IvanRC

Active Member

Hi Everyone. I just bought my first 1/8th size Truggy the ARRMA Talion. I am completely new so I would appreciate some help.

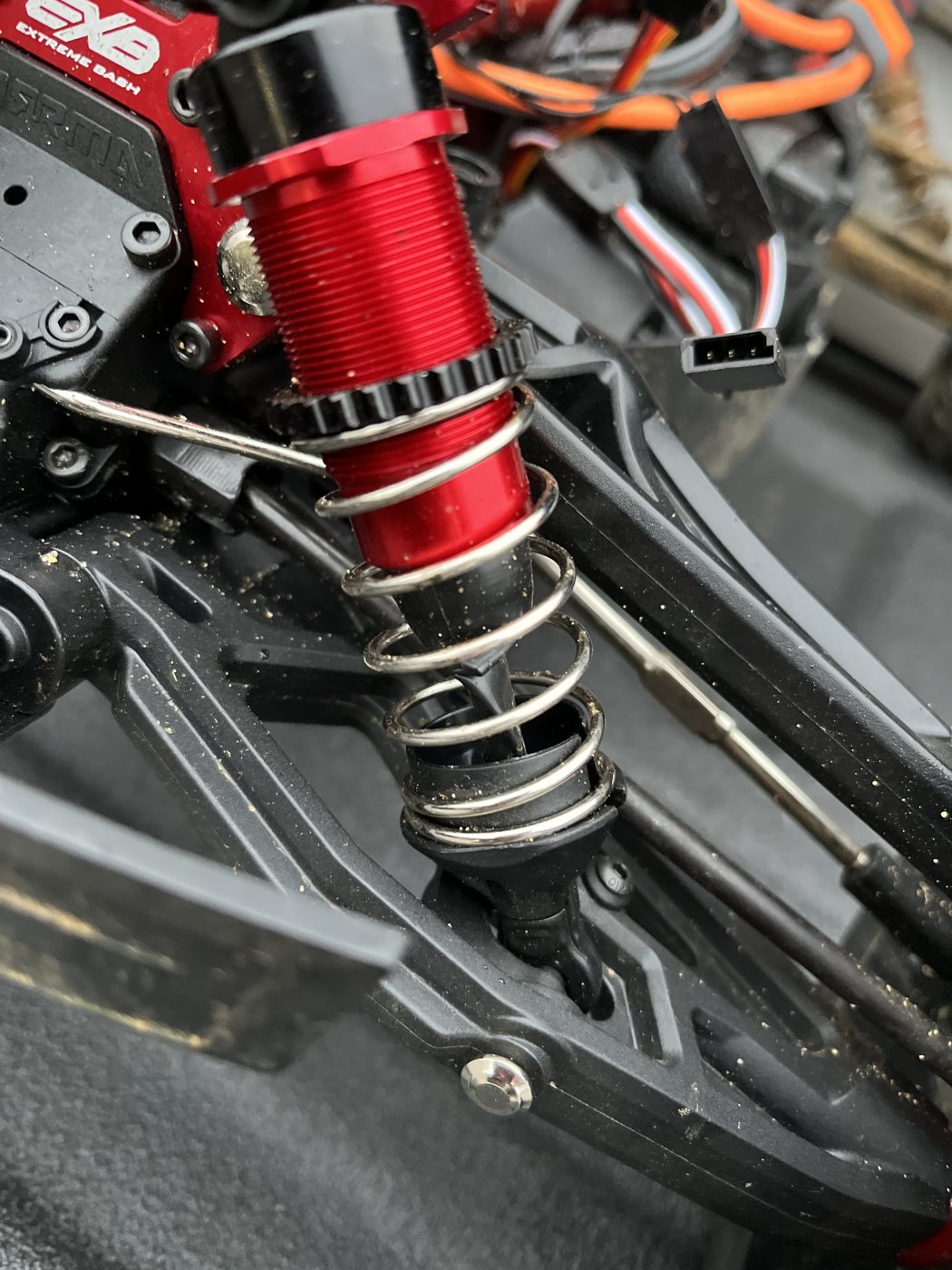

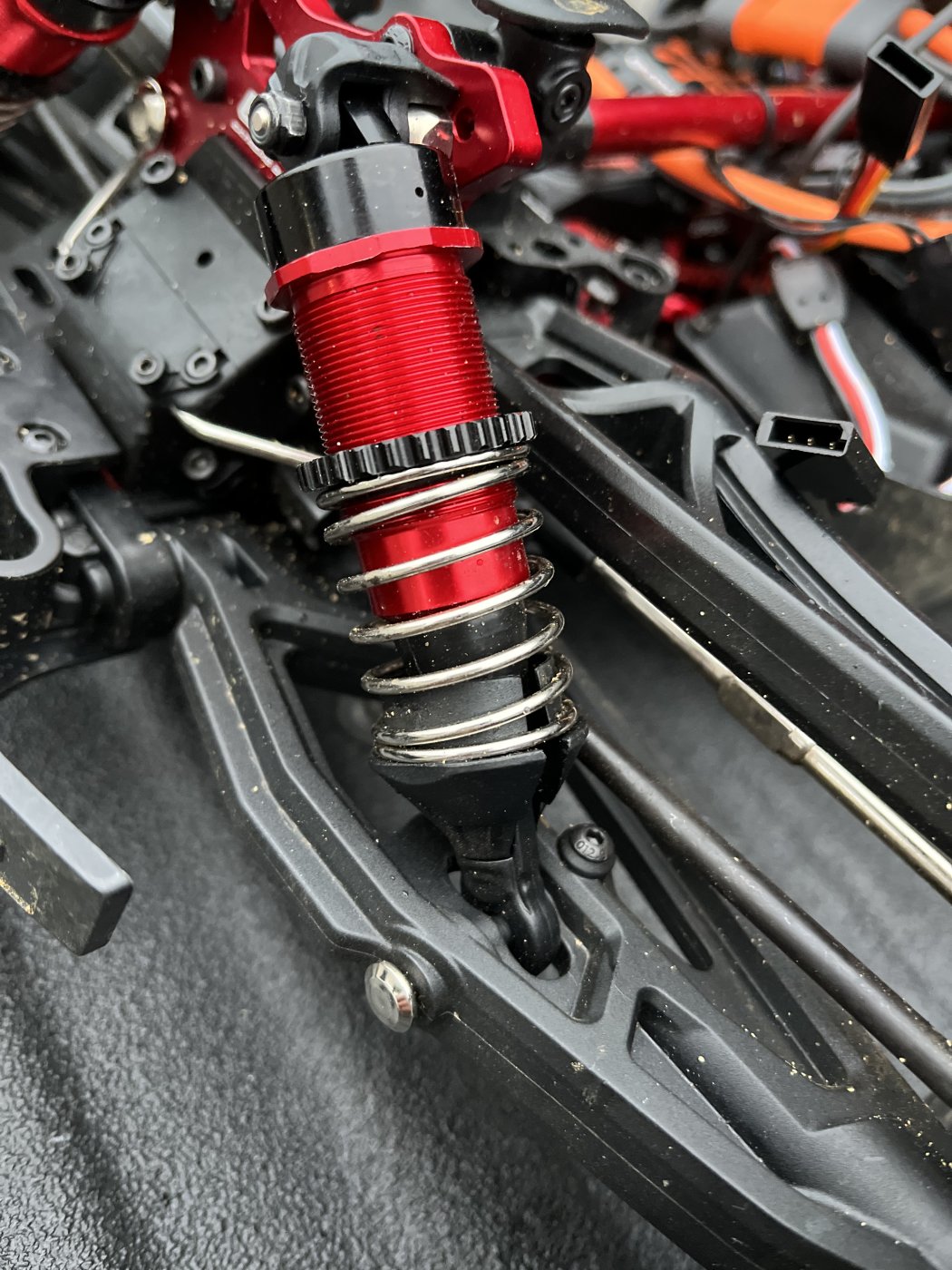

I was running hard in a field and took a small hop. Nothing big at all and now my Drivers side shock gets stuck. I can manually move it up and down but it does not rebound on its own. The truck has only been driven twice.

The wheel turns and the truck drives straight and fine.

And help to fix my shock and would be greatly appreciated. The only advice I was give. Was to check the shock spacer since it looks like it tightened up. But since I am new I have no clue what I am being told to do.

Thank you all in advance.

I was running hard in a field and took a small hop. Nothing big at all and now my Drivers side shock gets stuck. I can manually move it up and down but it does not rebound on its own. The truck has only been driven twice.

The wheel turns and the truck drives straight and fine.

And help to fix my shock and would be greatly appreciated. The only advice I was give. Was to check the shock spacer since it looks like it tightened up. But since I am new I have no clue what I am being told to do.

Thank you all in advance.