This is my first Arrma RC and my first build log. No big modifications so far, more of a pre-bash bulletproofing to ensure I don’t break anything straight away.

Unboxing…wow, this thing is a beast!

2 x SMC True Spec DV 11.1V 3s 5200mAh 75C hardcase LiPo batteries.

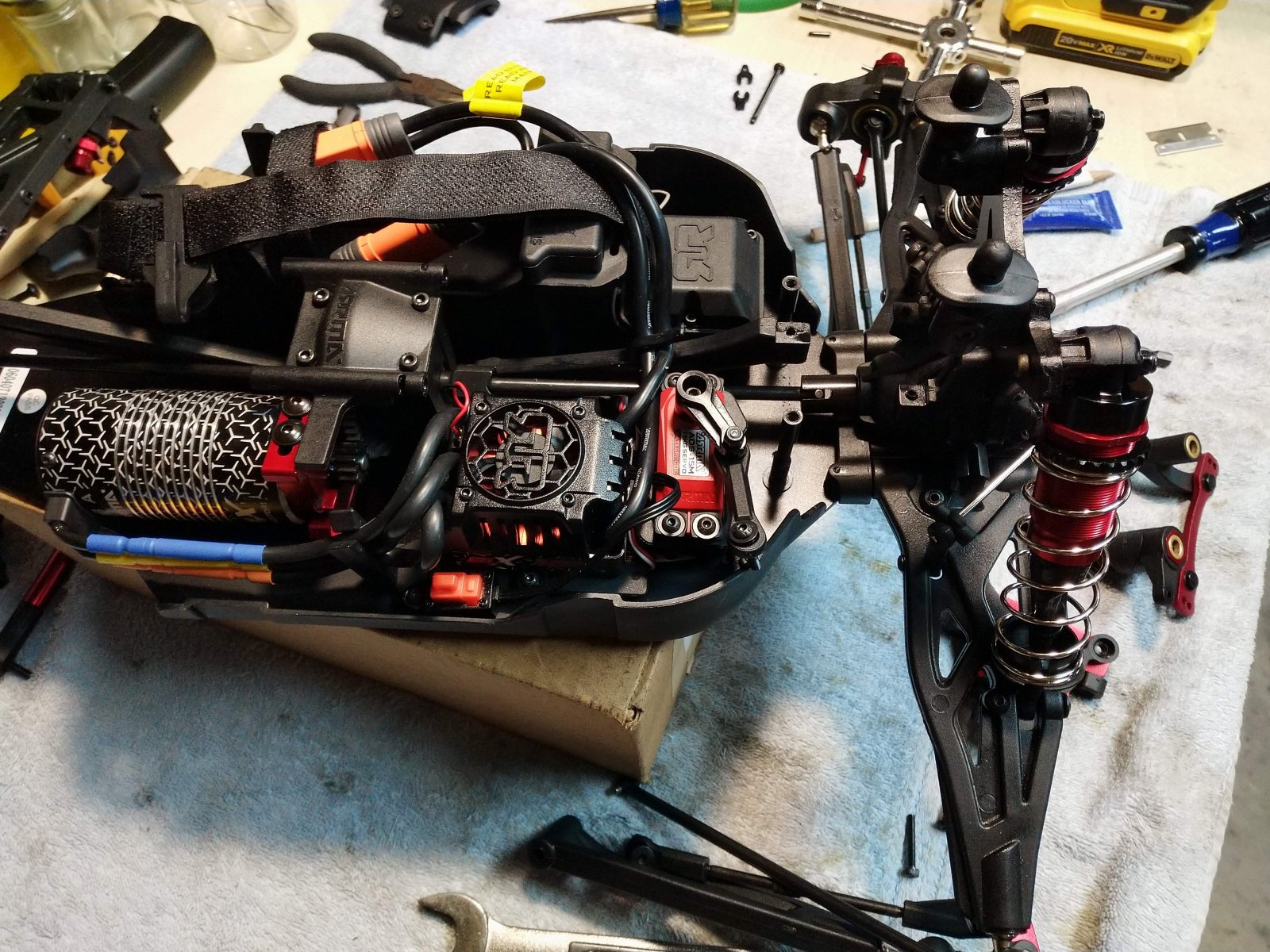

Overall picture with all pre-bash items to be installed.

Applied drywall tape and ShoeGoo to the underside of the shell to strengthen the body and extend its life.

Replaced stock bearings with AVID RC sealed bearing kit throughout vehicle.

Fabricated longer wheel hub hex shafts from old allen keys, then slotted the wheels using an oscillating tool. This keeps the hexes from spinning within the wheels.

Tightened servo saver by placing two 9/16” snap rings under the spring.

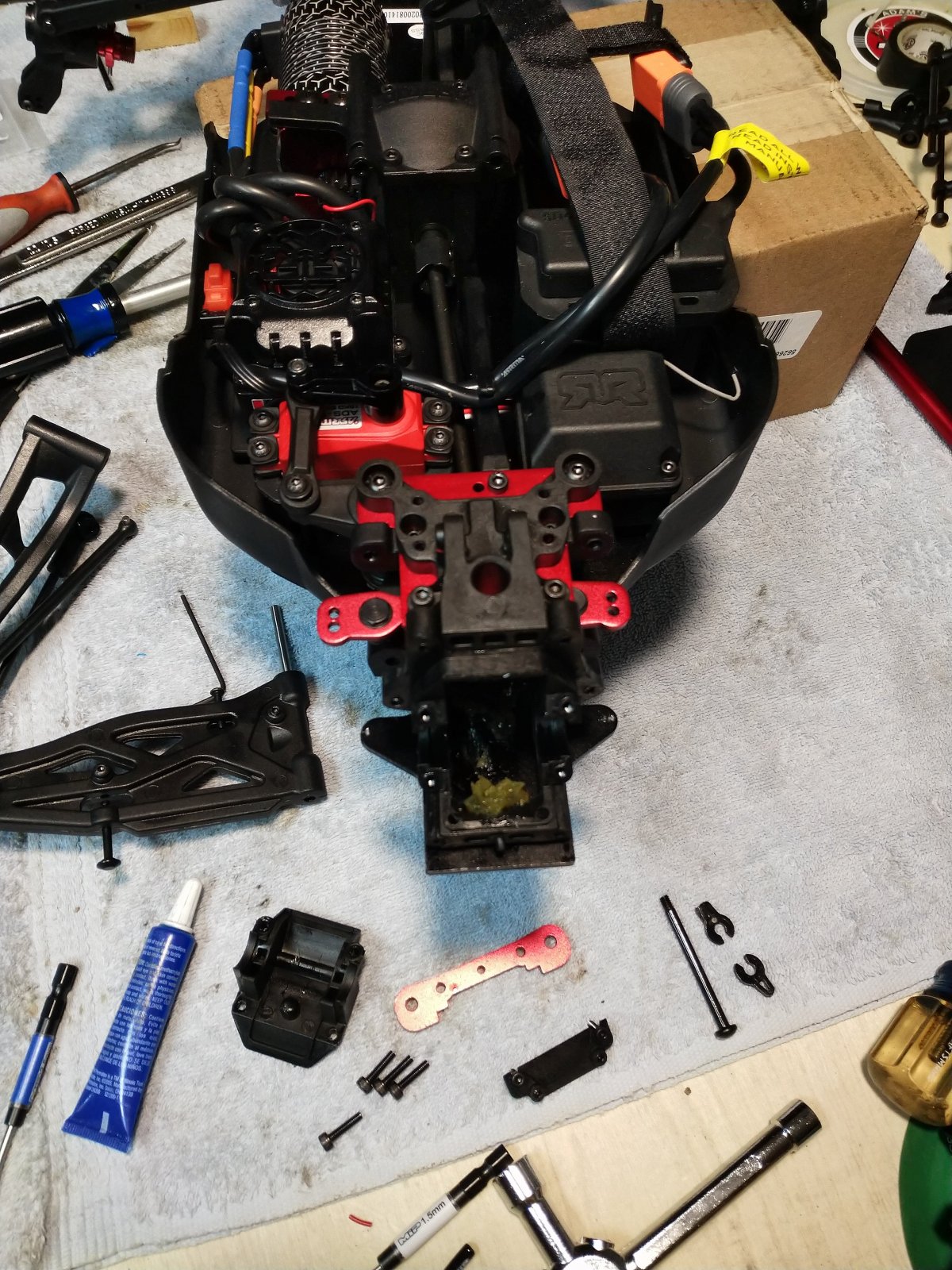

Ooof! Hasn’t been run yet and I’ve already pulled it apart…hope it goes back together again.

Disassembled all three differentials changing fluids (60k front / 300k center / 30k rear), adding Mugen Seiki E0206 shims to the internals (1 large shim behind each planetary gear, 1 small shim behind each of the satellite gears (front & rear diff), and 1 small shim behind one satellite gear on each side (center diff)), and adding TEKNO RC TKR1222 13x16x.1mm shims (2 front / 3 rear) between the bearing and the diff housing. All three differentials were low on fluid, especially the center diff that barely had anything inside. Regreased front and rear differential pinion and main gears with red general purpose grease.

To prevent ballooning of the tires, vented each tire in 4 locations (at 0°/90°/180°/270°) using 1/8” brass tubing sharpened with an exacto knife, covered the holes inside the wheels with Gorilla tape, then strapped the tires using black heavy weight braided fishing line threaded through the lugs using a large needle and pliers. I followed this video to strap the tires

.

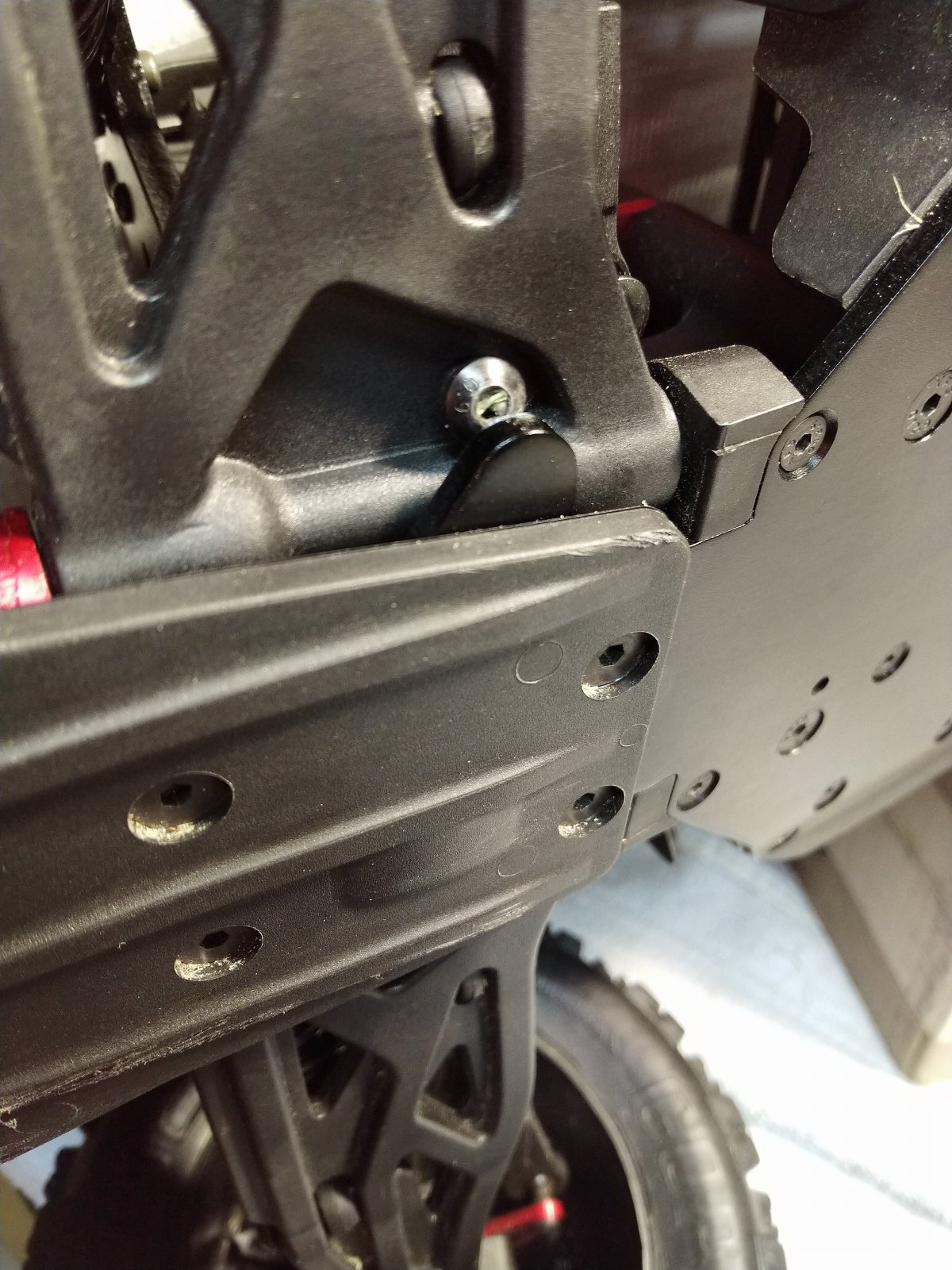

Replaced stock droop screws with Arrma 4x10mm button head screws, ARA727410. These have allen heads on both the button head and inside the screw shaft to allow for tightening. Benefit is a larger contact point with the chassis, resulting is less damage to the chassis. Correctly adjusting the droop relieves pressure from the lower shock mounts and should result in less breakage of that part.

Installed RPM front bumpers on both front and rear, RPM81472, along with Arrma wheelie bar, ARA320366.

Installed Surpass Hobby 30mm Rocket motor fan and heat sink. Routed wire under the ESC and plugged into the 3rd channel of the receiver.

Drilled through motor wire holder and installed zip tie to hold wires in place.

Installed LiPo low-voltage cutout alarm to the center body support bracket.

Checked tightness of all screws.

Took it for a bash. This thing is a monster! Only complaints are the stock STX2 radio transmitter lag (working with Horizon Hobby for a replacement, otherwise will upgrade) and the amount of grass and dirt that accumulated around the rear driveshafts and inside the chassis (plan to fabricate some guards using .060” lexan sheet).

All-in-all I feel the pre-bash work was well worth the effort. I’ll post updates as further modifications / upgrades are made.

Unboxing…wow, this thing is a beast!

2 x SMC True Spec DV 11.1V 3s 5200mAh 75C hardcase LiPo batteries.

Overall picture with all pre-bash items to be installed.

Applied drywall tape and ShoeGoo to the underside of the shell to strengthen the body and extend its life.

Replaced stock bearings with AVID RC sealed bearing kit throughout vehicle.

Fabricated longer wheel hub hex shafts from old allen keys, then slotted the wheels using an oscillating tool. This keeps the hexes from spinning within the wheels.

Tightened servo saver by placing two 9/16” snap rings under the spring.

Ooof! Hasn’t been run yet and I’ve already pulled it apart…hope it goes back together again.

Disassembled all three differentials changing fluids (60k front / 300k center / 30k rear), adding Mugen Seiki E0206 shims to the internals (1 large shim behind each planetary gear, 1 small shim behind each of the satellite gears (front & rear diff), and 1 small shim behind one satellite gear on each side (center diff)), and adding TEKNO RC TKR1222 13x16x.1mm shims (2 front / 3 rear) between the bearing and the diff housing. All three differentials were low on fluid, especially the center diff that barely had anything inside. Regreased front and rear differential pinion and main gears with red general purpose grease.

To prevent ballooning of the tires, vented each tire in 4 locations (at 0°/90°/180°/270°) using 1/8” brass tubing sharpened with an exacto knife, covered the holes inside the wheels with Gorilla tape, then strapped the tires using black heavy weight braided fishing line threaded through the lugs using a large needle and pliers. I followed this video to strap the tires

Replaced stock droop screws with Arrma 4x10mm button head screws, ARA727410. These have allen heads on both the button head and inside the screw shaft to allow for tightening. Benefit is a larger contact point with the chassis, resulting is less damage to the chassis. Correctly adjusting the droop relieves pressure from the lower shock mounts and should result in less breakage of that part.

Installed RPM front bumpers on both front and rear, RPM81472, along with Arrma wheelie bar, ARA320366.

Installed Surpass Hobby 30mm Rocket motor fan and heat sink. Routed wire under the ESC and plugged into the 3rd channel of the receiver.

Drilled through motor wire holder and installed zip tie to hold wires in place.

Installed LiPo low-voltage cutout alarm to the center body support bracket.

Checked tightness of all screws.

Took it for a bash. This thing is a monster! Only complaints are the stock STX2 radio transmitter lag (working with Horizon Hobby for a replacement, otherwise will upgrade) and the amount of grass and dirt that accumulated around the rear driveshafts and inside the chassis (plan to fabricate some guards using .060” lexan sheet).

All-in-all I feel the pre-bash work was well worth the effort. I’ll post updates as further modifications / upgrades are made.

Last edited: