RCbuzz

Very Active Member

- Messages

- 2,902

- Reaction score

- 5,106

- Arrma RC's

- Granite

- Kraton 8S

- Kraton 6s

- Mojave EXB

- Senton 3s

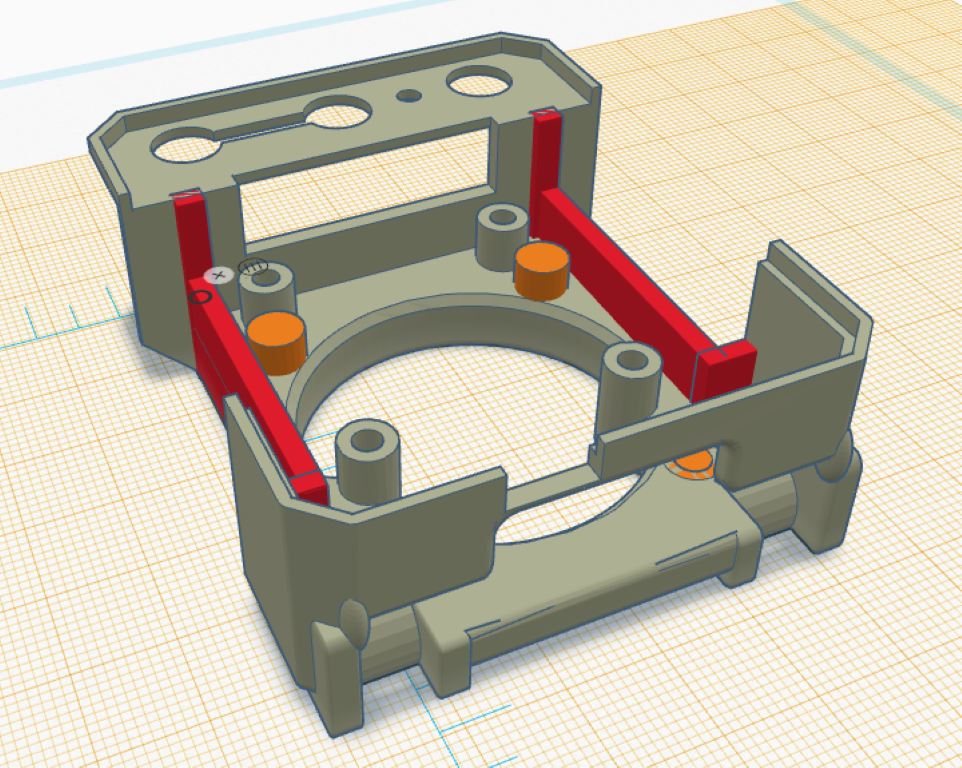

I have always been surprised there was no 3D Printed HobbyWing 40mm Max6 G1 ESC Covers to try out (there are Max5 variants on Thingiverse).

To my surprise a design showed up for the Max6 G2, huge shoutout to SirBeck58 for creating and sharing this (https://www.thingiverse.com/thing:6420721).

It got me thinking... I could probably modify that design to fit a Max6 G1.. This is how it started.. 8 hours into it I have realized a few things.

1. I probably should have started from scratch , as it turns out modifying an existing design has its own challenges.

, as it turns out modifying an existing design has its own challenges.

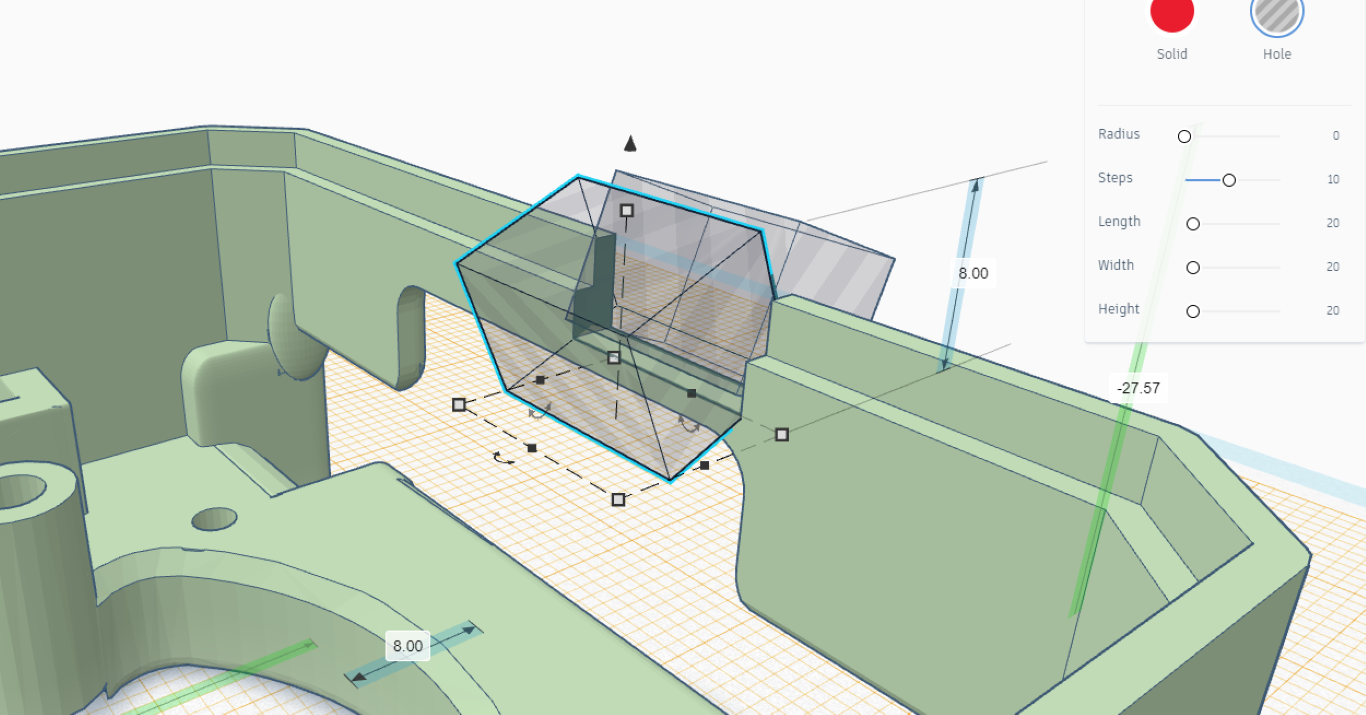

2. Print files on Thingiverse (or other sites) are not design ready and import as a mesh with a thousands of triangles.

3. Uploading an existing 3D print file into TinkerCad will give you a leg up and smooth out the design and give you more solids to work with. <-- Thank you @dure16 for pointing this out.

2. Give plenty of respect to 3D designers, it is a handful.

2. My print bed is having adhesion issues even with glue stick.... Adding more glue stick...

Adding more glue stick...

Things I have changed in the design for the 40mm Hobbywing Max6 G1 Shroud/Cover.

1. Shrunk the holes for the 40mm fan down to 2.7mm so you don't have to use brass inserts (screw the fan directly to the cover).

2. Cut out a section on the front near the motor plugs for the Max6 G1 Heatsink (designed differently than the Max6 G2)

3. Added some strength to the motor plug face.

4. Changed up the back end that protects the capacitors to allow the wires to exit out the top of the cover.

5. Rounded edges all over the model to prevent wire edge wear.

6. Adjusted the sides to fit the Max6 G1 Heatsink.

7. Thickened up the rear of the cover and added a couple hold tabs.

8. Switched around the Fan connection and LED holes.

Running a test print now.

To my surprise a design showed up for the Max6 G2, huge shoutout to SirBeck58 for creating and sharing this (https://www.thingiverse.com/thing:6420721).

It got me thinking... I could probably modify that design to fit a Max6 G1.. This is how it started.. 8 hours into it I have realized a few things.

1. I probably should have started from scratch

2. Print files on Thingiverse (or other sites) are not design ready and import as a mesh with a thousands of triangles.

3. Uploading an existing 3D print file into TinkerCad will give you a leg up and smooth out the design and give you more solids to work with. <-- Thank you @dure16 for pointing this out.

2. Give plenty of respect to 3D designers, it is a handful.

2. My print bed is having adhesion issues even with glue stick....

Things I have changed in the design for the 40mm Hobbywing Max6 G1 Shroud/Cover.

1. Shrunk the holes for the 40mm fan down to 2.7mm so you don't have to use brass inserts (screw the fan directly to the cover).

2. Cut out a section on the front near the motor plugs for the Max6 G1 Heatsink (designed differently than the Max6 G2)

3. Added some strength to the motor plug face.

4. Changed up the back end that protects the capacitors to allow the wires to exit out the top of the cover.

5. Rounded edges all over the model to prevent wire edge wear.

6. Adjusted the sides to fit the Max6 G1 Heatsink.

7. Thickened up the rear of the cover and added a couple hold tabs.

8. Switched around the Fan connection and LED holes.

Running a test print now.

Last edited: