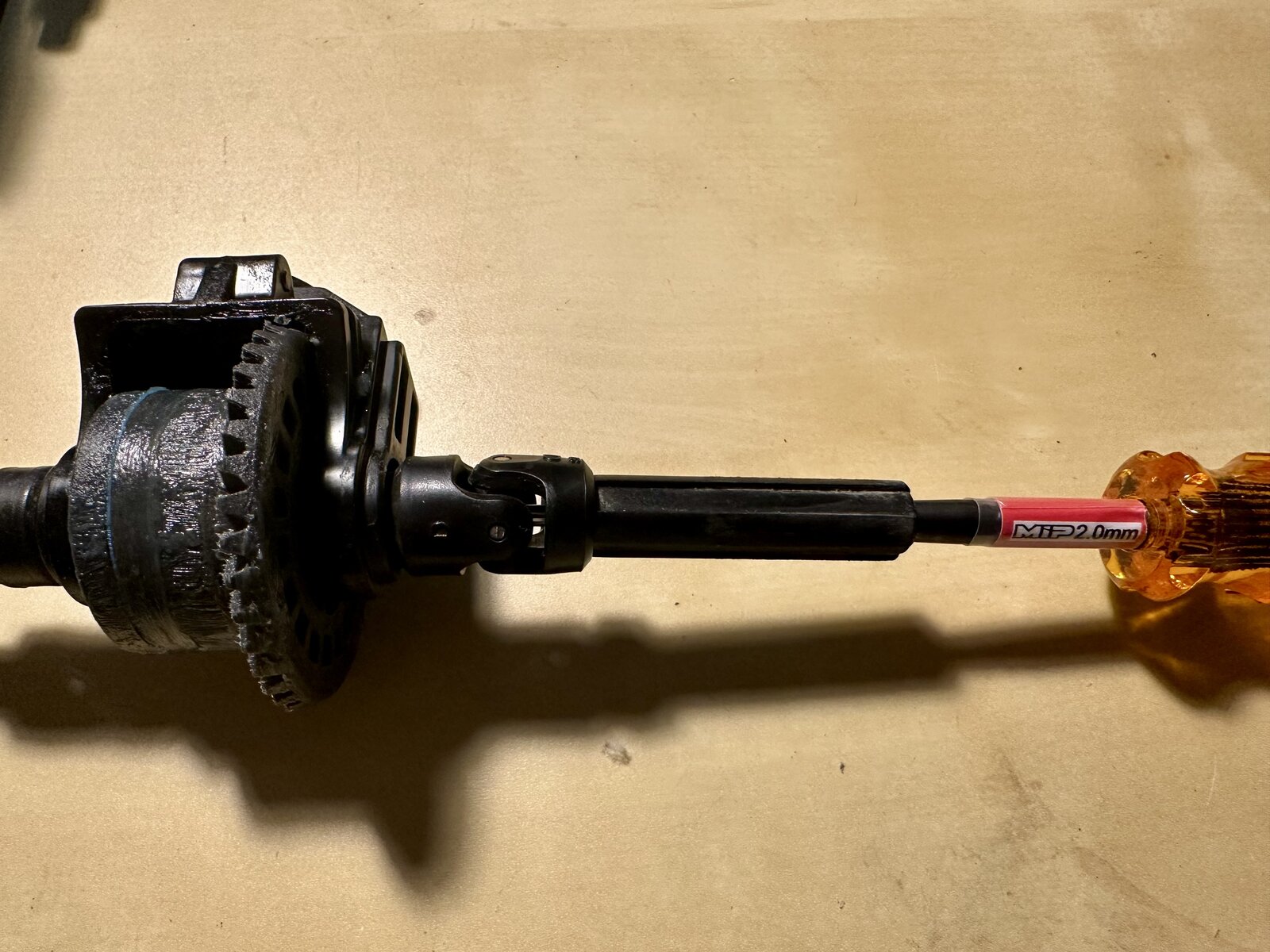

Learned the hard way that the front slider driveshaft is 2 mm longer than the rear.

https://www.arrma-rc.com/en/product/composite-front-slider-driveshaft-set-4x4/ARAC4041.html

https://www.arrma-rc.com/en/product/composite-rear-slider-driveshaft-set-4x4/ARAC4043.html

Would have been fine, except that it is long enough that my MIP 2.0 driver can’t reach the screw.

Any recommendations on what (longer) driver I should get?

https://www.arrma-rc.com/en/product/composite-front-slider-driveshaft-set-4x4/ARAC4041.html

https://www.arrma-rc.com/en/product/composite-rear-slider-driveshaft-set-4x4/ARAC4043.html

Would have been fine, except that it is long enough that my MIP 2.0 driver can’t reach the screw.

Any recommendations on what (longer) driver I should get?

Last edited: