JustAnOutcast

compulsive over-thinker, I think. 🤔

- Messages

- 278

- Reaction score

- 443

Alright, hopefully I’m entitled to one dumb question a day, so here goes…

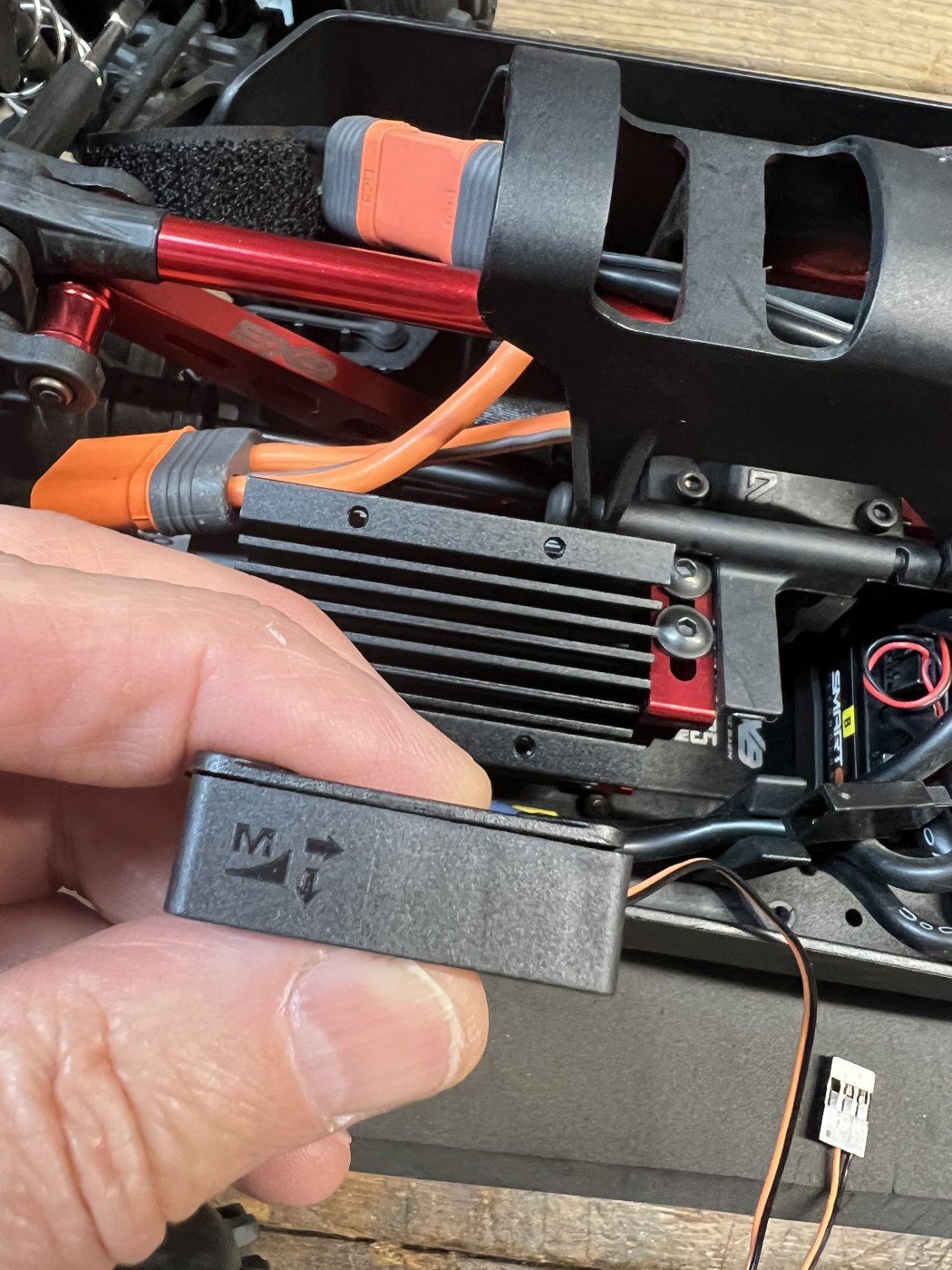

I’ve got the top and bottom figured out, but based on this pic, does it really matter which is front and back? It’s 35mmx35mm, but the M symbol is confusing me.

Thanks for all replies! Even condescending ones will be accepted graciously.

I’ve got the top and bottom figured out, but based on this pic, does it really matter which is front and back? It’s 35mmx35mm, but the M symbol is confusing me.

Thanks for all replies! Even condescending ones will be accepted graciously.