Greengaunja

Ise da by' dat burns da Senton........

Premium Member

ArrmaForum Fan

Build Thread Contributor

- Messages

- 2,660

- Reaction score

- 4,518

- Location

- Durham Region, Ontario Canuckistan

- Arrma RC's

- Senton 6s

- Senton 3s

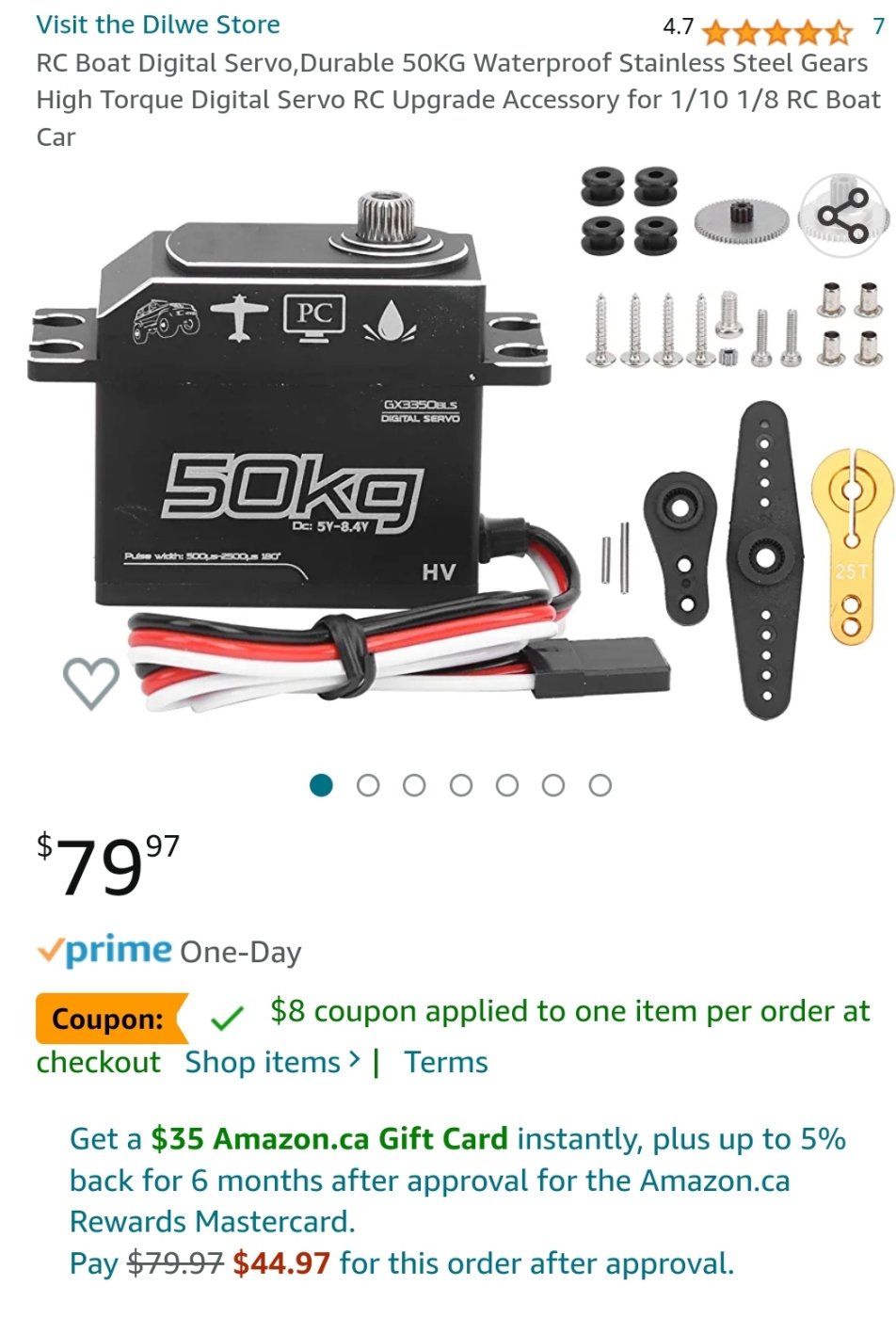

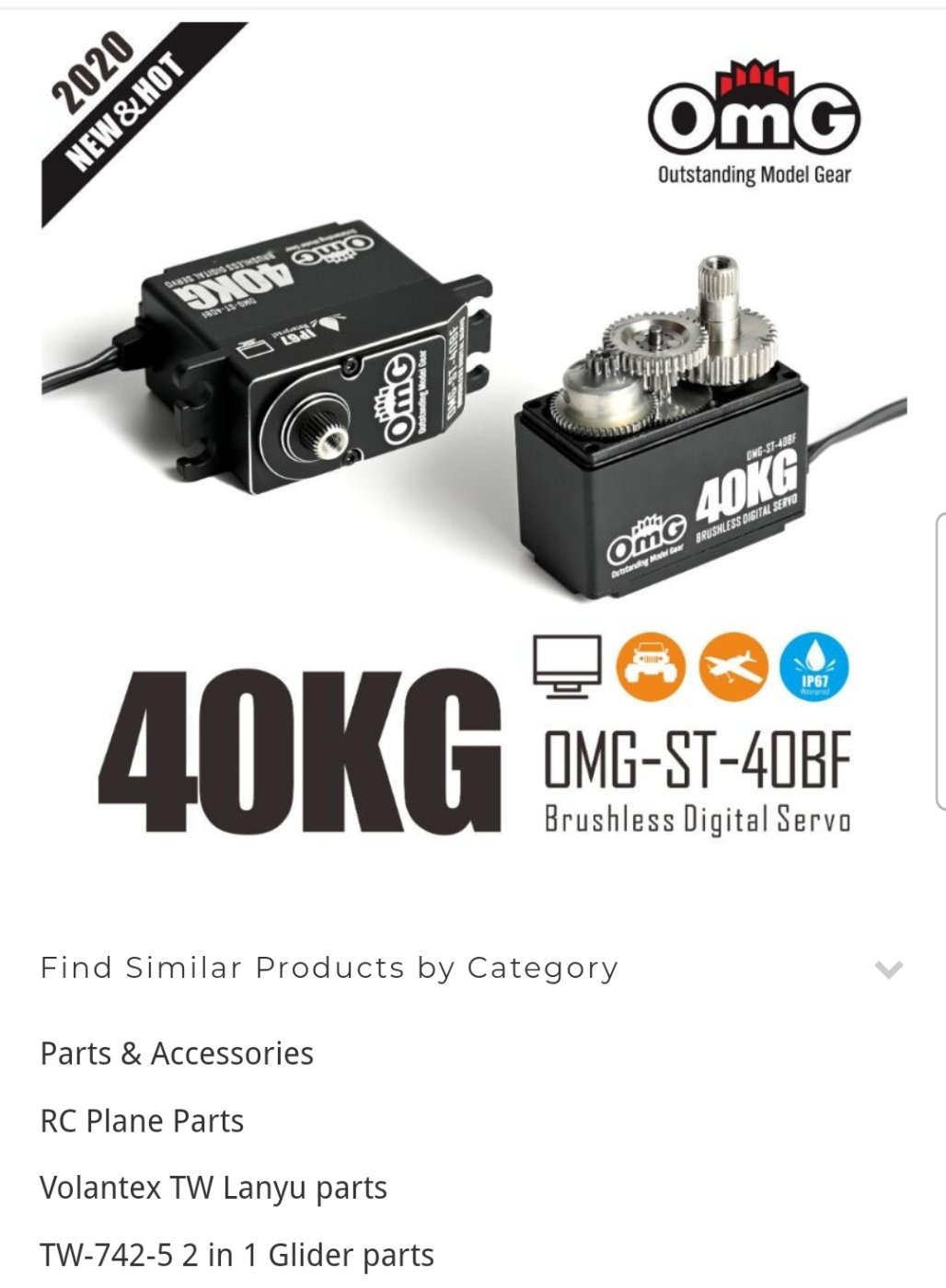

With my motor landing on the 16th and foams in Wednesday/Thursday, my speed build is finally coming to an end. The last 3 days have been spent looking into servos. I know I don't need high speeds or high torque(40kg is plently) I have been wondering which servo to use. It makes sense where others here say its stupid to rely on Amazon cheapies in an RC heavily invested into. I know mine will clear $2k easily so I want to offer it an added layer of protection/security. Having a cheapie fail mid run would suck. The one quality needed that fellow speed runners state is "centers and holds center well" has been my objective. Locally, the 40kg OMG has been suggested.

I just came back from my LHS where again the above servo was suggested.

I just came back from my LHS where again the above servo was suggested.

It's $130 so just slightly above what I budgeted for a servo. I have no idea if this is generic or if generics are based on this but Amazon and AliExpress has a bunch of very similar looking ones $50-70 cheaper.

The main nerd/tech guy at my LHS won't be back in until Monday and no one there today could really answer these next questions, so I'm hitting you guys up for some.

The main nerd/tech guy at my LHS won't be back in until Monday and no one there today could really answer these next questions, so I'm hitting you guys up for some.

When it comes to specs, I get and understand the voltages, speeds, and torque. But this next group is Chinese to me. I assume neutral position is the centering aspect, but the next value and Russian looking word has me lost. And which one would show its "holding center" capability? Can anyone give a Cliff Notes on this and what kind of values I should be looking for? Thanks in advance and it might be a good idea to pin something to our electronics section. If already there, it's not coming up in searches.

When it comes to specs, I get and understand the voltages, speeds, and torque. But this next group is Chinese to me. I assume neutral position is the centering aspect, but the next value and Russian looking word has me lost. And which one would show its "holding center" capability? Can anyone give a Cliff Notes on this and what kind of values I should be looking for? Thanks in advance and it might be a good idea to pin something to our electronics section. If already there, it's not coming up in searches.

It's $130 so just slightly above what I budgeted for a servo. I have no idea if this is generic or if generics are based on this but Amazon and AliExpress has a bunch of very similar looking ones $50-70 cheaper.