Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kraton Shrink wrapped motor connectors/placement

- Thread starter studmoney

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

Camaroboy383

Invention is the mother of necessity!

Premium Member

ArrmaForum Fan

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 5,104

- Reaction score

- 9,301

- Location

- Connecticut

- Arrma RC's

- 4x4-Mega

- Felony

- Outcast 4s

- Outcast 6s

- Outcast 8s

- Typhon 3s

- Typhon 6s

Heat shrink on the motor wires is where it's at.. .. no more disconnect after landing hard time after time..

.. no more disconnect after landing hard time after time..

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,881

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

Verticle or Flat as feasible on your specific rig. Generally it is best to keep wires secure enough so they don't flop around when bashing hard. That is how the solder joints weaken over time, then break. Wire ties and Heatshrink is always the way to go. Motor leads usually come apart at some point.

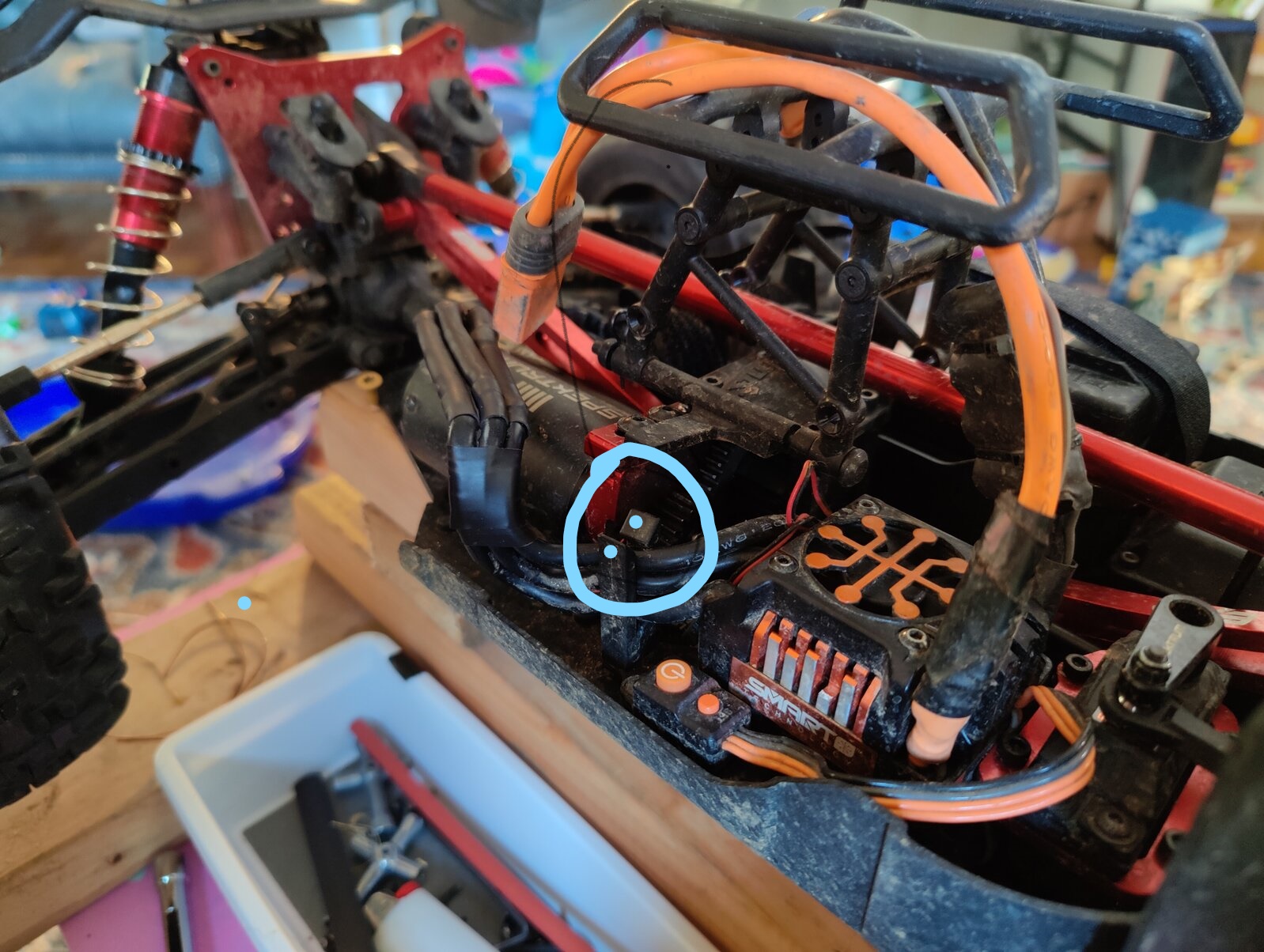

Below, I always drill a hole at the 2 blue dots and place a wire tie through it to keep the 3 wires in place.. The motor wires usually pop out here if you don't.

Below, I always drill a hole at the 2 blue dots and place a wire tie through it to keep the 3 wires in place.. The motor wires usually pop out here if you don't.

- Messages

- 584

- Reaction score

- 768

- Location

- from a galaxy far far away

- Arrma RC's

- Infraction

- Kraton EXB

- Talion

- Typhon 6s

- Typhon 3s

I always enjoy your replies, you always have some worthwhileVerticle or Flat as feasible on your specific rig. Generally it is best to keep wires secure enough so they don't flop around when bashing hard. That is how the solder joints weaken over time, then break. Wire ties and Heatshrink is always the way to go. Motor leads usually come apart at some point.

Below, I always drill a hole at the 2 blue dots and place a wire tie through it to keep the 3 wires in place.. The motor wires usually pop out here if you don't.

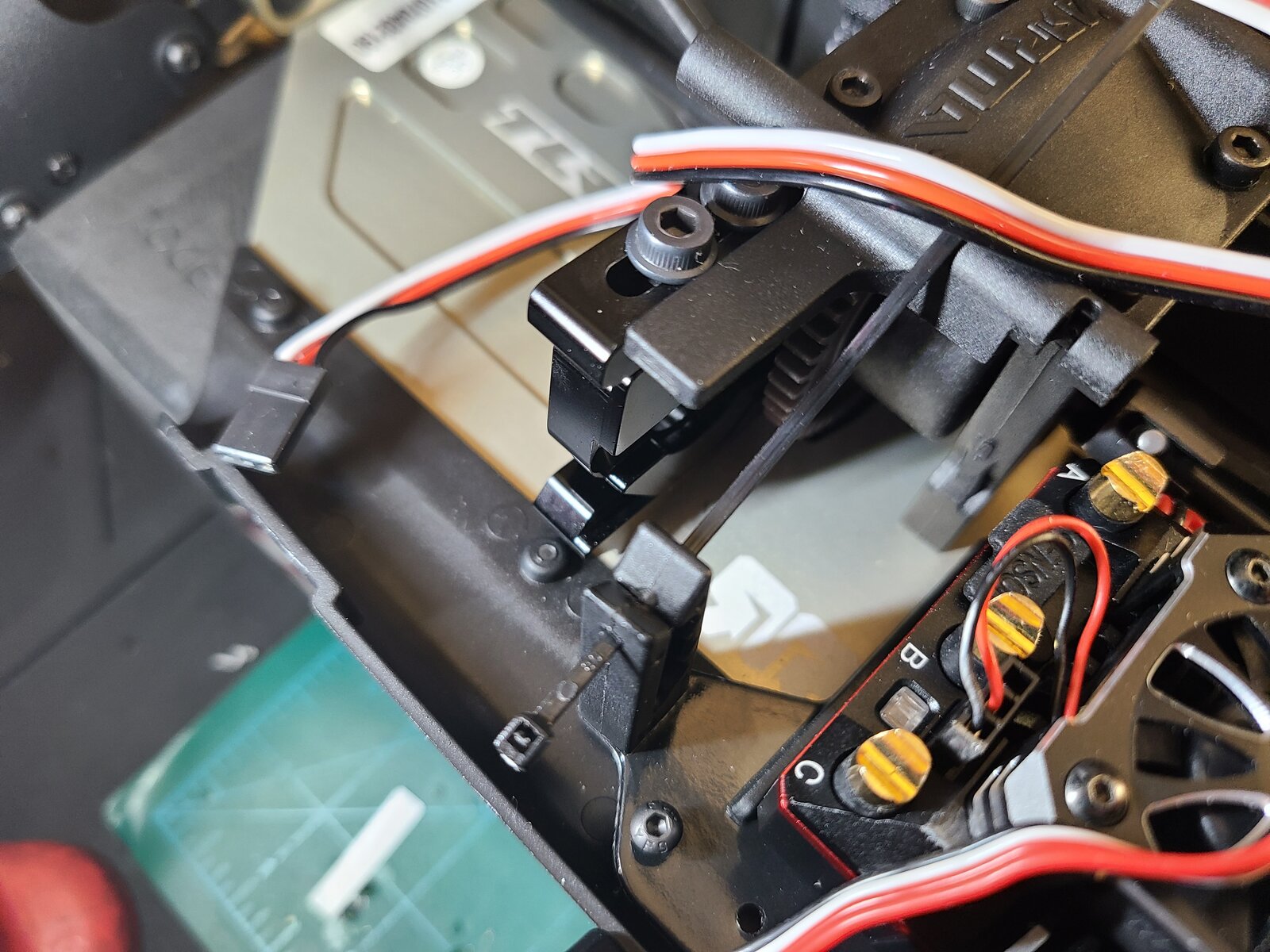

View attachment 184907

View attachment 184909

- Thread starter

- #5

That's awesome, thanksVerticle or Flat as feasible on your specific rig. Generally it is best to keep wires secure enough so they don't flop around when bashing hard. That is how the solder joints weaken over time, then break. Wire ties and Heatshrink is always the way to go. Motor leads usually come apart at some point.

Below, I always drill a hole at the 2 blue dots and place a wire tie through it to keep the 3 wires in place.. The motor wires usually pop out here if you don't.

View attachment 184907

View attachment 184909

Goodfast08

Active Member

Stealing the heat shrink on wires idea. Thanks!

- Thread starter

- #7

For sure, I had electrical tape on em and the still popped free after today's session so heat resistant shrink tube is clutch!!Stealing the heat shrink on wires idea. Thanks!

jondilly1974

Speed running apprentice, motor Slayer 🤘

Lifetime Premium!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 26,134

- Reaction score

- 38,839

- Location

- Toledo, OH

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Kraton EXB

- Senton 3s

- Typhon 6s

- Typhon 3s

Get the marine type with adhesive if you canFor sure, I had electrical tape on em and the still popped free after today's session so heat resistant shrink tube is clutch!!

Livesalty710

Fairly New Member

- Messages

- 31

- Reaction score

- 20

- Arrma RC's

- Senton 3s

What size?Get the marine type with adhesive if you can

Livesalty710

Fairly New Member

- Messages

- 31

- Reaction score

- 20

- Arrma RC's

- Senton 3s

What size?First bash session with the shrink wrapped wires and the heat from the motor only solidified the wrap further very cool idea.