Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Big Rock Here we go! 😂

- Thread starter kaladeth

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

- Messages

- 1,055

- Reaction score

- 2,887

- Location

- MN

- Arrma RC's

- BigRock 4x4

- Granite

- Granite Grom

- Granite Mega

- Kraton 6s

- Typhon 3s

- Typhon Mega

This should be good. I give it about 5 minutes. Lol.

MrTitanium

Speak softly and carry a big stick.

- Messages

- 2,848

- Reaction score

- 14,980

- Arrma RC's

- BigRock

- BigRock 4x4

- Granite Grom

- Kraton EXB

- Nero

- Infraction 4x4

Your diffs are gonna need psychological therapy cause they’ll have no idea wtf hit them.

- Messages

- 1,055

- Reaction score

- 2,887

- Location

- MN

- Arrma RC's

- BigRock 4x4

- Granite

- Granite Grom

- Granite Mega

- Kraton 6s

- Typhon 3s

- Typhon Mega

Unless he shoe horns in the new 4S center diff. Then I give it 10 minutes.Your diffs are gonna need psychological therapy cause they’ll have no idea wtf hit them.

MrTitanium

Speak softly and carry a big stick.

- Messages

- 2,848

- Reaction score

- 14,980

- Arrma RC's

- BigRock

- BigRock 4x4

- Granite Grom

- Kraton EXB

- Nero

- Infraction 4x4

It’s the 3s. The Nero BR has the shocks in the horizontal position and wouldn’t be visible from that photo angle.I can't tell if this is a BR 3S or a Nero BR...

- Messages

- 401

- Reaction score

- 717

- Location

- East Bay, CA

- Arrma RC's

- Granite

- Kraton 6s

- Typhon TLR

- Infraction 4x4

Do you have metal diffs in there? If not, you're gonna need em. I got max 10 and 3674 in mine rn +center diff conv.. 3s is fine. 4s ran for about 2 packs then started hearing grinding. Opened up diffs and nothing but polymer powder in there

NitroK

Active Member

- Messages

- 289

- Reaction score

- 958

- Arrma RC's

- BigRock 4x4

- Kraton 6s

No truer words to express the pending carnage.Your diffs are gonna need psychological therapy cause they’ll have no idea wtf hit them.

I only upgraded the motor on my BRCC 3s and all kinds of stuff started falling apart. Kaladeth, please let us know how it turns out.

- Messages

- 6,655

- Reaction score

- 11,300

- Location

- Rhode island

- Arrma RC's

- BigRock 4x4

- Kraton 6s

- Outcast 6s

- Vendetta

- Infraction 4x4

Shocks are uprightI can't tell if this is a BR 3S or a Nero BR...

Barmaleus

Active Member

I don't know what's going on, but I like it.

- Thread starter

- #13

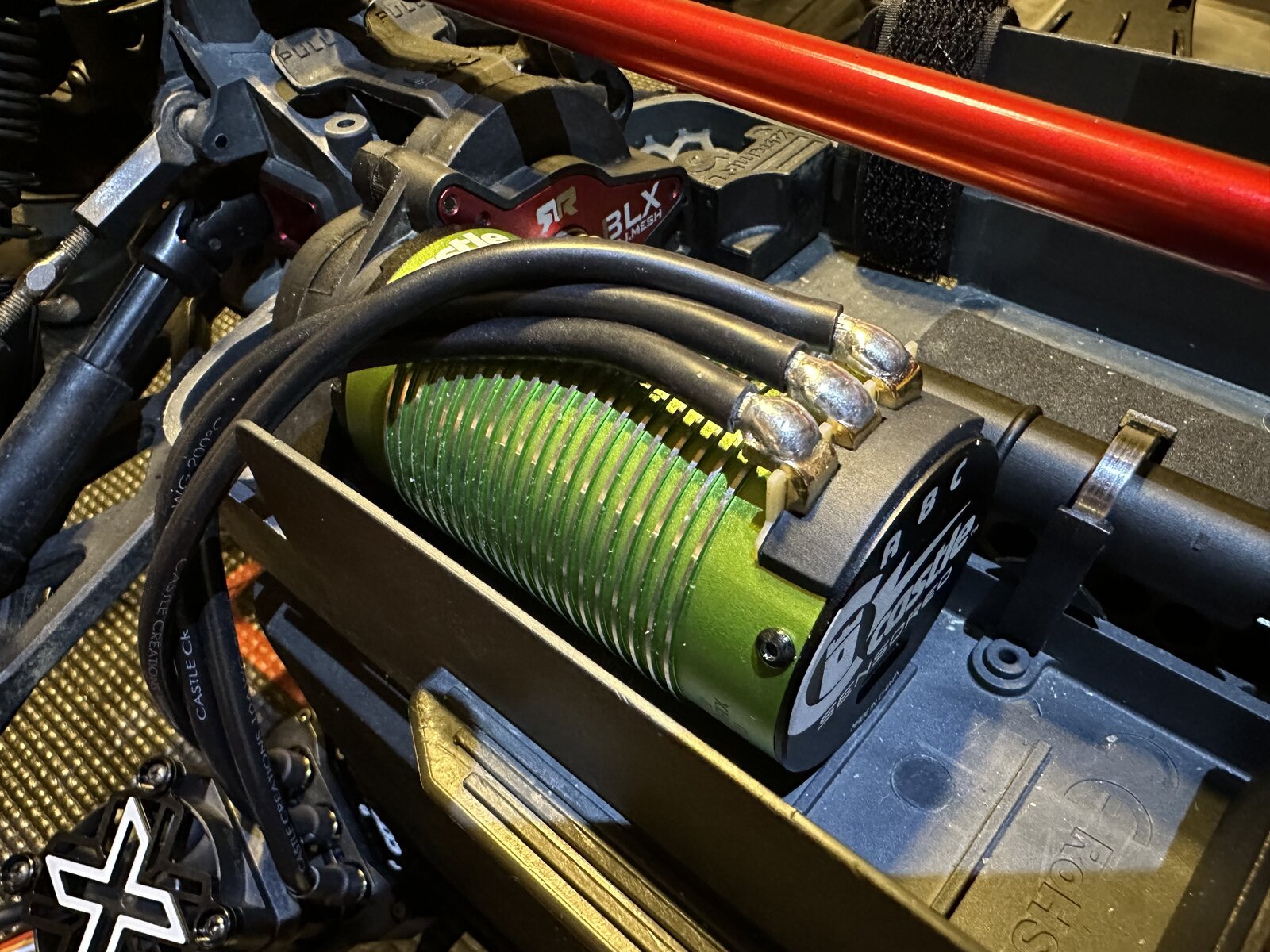

Road Block #1

The 1717 seems to be too big although I have heard others were able to just drop one in (eg. into a Vendetta).

This is a Big Rock V3 3S BLX with the stock motor mount plate and case ARA311032.

The motor, when mounted, has a big enough diameter (47 mm with fins) that ends up lifting the motor casing off the chassis (by about 3mm), preventing the mount from sliding and slotting into the back clips.

I took off the front case to have a better look. For the drive shaft hole to stay aligned with the center line, the mount plate needs to twist ~4 degrees counterclockwise to accommodate the motor. (Left side 3mm down, right side 3mm up)

If not, from this pic you can see the motor shaft needs to go about 3mm lower in order to be vertically centered in the mount to fit the mounting holes.

It seems like I need a different mount or make my own custom mount case.

I can also just switch to a stock big rock 6S esc and motor and call it a day, but wanted to explore all options first.

Any thoughts or ideas?

The 1717 seems to be too big although I have heard others were able to just drop one in (eg. into a Vendetta).

This is a Big Rock V3 3S BLX with the stock motor mount plate and case ARA311032.

The motor, when mounted, has a big enough diameter (47 mm with fins) that ends up lifting the motor casing off the chassis (by about 3mm), preventing the mount from sliding and slotting into the back clips.

I took off the front case to have a better look. For the drive shaft hole to stay aligned with the center line, the mount plate needs to twist ~4 degrees counterclockwise to accommodate the motor. (Left side 3mm down, right side 3mm up)

If not, from this pic you can see the motor shaft needs to go about 3mm lower in order to be vertically centered in the mount to fit the mounting holes.

It seems like I need a different mount or make my own custom mount case.

I can also just switch to a stock big rock 6S esc and motor and call it a day, but wanted to explore all options first.

Any thoughts or ideas?

Last edited:

- Thread starter

- #15

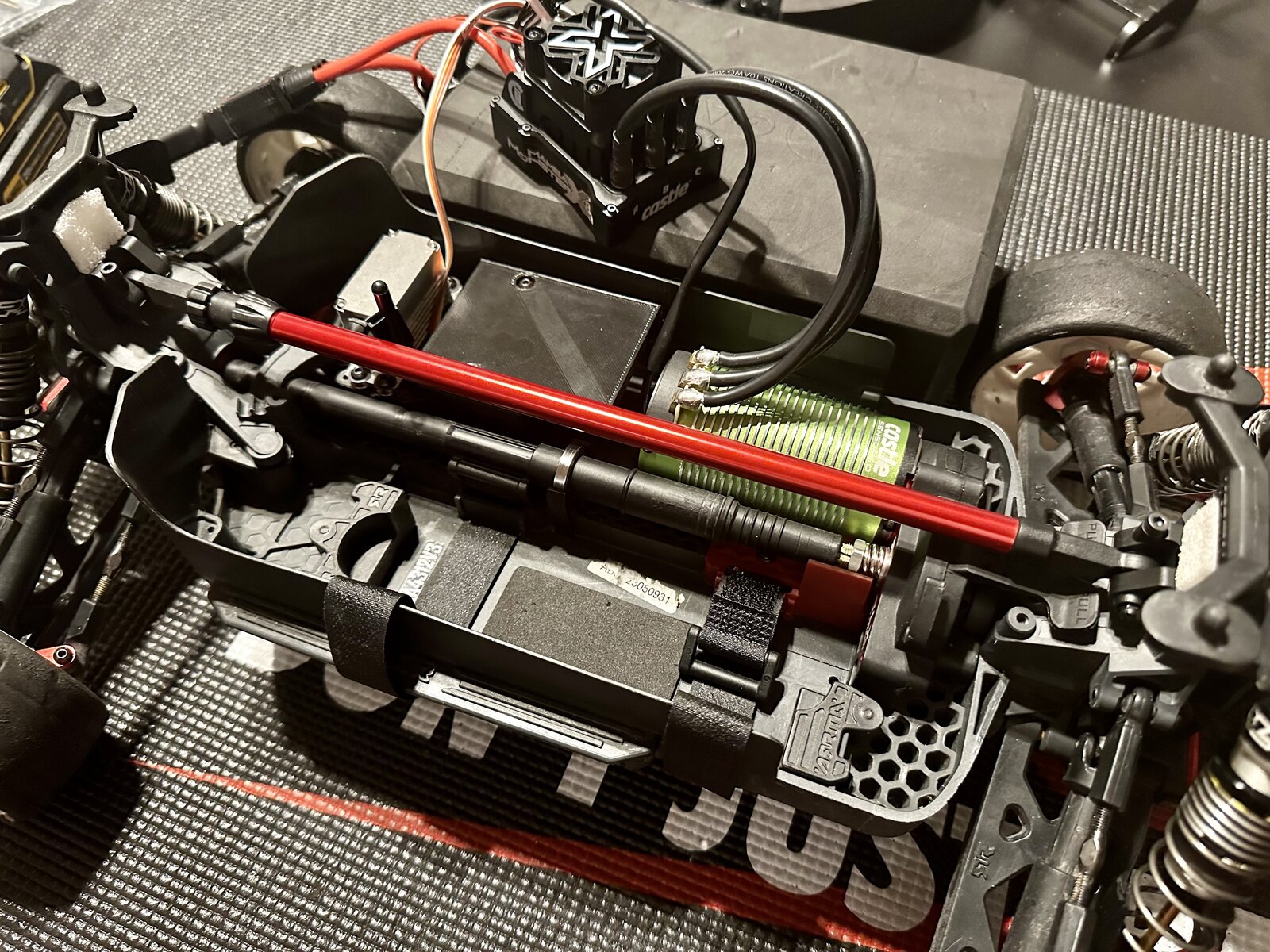

Got it in there. This is literally pushing it:

Road Block #2

I’m going to need a bigger pinion to move the motor further away from the drive shaft (17t to 20t or 21t). Or get a thinner drive shaft. Yes I ran the motor and yes those are groves on the plastic driveshaft made by the fins on the motor.

Road Block #2

I’m going to need a bigger pinion to move the motor further away from the drive shaft (17t to 20t or 21t). Or get a thinner drive shaft. Yes I ran the motor and yes those are groves on the plastic driveshaft made by the fins on the motor.

NitroK

Active Member

- Messages

- 289

- Reaction score

- 958

- Arrma RC's

- BigRock 4x4

- Kraton 6s

Looks so pretty. On a positive note, you have eliminated two of the main problems with the Big Rock;

1) Gap between stock motor and chassis which results in bent motor mount on hard impact

2) Pebbles getting into the space between center drive shaft and motor, resulting in premature wear of drive shaft.

1) Gap between stock motor and chassis which results in bent motor mount on hard impact

2) Pebbles getting into the space between center drive shaft and motor, resulting in premature wear of drive shaft.

- Thread starter

- #17

Test fitting with a 3D printed gear, the 21T looks good. I would say the minimum is a 20T and the maximum is a 22T.

- Thread starter

- #18

Pinion set. Ready to mount the ESC!

Poor driveshafts

Similar threads

- Replies

- 8

- Views

- 690