Mopsik_Klopsik

Active Member

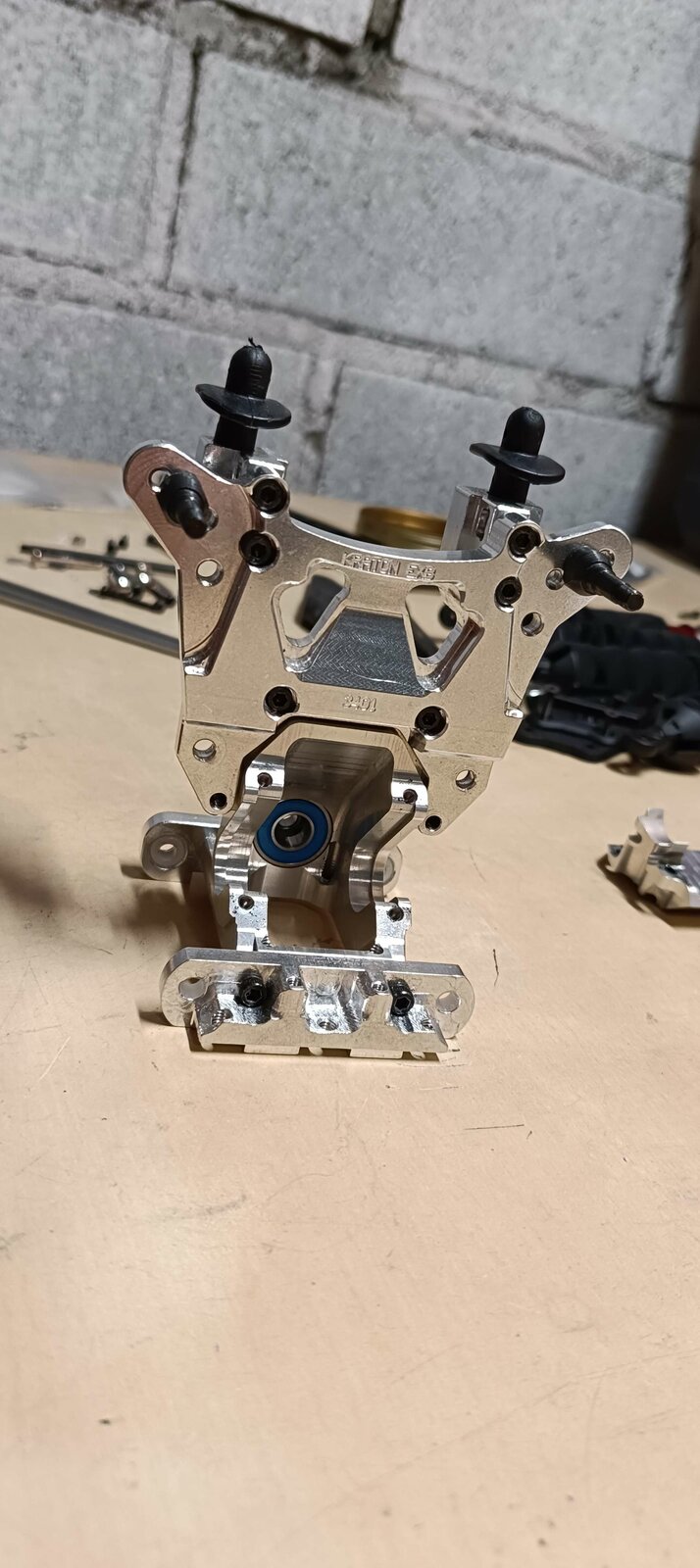

Is it a good idea to glue the bearings into the diff housing? Would it be problematic to dissasemble them? I want to use loctite 270. I have tried a couple of different bearings but only the original ones have tight enough fit. For now the original bearings are fine but I would like not to be dependent on them and be able to use different ones ( available locally ) when these breake.