jkflow

TB RC Bashers

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

OSE - highly recommended for anything boat and other general stuff.

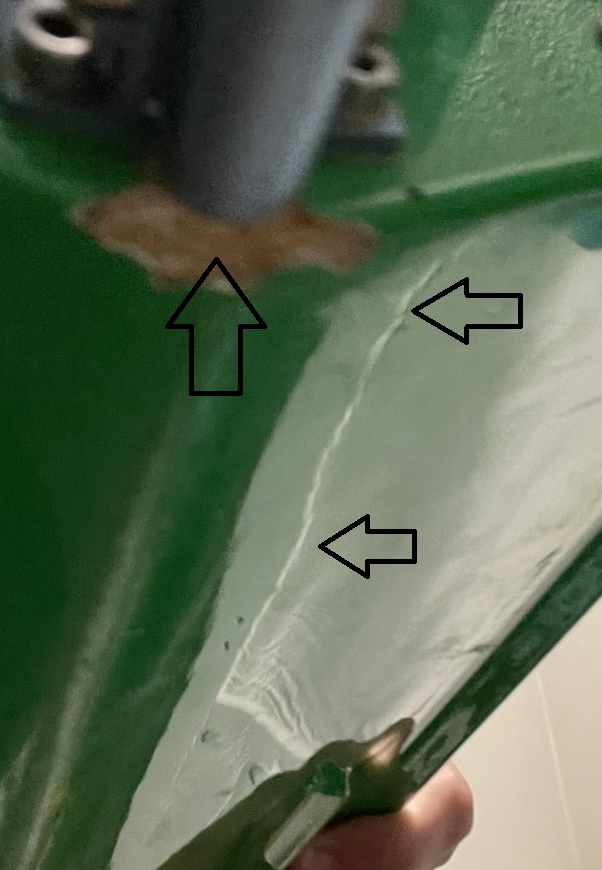

Can you post a picture of the cracks?

In general, cracks can't just be covered, it won't hold. You have to grind it out and fill with epoxy and fiber particles. Ideally, place new fiber over top. Gel coat is just a final finish but has no structural support.

You have to prep the exposed work area with acetone, needs a good wipe down to soften up the original epoxy and prepare for a bond with the new.

Batteries, I'd just wedge 'em down with foam pieces propped under the hull. Velcro works until it gets wet, and then it will deteriorate. In case of a hard flip they will come loose though. You can try battery trays with straps. Might have to custom make some out of ply-wood and epoxy them in. Make sure you seal wood with epoxy.

Are all of these actuals cracks?

Can you post a picture of the cracks?

In general, cracks can't just be covered, it won't hold. You have to grind it out and fill with epoxy and fiber particles. Ideally, place new fiber over top. Gel coat is just a final finish but has no structural support.

You have to prep the exposed work area with acetone, needs a good wipe down to soften up the original epoxy and prepare for a bond with the new.

Batteries, I'd just wedge 'em down with foam pieces propped under the hull. Velcro works until it gets wet, and then it will deteriorate. In case of a hard flip they will come loose though. You can try battery trays with straps. Might have to custom make some out of ply-wood and epoxy them in. Make sure you seal wood with epoxy.

Are all of these actuals cracks?