Barmaleus

Active Member

Hey all!

While double checking measurements of hinge pin mounts (https://www.arrmaforum.com/threads/ok-if-something-happens-to-these-i-am-done.70093/), I was astonished. Really.

The pins that go into the mounts (both front and rear) are 4mm (https://www.horizonhobby.de/en_DE/product/hinge-pin-lower-4x63.5mm-2/ARA330731.html).

One would expect the mount holes to be sliiiighly bigger for a tight fit. After all, this is a critical part of the car that holds together a lot of important stuff.

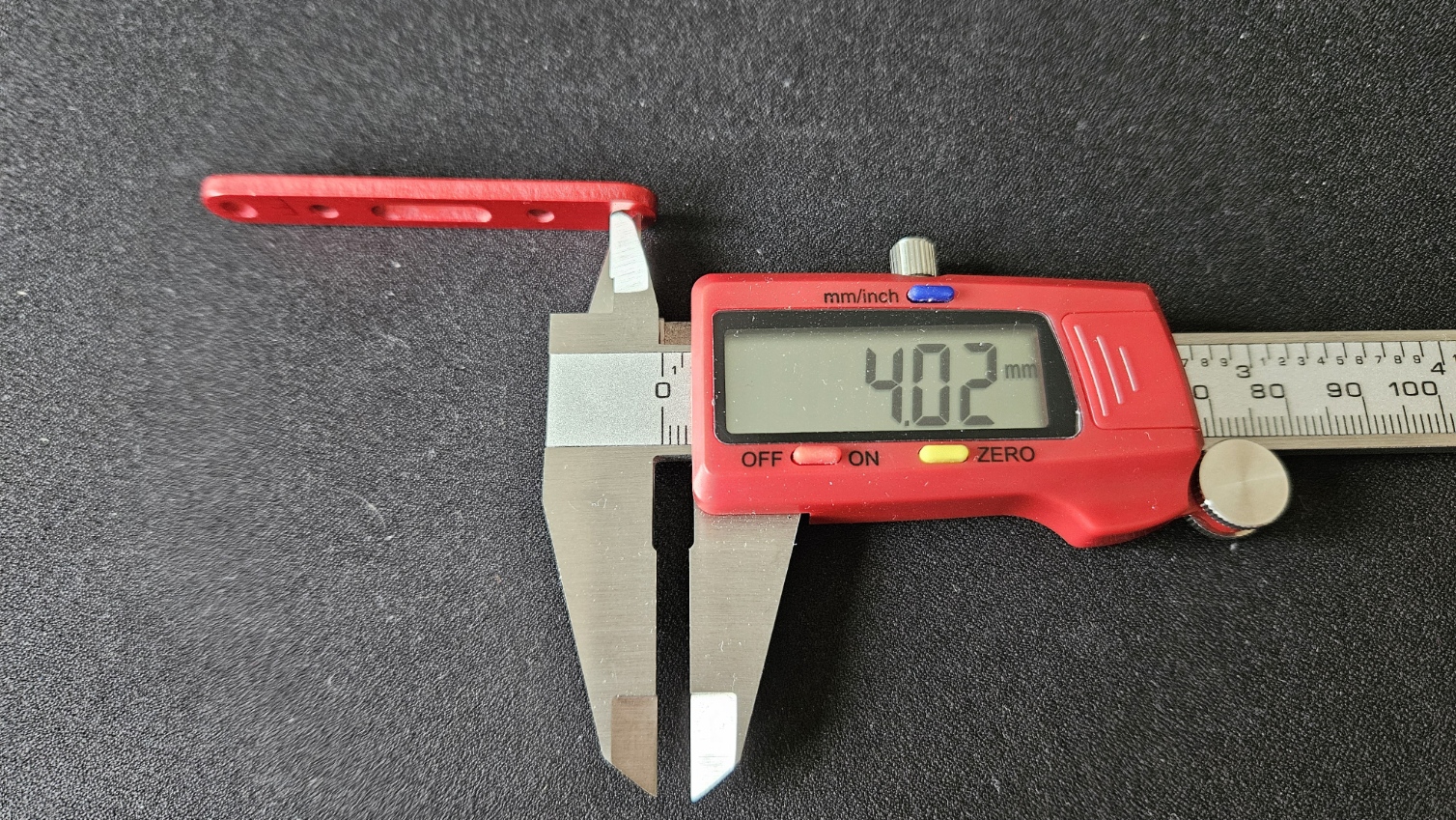

The front mount: 4.02mm and 4.01mm. Looks absolutely reasonable.

The rear mount? 4.36mm and 4.40mm. The holes are 9-10% larger than they should be.

So I am wondering, am I too picky? Do you think such part tolerances should be acceptable?

While double checking measurements of hinge pin mounts (https://www.arrmaforum.com/threads/ok-if-something-happens-to-these-i-am-done.70093/), I was astonished. Really.

The pins that go into the mounts (both front and rear) are 4mm (https://www.horizonhobby.de/en_DE/product/hinge-pin-lower-4x63.5mm-2/ARA330731.html).

One would expect the mount holes to be sliiiighly bigger for a tight fit. After all, this is a critical part of the car that holds together a lot of important stuff.

The front mount: 4.02mm and 4.01mm. Looks absolutely reasonable.

The rear mount? 4.36mm and 4.40mm. The holes are 9-10% larger than they should be.

So I am wondering, am I too picky? Do you think such part tolerances should be acceptable?