I found a nero for 200 cad and decided to jump on it. Its the non diff brain version and has weaker axles vs the nero big rock. Planning on doing the screw mod to seal the diffs to run oil. Because running as is is not going to be very great. The guy sprayed grease everywhere. Even when run trough water and cleaned and dried stuff going to rust. Hinge pins one had like mushroom rust i had to send down and ton of force to get it out my ultrasonic is great at cleaning light grease but heavy grease its a bit of a nightmare. Found rust inside the radiobox and a tiny bit of corrosion on one of the receiver pins. The esc switch has rust inside? Theres some brown through the clear silicone. Motor had ton of rust dust and rust on the stator but i sont think that will effect its running

One annoyance of the nero vs the big rock. To remove the rear of the vehicle i had to remove the whole side panel off because the body post mount is keyed into the chassis i though i could just pull it up and it would come out but it didnt.

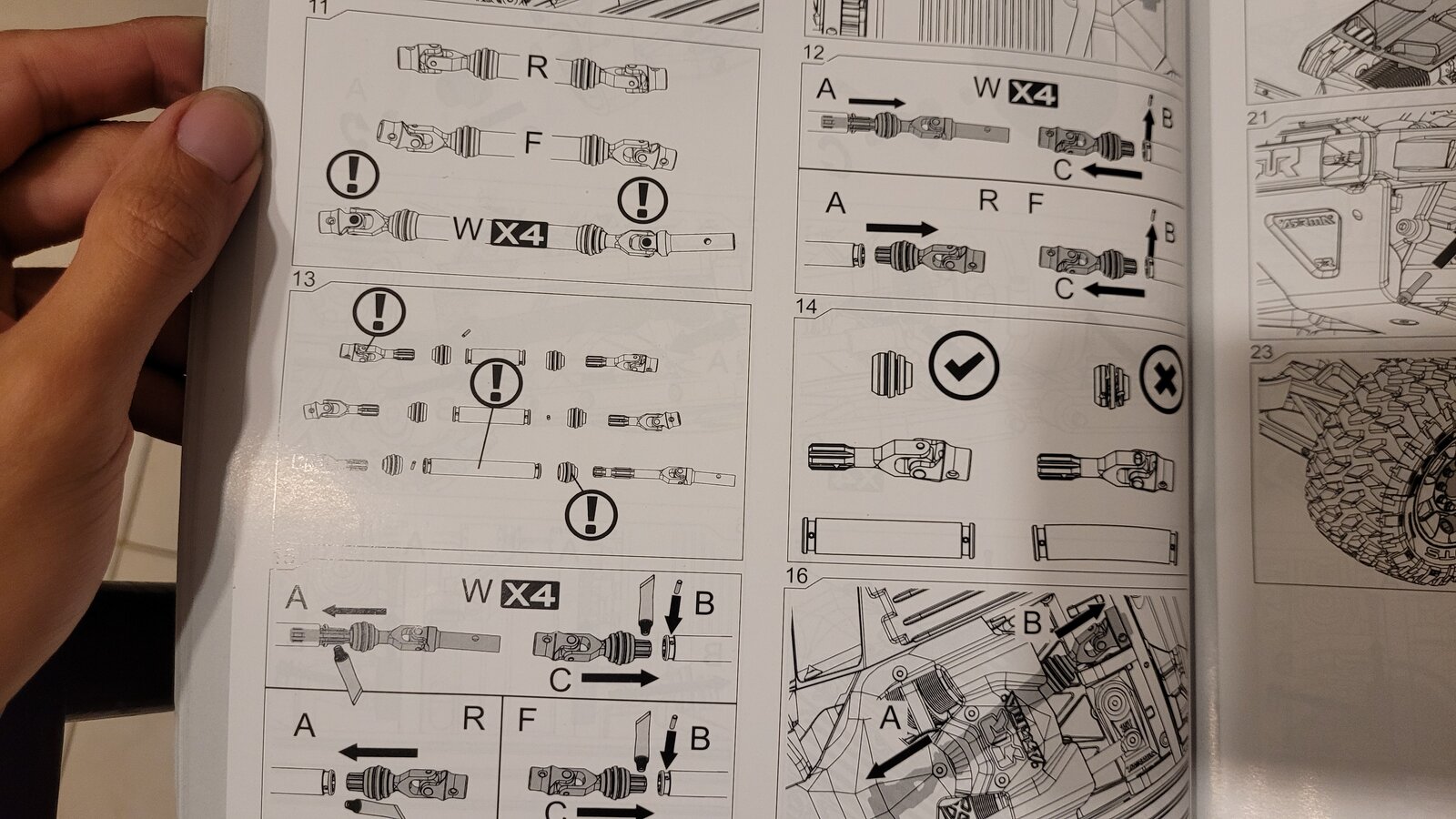

I had to order a wheelie bar, new diff gaskets, orings and rear, somerhing important i learned is the axles MUST BE in sync. In the nero you can put the axles any way you want. They have to be iligned. On my bigrock i didnt know this and i had vibrations and up and it felt like my motor was breaking itself in neutral and under heavy throttle. After i fixed that it calmed quite a lot. I have 3d printed mud guards ready. Those are a must as you can see..

By the looks of it he broke 3 of the 4 eod ends on the shocks. Changed the spring to the optional 75mm ones who are less hard. Im not going to do much shock wise. Went crazy with the bigrock with fiteteam springs i mainly did it because of the insane ground clearence i gained once modified and i wanted to be able to crawl. I need to design ne spring perches, i don't want to grind the rods ends to fit the ones i previously made. The point of it is to avoid twisting the shock ends and bending the shafts i will lose the ability to adjust the rid height if i do tho

Currently changing the shock rods on two of the shocks for nero HD. im going to have to use a plastic 3s pivot ball because one is missing

One annoyance of the nero vs the big rock. To remove the rear of the vehicle i had to remove the whole side panel off because the body post mount is keyed into the chassis i though i could just pull it up and it would come out but it didnt.

I had to order a wheelie bar, new diff gaskets, orings and rear, somerhing important i learned is the axles MUST BE in sync. In the nero you can put the axles any way you want. They have to be iligned. On my bigrock i didnt know this and i had vibrations and up and it felt like my motor was breaking itself in neutral and under heavy throttle. After i fixed that it calmed quite a lot. I have 3d printed mud guards ready. Those are a must as you can see..

By the looks of it he broke 3 of the 4 eod ends on the shocks. Changed the spring to the optional 75mm ones who are less hard. Im not going to do much shock wise. Went crazy with the bigrock with fiteteam springs i mainly did it because of the insane ground clearence i gained once modified and i wanted to be able to crawl. I need to design ne spring perches, i don't want to grind the rods ends to fit the ones i previously made. The point of it is to avoid twisting the shock ends and bending the shafts i will lose the ability to adjust the rid height if i do tho

Currently changing the shock rods on two of the shocks for nero HD. im going to have to use a plastic 3s pivot ball because one is missing

Last edited: