- Messages

- 315

- Reaction score

- 1,318

- Arrma RC's

- BigRock

- Fireteam

- Granite

- Infraction

- Kraton EXB

- Notorious

- Thread starter

- #21

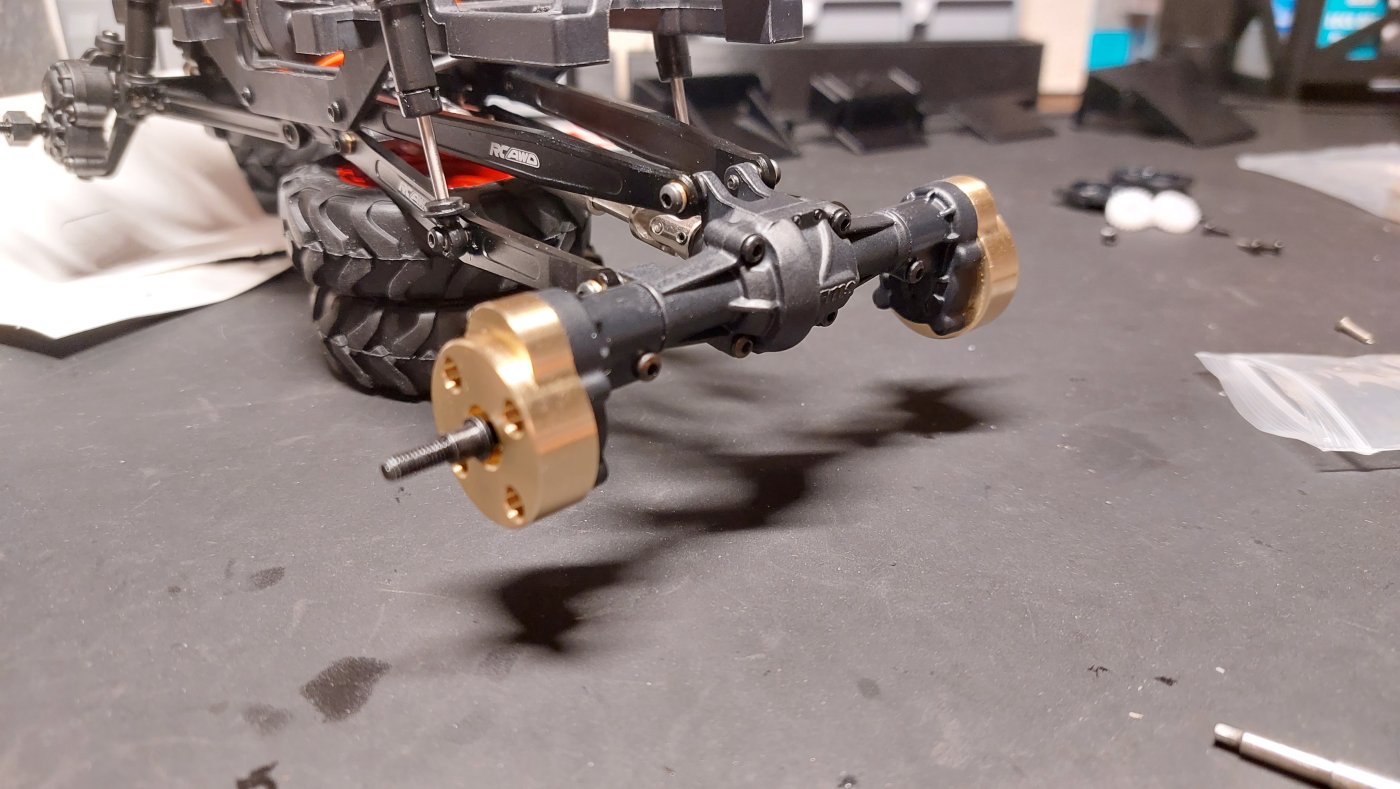

Today nothing but rain ... so I find myself back at the workbench fiddling with tiny hardware again. To improve overall stability and climb ability it is necessary to get the weight as low down as possible. This keeps the truck planted when climbing and crawling over obstacles. Therefore I will be upgrading the axles by adding some nice Injora brass portal covers.

This will be a significant weight gain and performance boost. Almost 100 grams for both axles together.

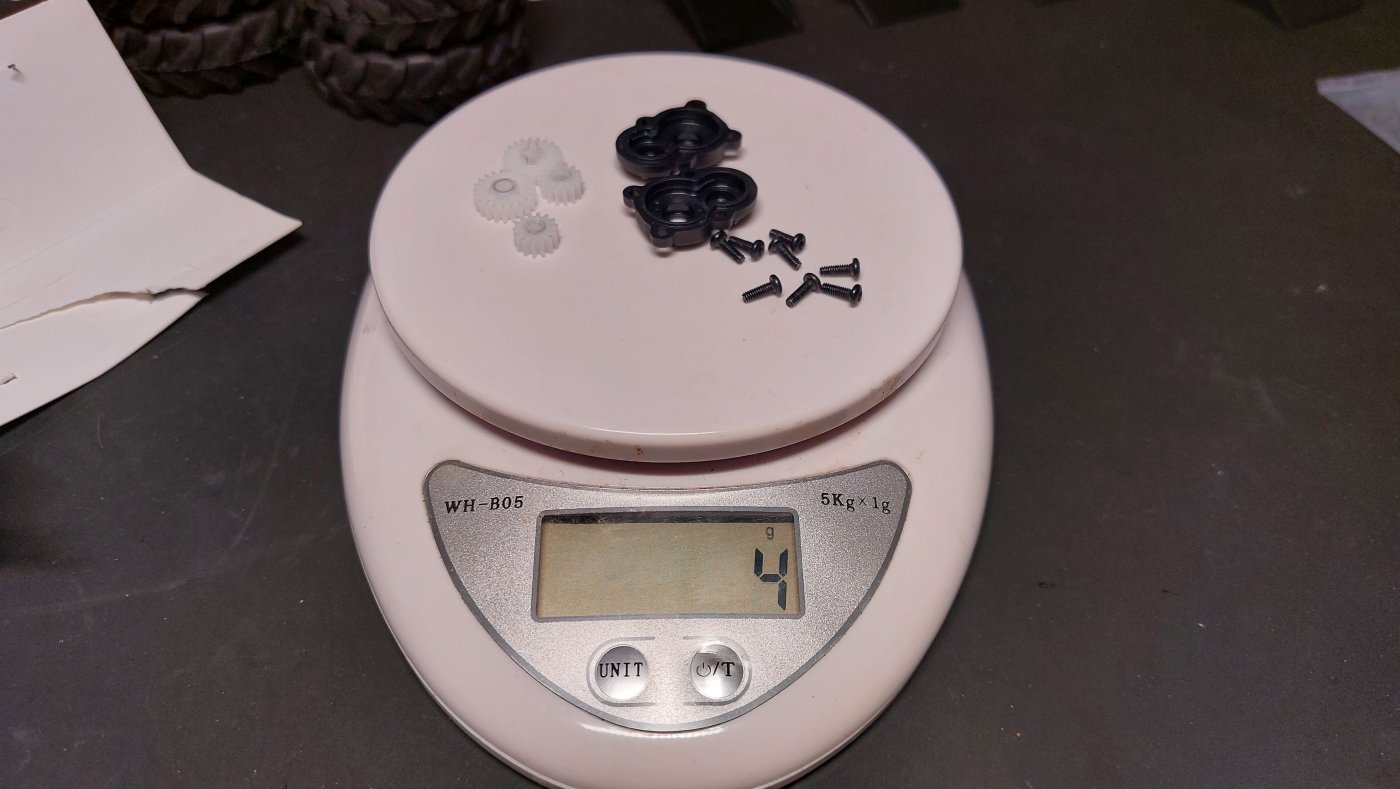

To cope with the added weight of the portal covers I feel it is wise to upgrade the plastic gears to metal ones. I saw on YT mentioned that more recent trucks have metal gears as standard nowadays, unfortunately mine has not. I advise you to check your portals gears when you buy a FCX24 and upgrade to metal gears in case you have plastic gears. Cost is only 12 euro in total for all four corners.

Unfortunately I discovered a lot of stripped screw holes on the inner portal housings on the front as well as the rear. I contacted my hobby store and they will contact FMS about this issue. If not resolved by customer service I will probably be forced to do step 2 of improving the truck much earlier as I have planned. We will see what comes out of it and how the truck will do in current state, perhaps the stripped holes will not be an issue.

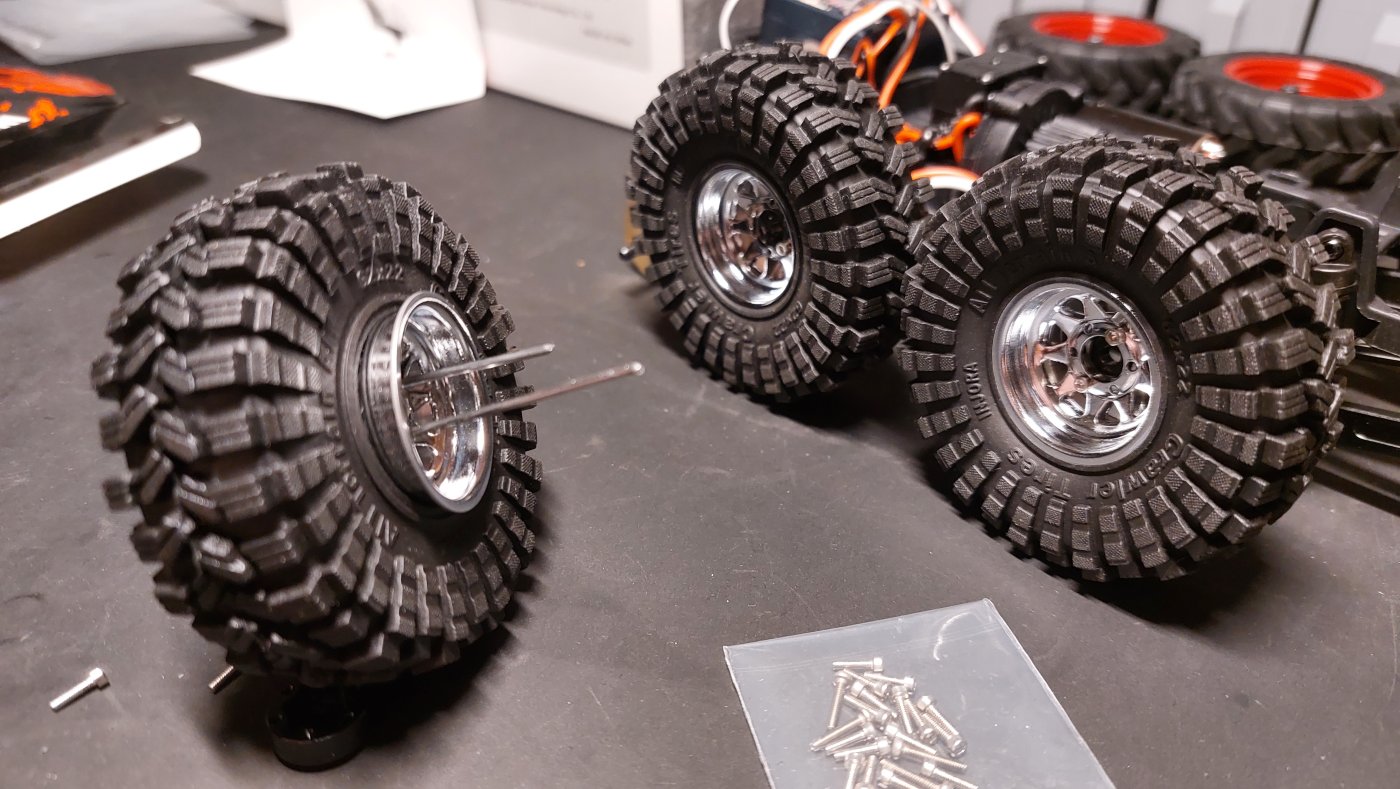

Wheels and tires up next. I got some 1” silver Injora stamped deep dish beadlock wheels and Injora All Terrain crawler tires 22x62mm.

I use a simple U-clip to align the 2 halves of the wheel on assembly. This works really good and is much easier as trying to shift one wheel half when not aligned. The rubber of the tires is really sticky and adjusting the position of the wheel halve by shifting is impossible.

I got good practice with the assembly of the wheels because I did not pay attention and installed the wheel center on the wrong side of the wheels and mounted the tires wrong (directional). So I had to do over 2 wheels. The one wheel on the left is faulty.

Time to quit … and give the eyes and brain some rest. I had a late party last night and I am clearly not having my sharpest moments at this time. Next update with overall pics off all upgrades installed.

This will be a significant weight gain and performance boost. Almost 100 grams for both axles together.

To cope with the added weight of the portal covers I feel it is wise to upgrade the plastic gears to metal ones. I saw on YT mentioned that more recent trucks have metal gears as standard nowadays, unfortunately mine has not. I advise you to check your portals gears when you buy a FCX24 and upgrade to metal gears in case you have plastic gears. Cost is only 12 euro in total for all four corners.

Unfortunately I discovered a lot of stripped screw holes on the inner portal housings on the front as well as the rear. I contacted my hobby store and they will contact FMS about this issue. If not resolved by customer service I will probably be forced to do step 2 of improving the truck much earlier as I have planned. We will see what comes out of it and how the truck will do in current state, perhaps the stripped holes will not be an issue.

Wheels and tires up next. I got some 1” silver Injora stamped deep dish beadlock wheels and Injora All Terrain crawler tires 22x62mm.

I use a simple U-clip to align the 2 halves of the wheel on assembly. This works really good and is much easier as trying to shift one wheel half when not aligned. The rubber of the tires is really sticky and adjusting the position of the wheel halve by shifting is impossible.

I got good practice with the assembly of the wheels because I did not pay attention and installed the wheel center on the wrong side of the wheels and mounted the tires wrong (directional). So I had to do over 2 wheels. The one wheel on the left is faulty.

Time to quit … and give the eyes and brain some rest. I had a late party last night and I am clearly not having my sharpest moments at this time. Next update with overall pics off all upgrades installed.