The Bean

Very Active Member

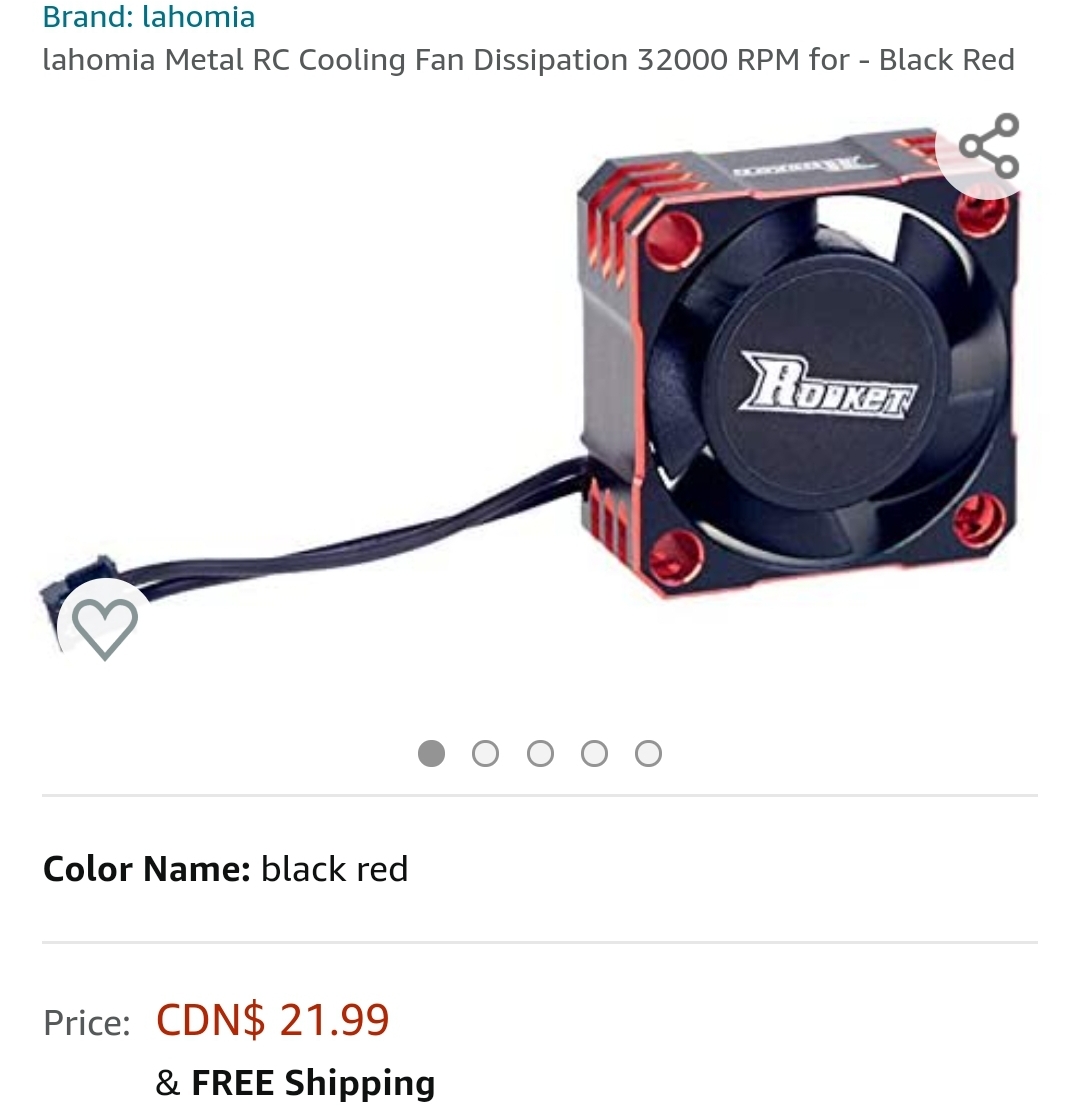

The last, and only time I got a cooling heatsink + fan, it fell apart after only half a year of 'light' bashing (just bumpy surfaces, no jumps). Both fans barely worked after a month, and a bit later, it all fell apart. Guess wich brand it was

That was with light bashing and a PLASTIC CHASSIS, so it should've been the best case scenario for fan drability.

So, how durable are for example Yeah Racing fans? Assume I'll be using it with a metal chassis 1:8 6s vehicle on skate parks. Should I get a cooler for cooling, or should I spend some more for a larger motor for less heat?

That was with light bashing and a PLASTIC CHASSIS, so it should've been the best case scenario for fan drability.

So, how durable are for example Yeah Racing fans? Assume I'll be using it with a metal chassis 1:8 6s vehicle on skate parks. Should I get a cooler for cooling, or should I spend some more for a larger motor for less heat?