My work stand was getting on my nerves. It had an adjustable, threaded center column with a set screw to lock the height. At first, the screw kept spinning, until I finally cranked down on the set screw hard enough. Then the connection at the top started spinning, no matter how hard I cranked on the screw. It was very annoying, wanting to rotate away from me while I wrenched on the truck.

So I fixed that problem once and for all today, and it was all "free" in that I just used stuff I already paid for long ago, and had in stock in my shop.

First, I cut a couple pieces of aluminum round bar to length.

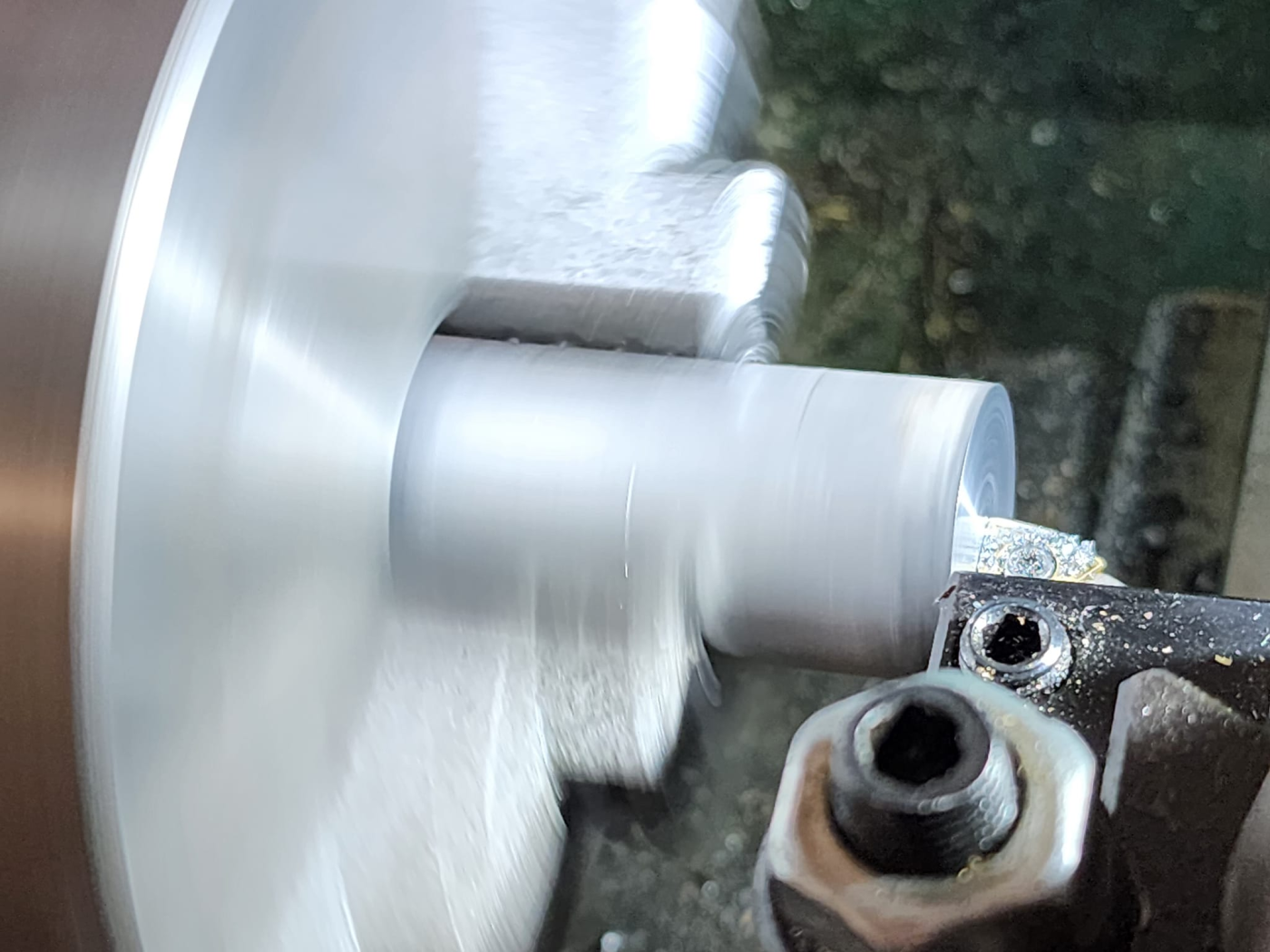

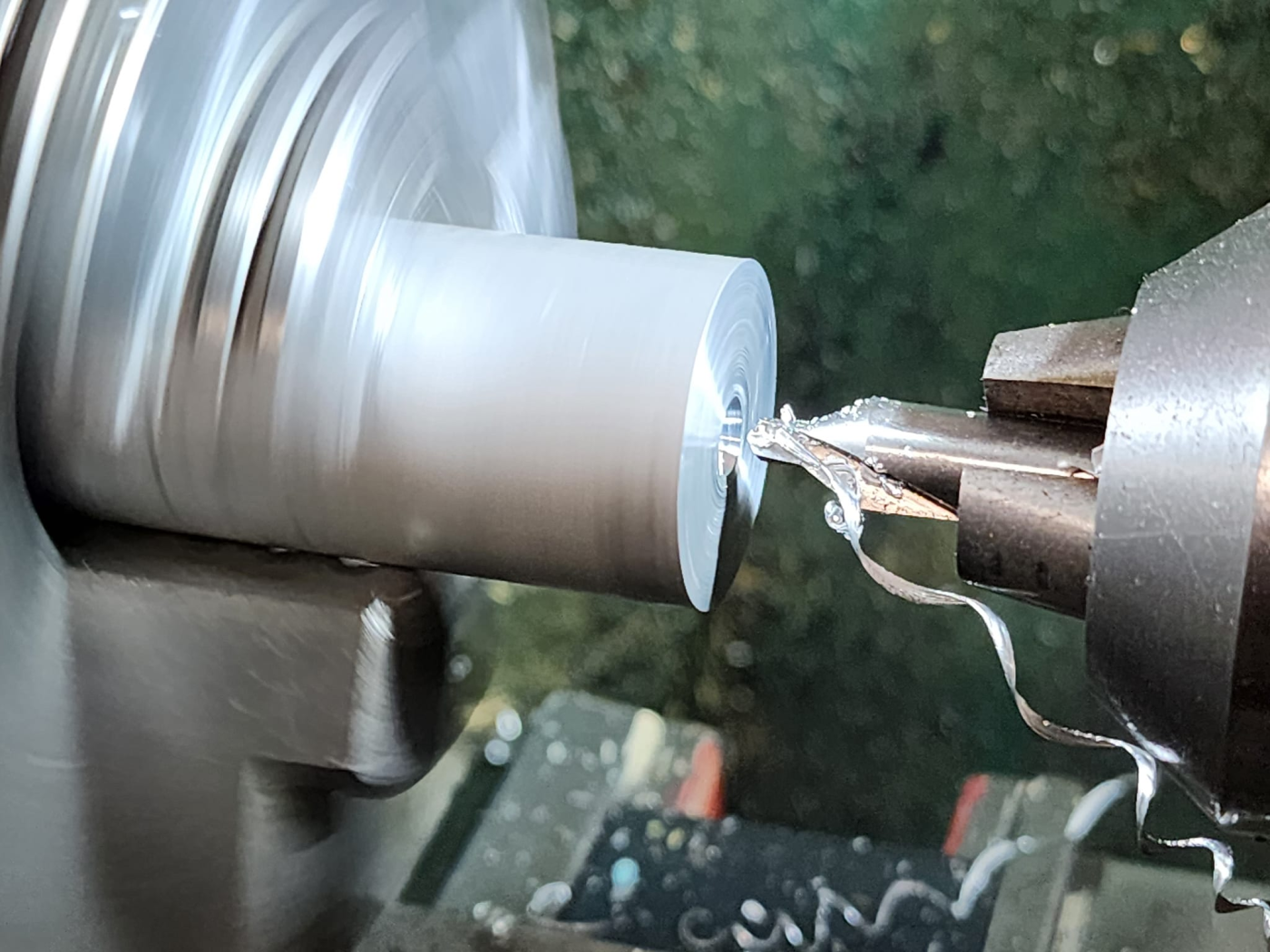

Then I faced off one end of each bar in the lathe.

I strained by brain for a bit, trying to figure out how to cut them to exactly the same length. I broke my V-block clamps, and haven't made a new set yet, so I got creative. I put an indicator in my Noga base and zeroed the machined side, then I milled off the end and zeroed my DRO there.

Put the next one in to the 0 mark, machined on the 0 mark, and they were only 0.0012 different in length. I could have done better, but for this use, that was pretty good!

Then I center drilled

Drilled with letter drill I

Tapped

Assembled, et voila! This ain't going nowhere! I could have done fancier, more machinistier things with precisely mating hooptums and snugly fitting blibble blabbles, but this simple design was easy to make and extremely robust.

So I fixed that problem once and for all today, and it was all "free" in that I just used stuff I already paid for long ago, and had in stock in my shop.

First, I cut a couple pieces of aluminum round bar to length.

Then I faced off one end of each bar in the lathe.

I strained by brain for a bit, trying to figure out how to cut them to exactly the same length. I broke my V-block clamps, and haven't made a new set yet, so I got creative. I put an indicator in my Noga base and zeroed the machined side, then I milled off the end and zeroed my DRO there.

Put the next one in to the 0 mark, machined on the 0 mark, and they were only 0.0012 different in length. I could have done better, but for this use, that was pretty good!

Then I center drilled

Drilled with letter drill I

Tapped

Assembled, et voila! This ain't going nowhere! I could have done fancier, more machinistier things with precisely mating hooptums and snugly fitting blibble blabbles, but this simple design was easy to make and extremely robust.

Last edited: