2015GTRBE

Patrick Bateman ?

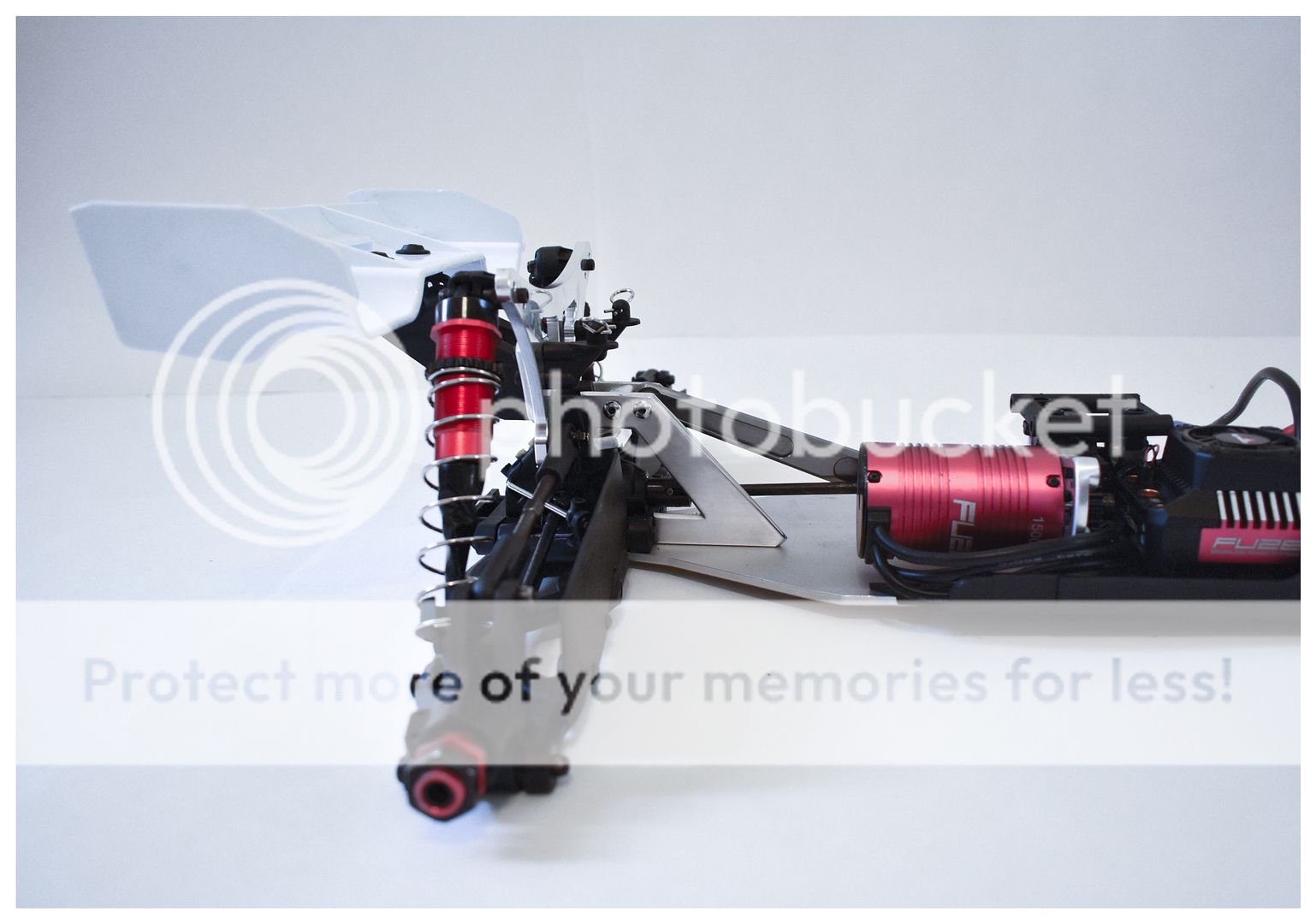

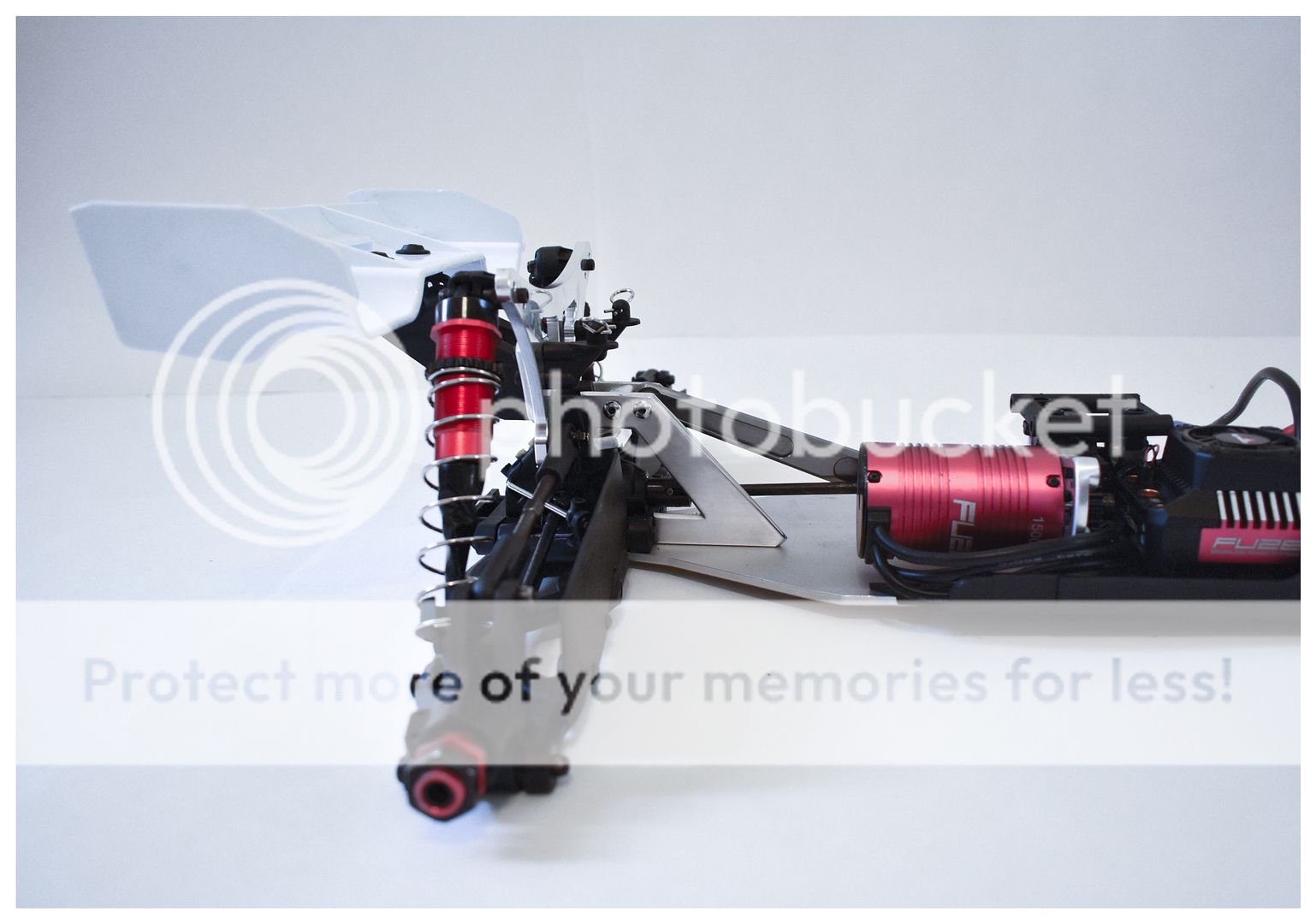

Well I finally won the war against chassis flex  . Little obsessive, but it’s fun to get back to my RC roots of building custom stuff out of limited resources. Anyway, this brace replaces the previous brackets I made and have tighter tolerences. The back lash may be bent hingepins or possibly diff case but I’ll be able to see what’s going on by marks on the chassis, but there is basically zero noticeable flex forward now. The brace uses the Voltsge hobby aluminum wingmount as a hard mount, and the lower part of the brace is press fit to the hinge pin support.

. Little obsessive, but it’s fun to get back to my RC roots of building custom stuff out of limited resources. Anyway, this brace replaces the previous brackets I made and have tighter tolerences. The back lash may be bent hingepins or possibly diff case but I’ll be able to see what’s going on by marks on the chassis, but there is basically zero noticeable flex forward now. The brace uses the Voltsge hobby aluminum wingmount as a hard mount, and the lower part of the brace is press fit to the hinge pin support.

I think it came out pretty nice. Hand brushed with polished edges, polished screws, and waiting on stainless nuts. TP Parts, I’m eyeing you...jk.

I think it came out pretty nice. Hand brushed with polished edges, polished screws, and waiting on stainless nuts. TP Parts, I’m eyeing you...jk.

Last edited: