Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Typhon Stripping diff gears

- Thread starter kwalt

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

parcou

Premium Member!

Premium Member

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 6,225

- Reaction score

- 9,127

- Location

- Memphis, TN

- Arrma RC's

- BigRock

- Felony

- Fireteam

- Granite

- Infraction

- Kraton EXB

- Talion EXB

- Typhon TLR

- Vorteks

Hello.Having trouble with my Typhon 3s stripping the rear plastic diff spur gear. It is stripping just a few gears in on place. Could the slipper be to tight, seems to happen at the tracks with several jumps.

Cannot speak directly to yours, but in my 3S my issue was going to belted Trencher tires. Too heavy and went back to non-belted and used the correct 2.8" size tires

Other things I have seen posted.

- Make sure the rear diff is shimmed correctly. In most cases, the shim needs to be moved to the crown/ring gear side. Mine was on the opposite side stock

- Flex in the plastic yoke that encloses the diff. Make sure it is tightened correctly. In some cases, when tightening it down seems the diff does not spin smoothly finding the right spot can be a chore. I personally do not like the plastic and later got the HR metal yoke to be sure it was snugged each time

- Landing jumps on power, or throttle can lead to that as well

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,880

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

Probably already bent the Motor mount. It is weak and too thin. Very common problem with Arrma 4x4 rigs, if you drive hard and crash alot. The plastic spur is junk, if it stripped. Even one tooth. The spur will keep on stripping more and more, once it is damaged. Look over the motor mount. remove it completely and place on a flat surface to evaluate for straightness. The slightest bend or tweak causes loosened misaligned mesh.

Also, use blue Threadlocker on the 2 motor mount screws or the mesh will loosen and gears will slip.

Dirt and debris needs to be cleaned out of the Power Module regularly and often enough.. This can also wear out the gears.

There are $$ upgrades that may or may not help prevent this. Upgraded steel Spur gears and hardened/thicker Motor mounts, etc.

JennysRc.com has stock replacemnt parts for less $$ in some cases.

>>>>> @parcou made a good point there.

Also, use blue Threadlocker on the 2 motor mount screws or the mesh will loosen and gears will slip.

Dirt and debris needs to be cleaned out of the Power Module regularly and often enough.. This can also wear out the gears.

There are $$ upgrades that may or may not help prevent this. Upgraded steel Spur gears and hardened/thicker Motor mounts, etc.

JennysRc.com has stock replacemnt parts for less $$ in some cases.

>>>>> @parcou made a good point there.

Last edited:

parcou

Premium Member!

Premium Member

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 6,225

- Reaction score

- 9,127

- Location

- Memphis, TN

- Arrma RC's

- BigRock

- Felony

- Fireteam

- Granite

- Infraction

- Kraton EXB

- Talion EXB

- Typhon TLR

- Vorteks

^^^^

Good to have the vets here. I forgot about that one. Big one as well...the motor and how it hangs with bad stock support can create that especially hard bashing. Good call-out

Good to have the vets here. I forgot about that one. Big one as well...the motor and how it hangs with bad stock support can create that especially hard bashing. Good call-out

- Messages

- 6,754

- Reaction score

- 12,426

- Location

- ST.LOUIS

- Arrma RC's

- BigRock 4x4

- Mojave

- Notorious

- Senton 6s

- Senton 3s

- Typhon 6s

Slipper adjustments,big heavy tires will do it every time.landing under power also....are you running stock tires???BTW welcome to the forum,,JENNYRC is where we all buy parts from,by far the cheapest,best parts broker..ya can use the 4s metal diffs that are much stronger...turning punch down on esc will also help..could also try the corralled python buggy tires..extremely light an durable..

These buggy tires are much lighter than most all others..like 65grams each if I remember correctly. Much easier on diffs...direct fit on typhons

These buggy tires are much lighter than most all others..like 65grams each if I remember correctly. Much easier on diffs...direct fit on typhons

Attachments

- Messages

- 6,173

- Reaction score

- 9,032

- Location

- Illinois

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton EXB

- Talion

- Typhon 6s

- Typhon TLR

How’s the traction and longevity?corralled python buggy tires

I would loosen the slipper and stop landing jumps on throttle.Having trouble with my Typhon 3s stripping the rear plastic diff spur gear. It is stripping just a few gears in on place. Could the slipper be to tight, seems to happen at the tracks with several jumps.

beenjammin

Fairly New Member

- Messages

- 4

- Reaction score

- 7

Is it possible you’re setting the gear mesh wrong? If the mounting plate isn’t bent, and the mesh is set properly with locktight, then you should be getting many runs in before it ever becomes an issue.

Could always get a metal spur gear

Could always get a metal spur gear

- Messages

- 6,173

- Reaction score

- 9,032

- Location

- Illinois

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton EXB

- Talion

- Typhon 6s

- Typhon TLR

I think he’s talking about the diff ring gear.Is it possible you’re setting the gear mesh wrong? If the mounting plate isn’t bent, and the mesh is set properly with locktight, then you should be getting many runs in before it ever becomes an issue.

Could always get a metal spur gear

- Messages

- 6,754

- Reaction score

- 12,426

- Location

- ST.LOUIS

- Arrma RC's

- BigRock 4x4

- Mojave

- Notorious

- Senton 6s

- Senton 3s

- Typhon 6s

Good traction,I would always gear mine to 65ish mph gearing,an I would destroy all buggy tires...I would always reglue an vent them soon as I received them....I've tried about all buggy tires an these corrally ones hung in there....grp makes some good buggy tires alsoHow’s the traction and longevity?

I would loosen the slipper and stop landing jumps on throttle.

RCbuzz

Very Active Member

- Messages

- 2,901

- Reaction score

- 5,102

- Arrma RC's

- Granite

- Kraton 8S

- Kraton 6s

- Mojave EXB

- Senton 3s

Oddly enough we don't go through many spurs after sealing the power module on every 3S rig we have. The power modules stay MUCH cleaner, we also have not smoked any motor bearings since... Arrma should have designed these as sealed units even if they had to shrink the spur a little.... I have told them this multiple times, they don't seem to care... I guess motors are cheaper to them.Probably already bent the Motor mount. It is weak and too thin. Very common problem with Arrma 4x4 rigs, if you drive hard and crash alot. The plastic spur is junk, if it stripped. Even one tooth. The spur will keep on stripping more and more, once it is damaged. Look over the motor mount. remove it completely and place on a flat surface to evaluate for straightness. The slightest bend or tweak causes loosened misaligned mesh.

Also, use blue Threadlocker on the 2 motor mount screws or the mesh will loosen and gears will slip.

Dirt and debris needs to be cleaned out of the Power Module regularly and often enough.. This can also wear out the gears.

There are $$ upgrades that may or may not help prevent this. Upgraded steel Spur gears and hardened/thicker Motor mounts, etc.

JennysRc.com has stock replacemnt parts for less $$ in some cases.

>>>>> @parcou made a good point there.

As the for the plastic diffs, they are a pain sometimes. I have blown through a few... What's really odd is it seems more vehicle specific. In other words, after we 100% rebuilt one of our last granites it has been great, in fact, I think we are about 10+ packs in and nothing has broken (even the plastic spur looks great).... A couple skate park bashes in there too..

I have another granite that didn't even make two packs and the diff was trashed.. again.. On that one I replaced the Diff and Input and it felt great. I am wondering if the plastic yoke is the culprit.. Perhaps since it was not new all the flexing has weakened the plastic to the point where the entire diff assembly flexes too much under load? Just a theory... The plastic yoke seems so stout though.. Maybe it is a plastics quality thing... They should have gone metal.

Last edited:

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,880

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

If its the Diff's ring gear you could always spend $75.I think he’s talking about the diff ring gear.

RCbuzz

Very Active Member

- Messages

- 2,901

- Reaction score

- 5,102

- Arrma RC's

- Granite

- Kraton 8S

- Kraton 6s

- Mojave EXB

- Senton 3s

That is the reason we still use plasticIf its the Diff's ring gear you could always spend $75.rolleyes

on a machined metal one. Stay away from the sintered pot metal ones however. They chip and crack.

Arrma must be making a fortune off those $75 3S CNC Metal Diffs (each).

On the plus side I hear the sintered 4S diffs (that also work on 3S rigs) are very durable. Those assemblies are only $65 Ea.

parcou

Premium Member!

Premium Member

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 6,225

- Reaction score

- 9,127

- Location

- Memphis, TN

- Arrma RC's

- BigRock

- Felony

- Fireteam

- Granite

- Infraction

- Kraton EXB

- Talion EXB

- Typhon TLR

- Vorteks

It is a 70/30 like factor but on the 3S rigs like the BR & Granite using the plastic rear diff with the metal HR yoke worked well for me to remove that plastic yoke flex and save the input gear. Many like the HR yoke and reading the same older post few do not.That is the reason we still use plastic.

Arrma must be making a fortune off those $75 3S CNC Metal Diffs (each).

On the plus side I hear the sintered 4S diffs (that also work on 3S rigs) are very durable. Those assemblies are only $65 Ea.

For $30 I find it a win before going the all-metal rear Arrma direction. Lots of good reads on it here.

Velodromed

Snatching defeat from the jaws of victory!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 7,758

- Reaction score

- 13,924

- Location

- San Antonio, TX

- Arrma RC's

- BigRock 4x4

- Granite

- Kraton 6s

- Kraton 4s

- Notorious

- Outcast 4s

- Vorteks

- Voltage

- Infraction 4x4

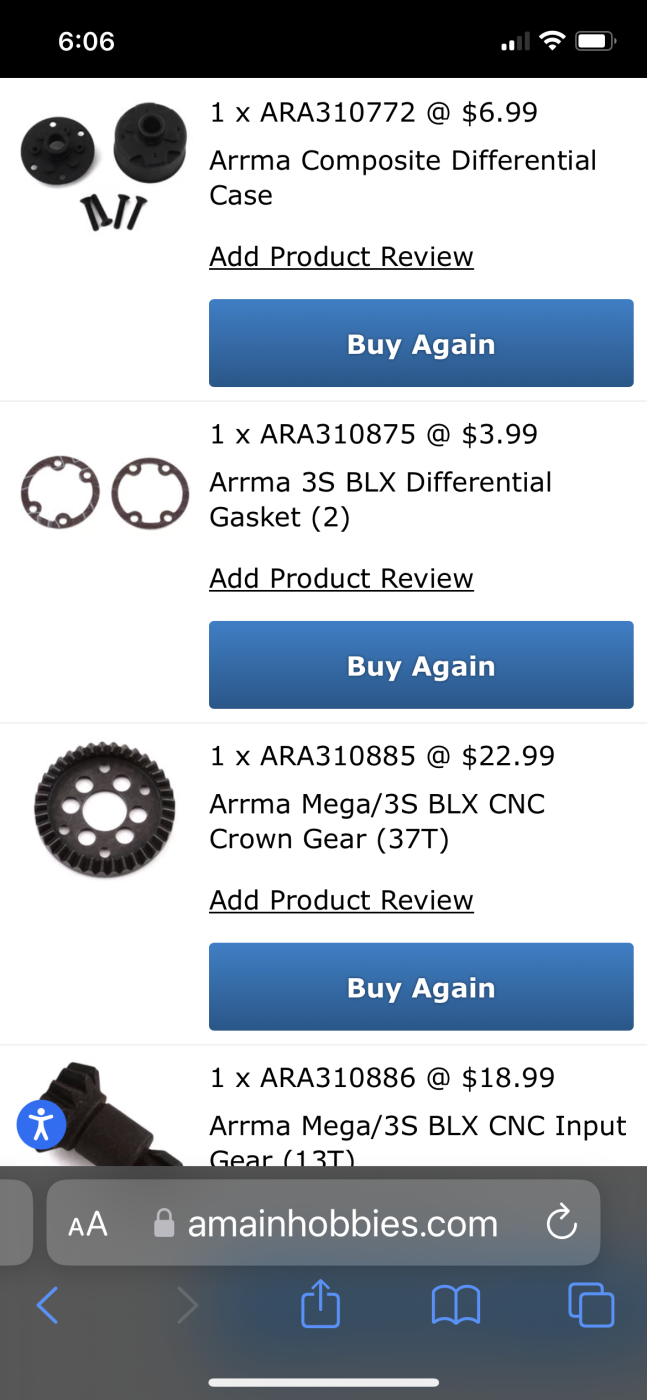

For $55 can build your own cnc diff, using the internal gears and plastic yoke from one of the ones you stripped the ring gear on. This way you can choose the oil viscosity you prefer and fill it up properly.

- Messages

- 3,035

- Reaction score

- 5,803

- Location

- Mechanicsville, MD

- Arrma RC's

- Infraction

- Kraton 6s

- Typhon 3s

- Infraction 4x4

The Corally wheels are weak: they have been shown to break on jumps. I replaced the ones on my Corally Radix6 with solid disc wheels.Slipper adjustments,big heavy tires will do it every time.landing under power also....are you running stock tires???BTW welcome to the forum,,JENNYRC is where we all buy parts from,by far the cheapest,best parts broker..ya can use the 4s metal diffs that are much stronger...turning punch down on esc will also help..could also try the corralled python buggy tires..extremely light an durable..

These buggy tires are much lighter than most all others..like 65grams each if I remember correctly. Much easier on diffs...direct fit on typhons

Badmofreaker

Very Active Member

- Messages

- 716

- Reaction score

- 1,275

- Arrma RC's

- Typhon 6s

I upgraded to the hot racing metal gears and case and haven't had any problems since and I've run up to 6s so far. I also put in a spool and eliminated the slipperHaving trouble with my Typhon 3s stripping the rear plastic diff spur gear. It is stripping just a few gears in on place. Could the slipper be to tight, seems to happen at the tracks with several jumps.

Similar threads

- Replies

- 8

- Views

- 227