332_RC

Very Active Member

- Messages

- 1,889

- Reaction score

- 5,020

- Location

- USA, Georgia

- Arrma RC's

- Gorgon

- Infraction

- Kraton 6s

- Notorious

- Senton 3s

- Infraction 4x4

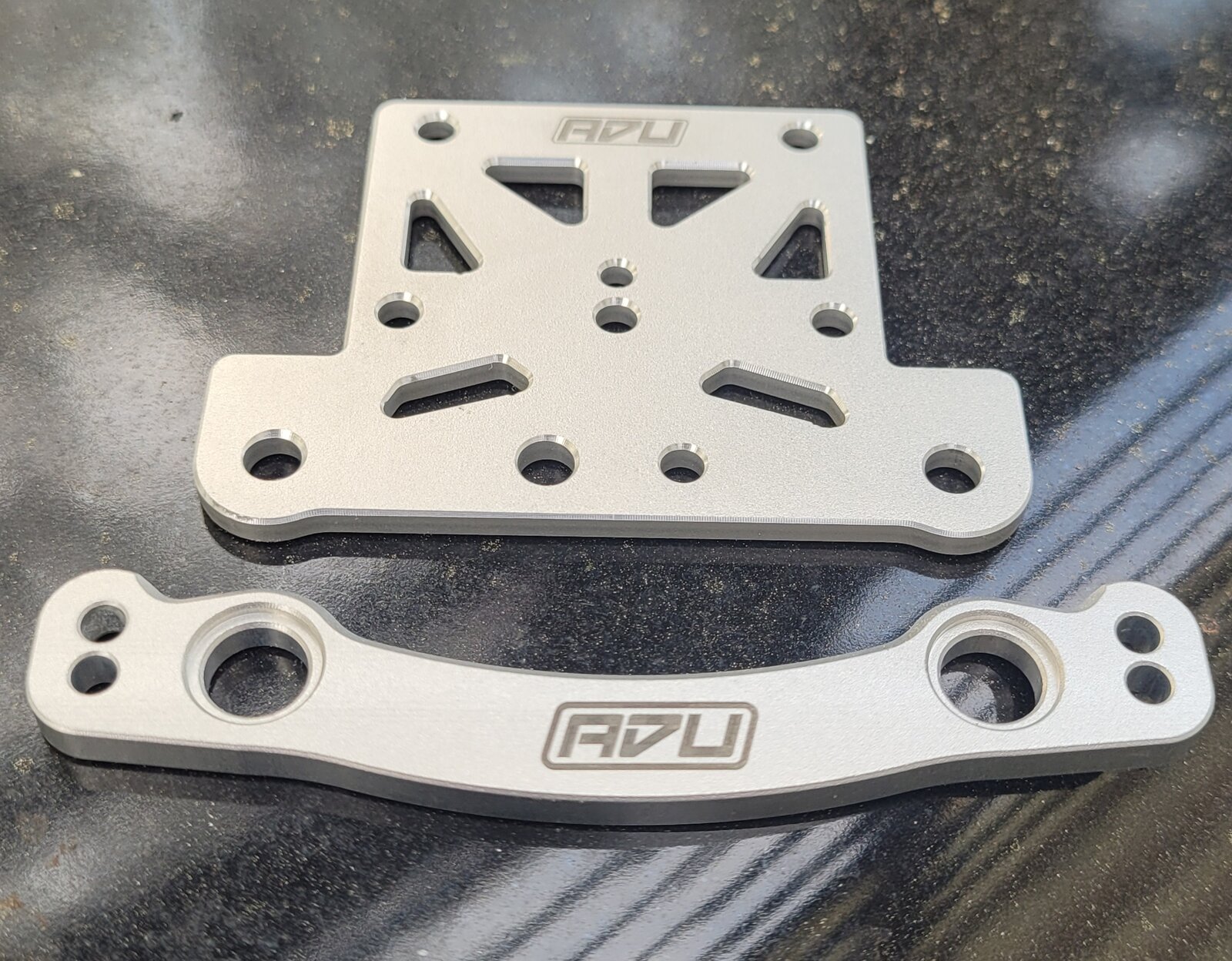

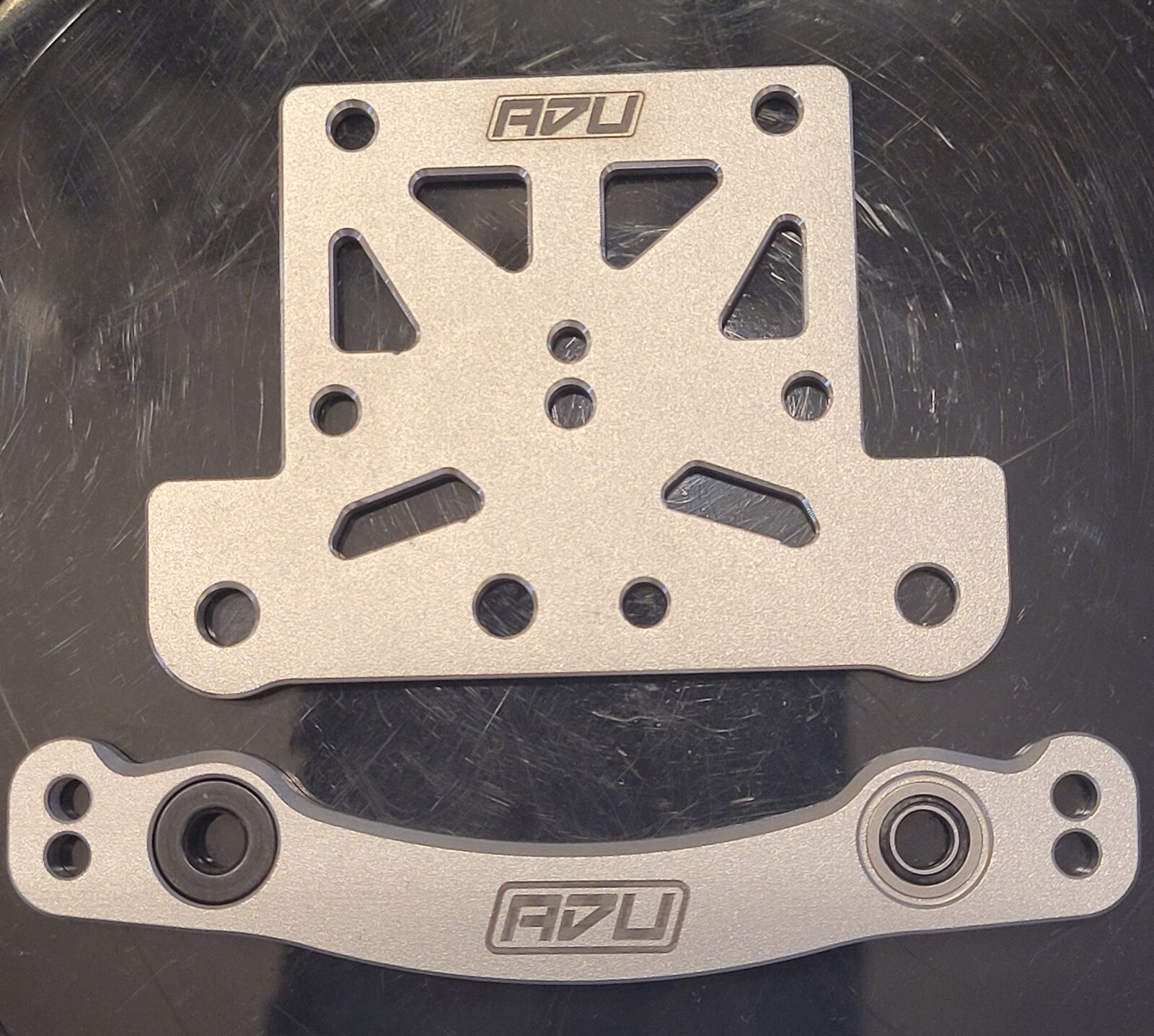

I took a chance & ordered these. They look good. Wanted 7075 & silver. Finally came today. Not ADU's fault. Postal. Anyways here's some pics. The ackerman plate (2nd pic) fits the stock bushing but a slight play as a flanged bushing is really snug & no play. It's also 4mm thick with a 1mm deep step for the bushings & stock step pins. 1st pic is in sunlight. 4mm or 3mm hole in the top plate for any combo of chassis brace.