Matschik2023

Fairly New Member

- Messages

- 53

- Reaction score

- 34

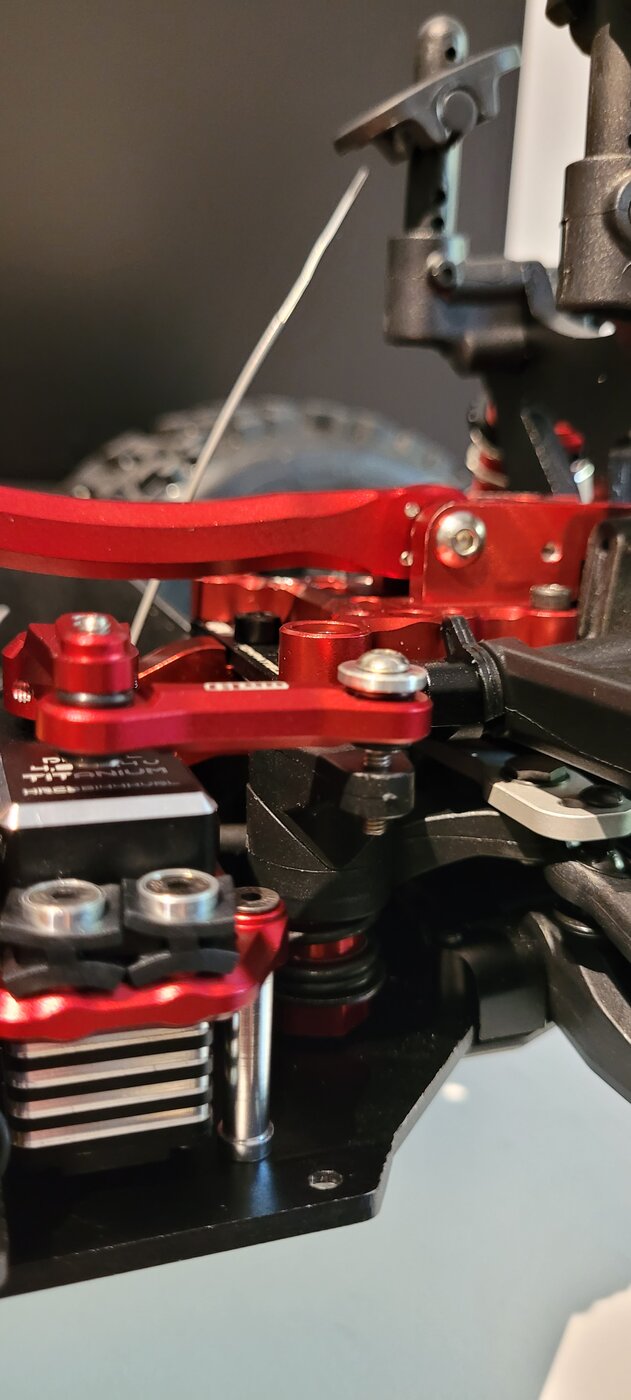

Hello, I hope somebody can help me? I am in the process of installing a new servo, servo mount and servo horn. As you can hopefully see in the picture, the distance between the steering lever and the steering linkage is too large. Does anyone have an idea what this could be or is there a solution for it?

Greetings Martin

Greetings Martin