DesertRC928

Fairly New Member

- Messages

- 9

- Reaction score

- 16

I’m just getting back into this hobby. Recently bought my first arrma at my local hobby shop. Decided to go with the 1/7 Big Rock 6s. Very happy with it so far. To me planning, upgrading, and wrenching on these things is just as fun as running them. I still have a lot to learn about this platform so I’m hoping for some guidance as I build this thing up.

Goal of this build

Build a bulletproof desert basher! I live in Arizona and my backyard is literally the desert that is outside of city limits. So I want it to be setup to handle in the sand, not overheat in the hot climate, and be able to take a beating without constantly breaking.

Current upgrades

Incoming parts ordered.

I’m going to play around with different diff oil weights to figure out what I like. I think I’ll start with

Center diff: 500,000

Front diff: 80,000 (maybe eventually run a limited slip front diff?)

Rear diff: 30,000

Open to any and all diff tuning suggestions.

Current charger and battery setup. Bought come cheap lipos from amazon to try out. I’ll probably eventually grab some CHNL lipos after reading some on this forum.

Future mods??? (Will update as we go)

Honestly I’ll probably end up eventually upgrading everything haha! I’m open to suggestions from you guys. First I want to upgrade all the most common weak points, stock up on the most commonly broken spare/wear item parts, then upgrade the fun go fast stuff.

Questions for you guys.

Aside from the parts I have incoming what are the most commonly broken parts and things to upgrade first? I’m assuming maybe shock towers next?

What spare parts would you recommend keeping on hand? The stuff that inevitably breaks.

I live in a very hot climate. What motor and esc fans would be best to keep it from overheating?

Is there any benefit to running a limited slip front diff? I want it to track pretty straight under power in the sand and still turn tight. I know there is a give and take balance to this. Just looking for a best place to start.

Goal of this build

Build a bulletproof desert basher! I live in Arizona and my backyard is literally the desert that is outside of city limits. So I want it to be setup to handle in the sand, not overheat in the hot climate, and be able to take a beating without constantly breaking.

Current upgrades

- Savox monster sb2290sg servo

- Castle bec (8.4 volt output for servo)

Incoming parts ordered.

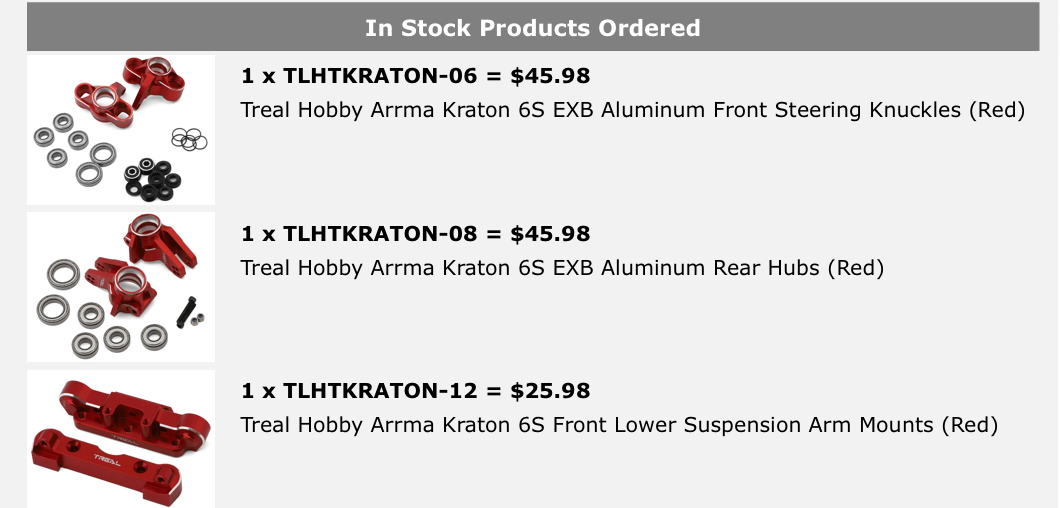

- Treal aluminum front/rear hubs (these have 3 bearings per hub 2 small and 1 “oversized” inner) My big rock eats stock inner rear bearings. I’ve killed about 4 with about 15 packs through the RC.

- Treal aluminum front lower suspension arm mounts.

- Arrma EXB aluminum front upper suspension mount

- hobbywing LED program card (just more convenient for messing with esc settings)

- Different diff oil weights: 30,000, 80,000, 500,000 cst.

I’m going to play around with different diff oil weights to figure out what I like. I think I’ll start with

Center diff: 500,000

Front diff: 80,000 (maybe eventually run a limited slip front diff?)

Rear diff: 30,000

Open to any and all diff tuning suggestions.

Current charger and battery setup. Bought come cheap lipos from amazon to try out. I’ll probably eventually grab some CHNL lipos after reading some on this forum.

Future mods??? (Will update as we go)

Honestly I’ll probably end up eventually upgrading everything haha! I’m open to suggestions from you guys. First I want to upgrade all the most common weak points, stock up on the most commonly broken spare/wear item parts, then upgrade the fun go fast stuff.

Questions for you guys.

Aside from the parts I have incoming what are the most commonly broken parts and things to upgrade first? I’m assuming maybe shock towers next?

What spare parts would you recommend keeping on hand? The stuff that inevitably breaks.

I live in a very hot climate. What motor and esc fans would be best to keep it from overheating?

Is there any benefit to running a limited slip front diff? I want it to track pretty straight under power in the sand and still turn tight. I know there is a give and take balance to this. Just looking for a best place to start.