Mopsik_Klopsik

Active Member

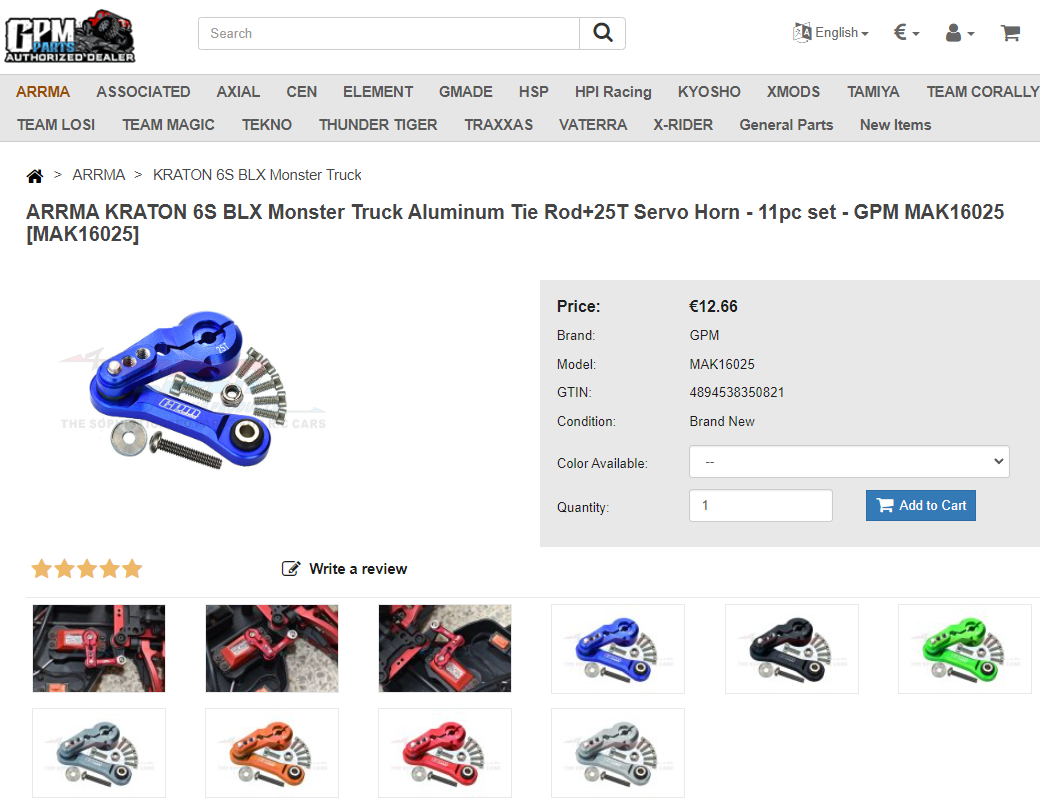

Does someone here have this gpm Servo Horn + Tie Rod set [ MAK16025 ] installed in his kraton/outcast and could send a picture of it. I want to know if there is 90 degree angle between servo horn and tie rod when installed.