centre diff, the damn thing was so dirty that the old fluid got into the teeth of the gear. nothing I had in the house worked. Simple Green, Goo Gone, bike chain degreaser.. The only thing that “worked” was air compressor and let me tell you how annoying that was… Next day, went to my local hardware, picked up some auto cleaner, and what I struggled with for hours was solved in 5 mins…

2. Needle Nose Pliers : I didn’t have them, I got them.. they made everything that was painful before not painful anymore.

3. Shock tool: just.. get it .. it will make your life easier if you are rebuilding the shocks.. Still do not have one, but at this point, I don’t need one until my next order.

4. Digital Caliber : You could measure stuff, but to be honest.. they are inexpensive and save you a ton of time. Find part number, look at measurements, compare to what you have.. done.

What’s next ?

At this point, I will be doing a few upgrades for sure, and everything else will be on a “it broke” basis, and depending on the item, probably will go stock.

Futaba T4PM : No this isn’t for the kraton.. this is mainly for the racing I will be doing at my local track , but I might shove a receiver in the kraton. The Stock TTX300 is really nice and significantly more rugged / easy to replace.. might just keep that.

Pro-Line Backflips/ Badlands : these are an upgrade to the stock, but from the reviews, they are more for dirt and stuff. Due to the restrictions, I am basically able to take the car on grass / gravel and concrete ( almost no jumps) , so no need to ruin good tires right now..

I am currently looking to optimize my ride height for jumps, so if anyone has any suggestions,please leave them in the comments.

Well.. I hope you enjoyed reading this and I do hope that you yourself will re-build your kraton after just needing to fix 1 part.. impulse buying upgrades is good.. tell yourself that every night..