FireDrake001

Active Member

- Messages

- 367

- Reaction score

- 316

- Arrma RC's

- Typhon Mega

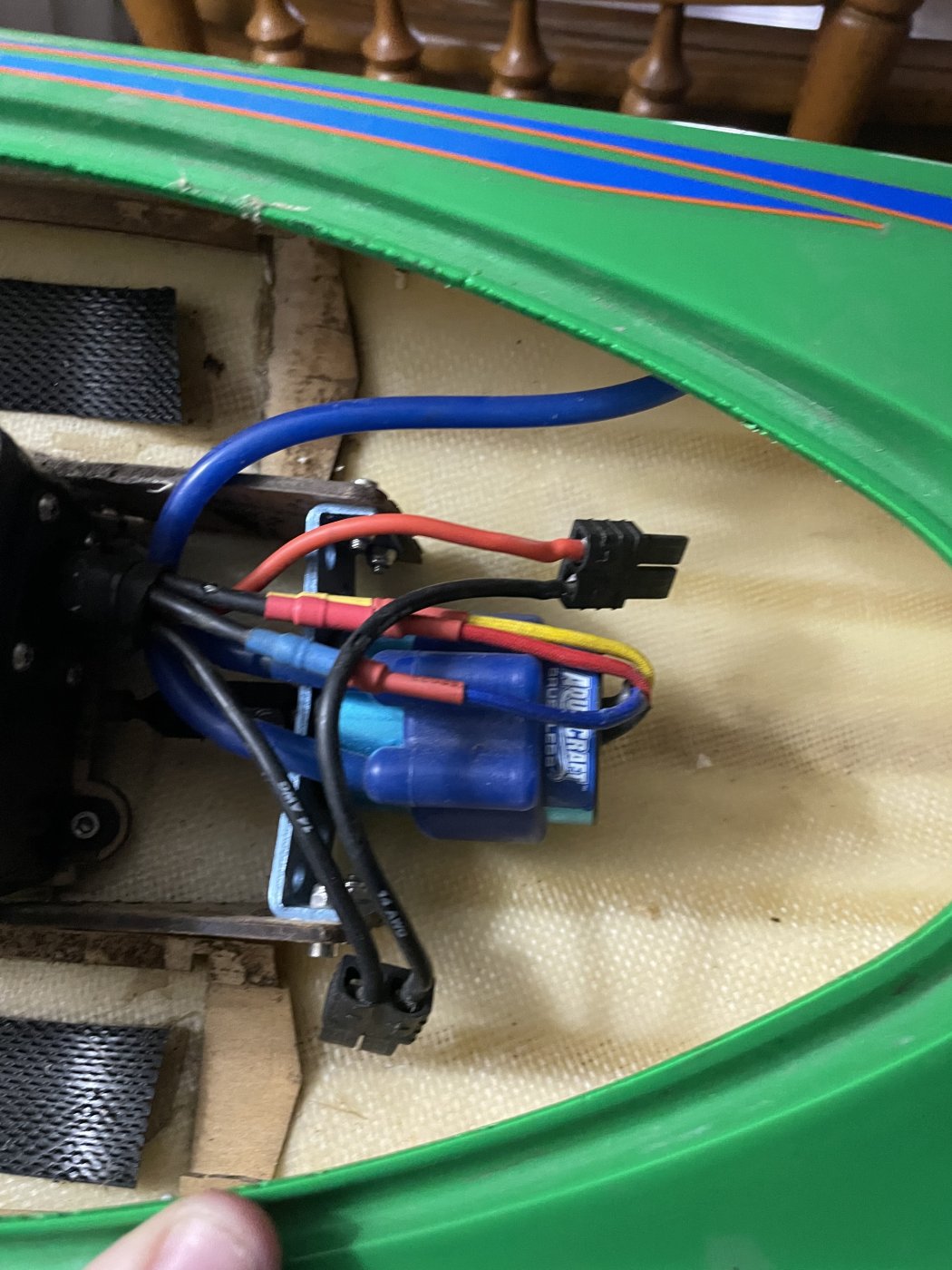

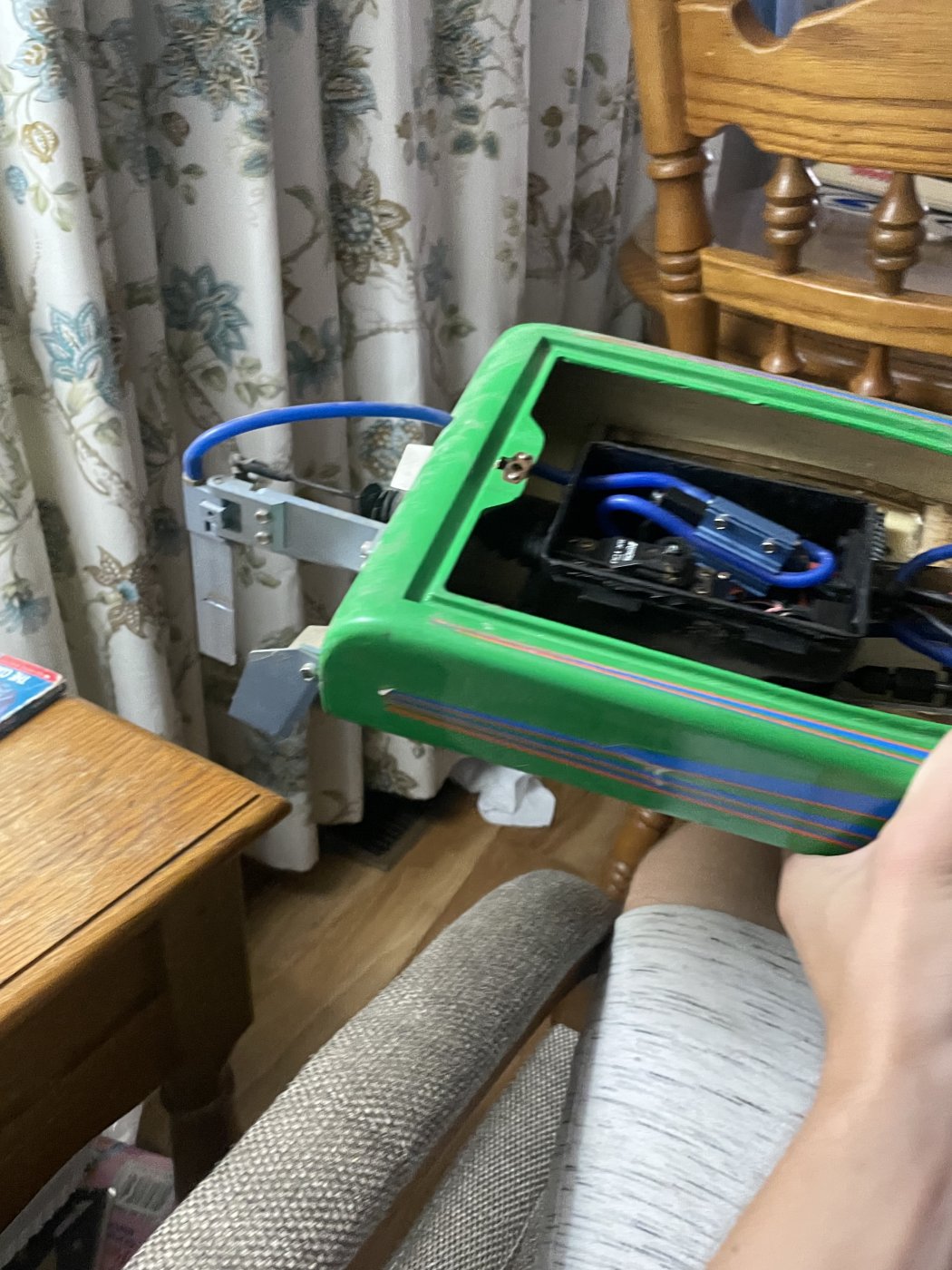

I got a Brushless boat called a Supervee from a coworker recentry. Does anyone know how to calibrate it? Plus at the back under the rudder it has some damage and needs some patchwork. Does anyone have some recommended ideas for solutions to help this boat get back in shape after many years of no use?

Last edited: