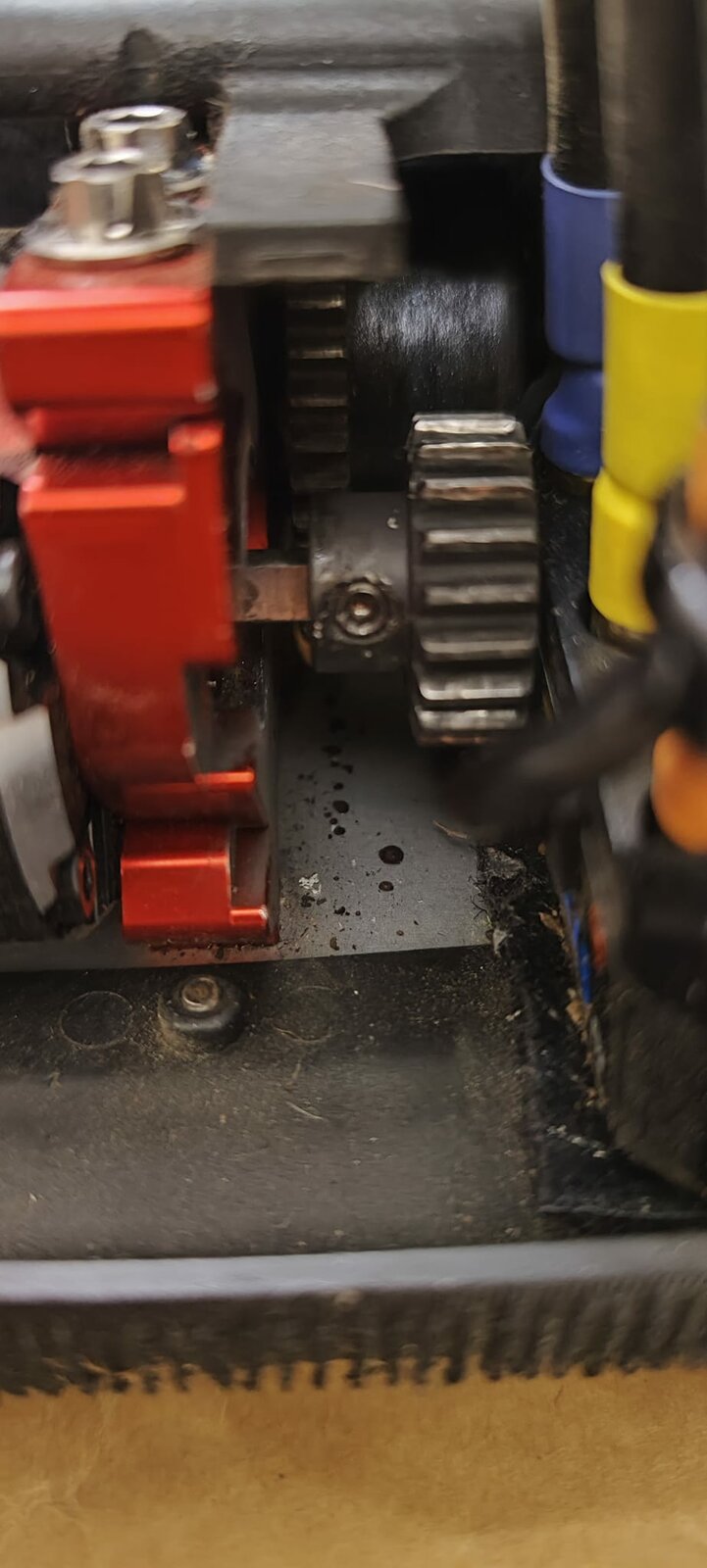

Just ran K6S max 6 1650kv G2 and pinion (20T) came loose with light use (grub/set screw was still quite tightly screwed in the pinion but the grub/set screw itself (which came with the pinion) seems to have worn with light use)

Any solutions?

Stronger Grub screw, D shaped Pinion, Pinion with 2 grub/set screws, 8MM To 5MM Pinion Reducer Sleeve?

Also does the HW max 6 (G2) esc fan only turn on at a certain temp?

Any solutions?

Stronger Grub screw, D shaped Pinion, Pinion with 2 grub/set screws, 8MM To 5MM Pinion Reducer Sleeve?

Also does the HW max 6 (G2) esc fan only turn on at a certain temp?