I open this thread to talk about all my Arrma cars.

Big Rock Crew cab

Unboxing :

Speed test + bashing :

First test of new ramp :

Upgrades :

- T-bone front bumper : https://tboneracing.net/collections/bigrock-3s/products/10095-tbr-xv6-front-bumper-arrma-big-rock-3s

- GPM Racing front hub carrier : https://www.gpmracing.com.hk/en/pro...10-4WD-GRANITE-4X4-MEGA-MOSTER-TRUCK-AR102680

- Gpm Racing cvd (on front) : https://www.gpmracing.com.hk/en/pro...-10-4WD-BIG-ROCK-CREW-CAB-4X4-3S-BLX-AR102711

- Arrma Granite Wheels : https://www.arrma-rc.com/part/AR550045

- Cheap 25Kg steering servo.

The GPM racing drive shaft are quite hard to put in place, mainly the differential outdrive which is a very very very thigh fit. This is how i did :

- I removed the C-hub from the a-arm by removing the C-hub pin.

- I removed the front shock absorber to have enough room for working.

- I removed the stock CVD.

- I put the GPM "drive cup" on the differenital axle, just in front of the axle, by turning it we can feel the "spline shaft" are aligned.

- I took a 10mm with normal head screw, for 2.5mm hex driver. The screws provided by GPM are too short at this step.

- I put the screw in the hole in the gpm "drive cup" and hold the drive cup with a 1.5mm hex screw driver in the hole for the pin for avoiding the drive cup and diff. axle to turn..

- Then i screw the screw.

- I checked if the "drive cup" was well aligned by turning the opposite wheel, if it wasn't aligned, i hammered the drive cup a little bit to align it.

- I contiuned to screw, it will be hard to tight, i screwed it as far as i could do, this push the drive cup in place.

- When it was too hard to screw, i changed the screw for a 8mm one and repeat the same step above.

As i show at the end of the video the main damages are : a velcro strap broken and the plastic center axle shredded by a small pebble. It isn't that much when we see the bad landing it took. The surface is aslphat covered by dust, sand and gravel. After a closer look i also broke the small bar which held the front aluminum a-arm's hinge pin brace on the T-bone front bumper.

The car isn't so easy to handle on this kind of loose surface. When you hit the throttle too fast the rear end tend to drift on the side quickly. But the handling is better with wider tires. The motor/esc tend to cog sometime. The reverse doesn't respond quickly sometime also. There is still the problem of gravel/pebble which tend to bind the steering quite often. Two shock absorbers leak like crazy. But overall the car is fun to use and seems pretty solid with the upgrade.

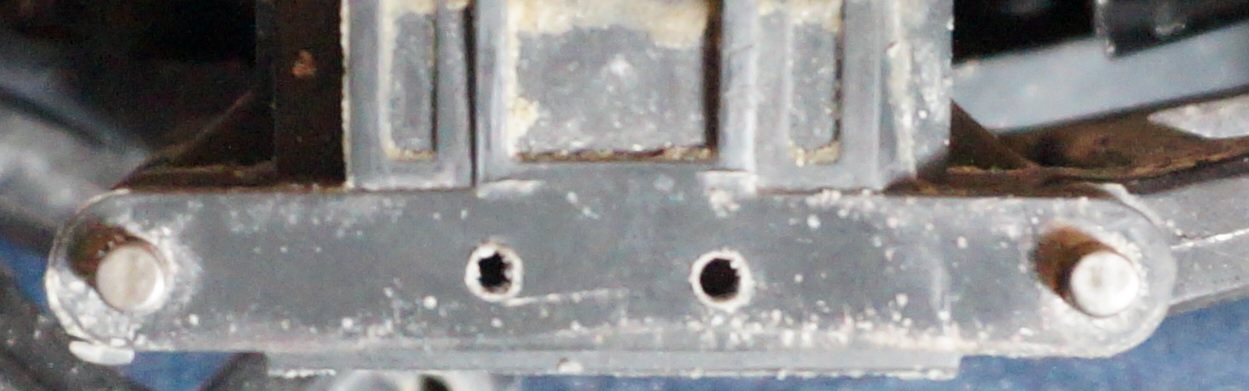

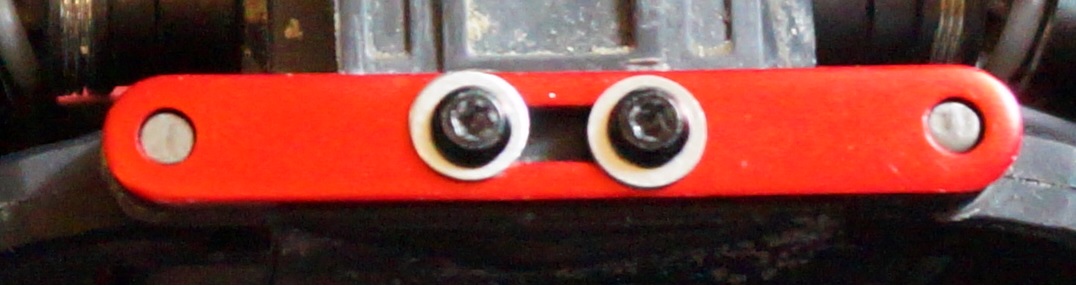

Front a-arms aluminum brace mod :

As i have broken the small plastic part which is on the T-bone front bumper, the one which hold the aluminum a-arms brace, i have lost the front aluminum a-arms brace. So i decided to do a quick modification to avoid to lost it again.

I did two holes with a 2.5mm drill tip. I threaded the holes with a M3 tap thread.

Arrma Kraton 6s BLX V2

Unboxing :

I know it isn't new, even old now, but it is my Kraton V2 and i love it ^^.

Speed test + bashing :

New bashing spot :

Upgrades :

So far not that much.

- Rear Voltage aluminum chassis brace : https://www.voltagehobbies.com/store/p28/Voltage_Hobbies_Rear_Chassis_Brace_for_ARRMA_Kraton,_Talion.html#/

- GPM aluminum servo mount : https://www.gpmracing.com.hk/en/pro...NSTER-TRUCK--ARA106040T1#sthash.8Co556Zl.dpbs

- GPM front skid plate : https://www.gpmracing.com.hk/en/pro...NSTER-TRUCK--ARA106040T1#sthash.iPN5ugPi.dpbs

- RPM rear skid plate : https://www.rpmrcproducts.com/shop/...or-arrma-durango-8th-and-10th-scale-vehicles/

- Markhor carbon fiber upper deck : https://www.ampedrc.com.au/product/markhor-rc-kraton-and-talion-carbon-fibre-top-deck/

Notorious 6s BLX 2019

First bash on 6s :

Upgrades :

- Front RPM bumper : https://www.rpmrcproducts.com/shop/...kid-plate-for-the-arrma-kraton-durango-dex8t/

- GPM rear skid plate : https://www.gpmracing.com.hk/en/pro...NSTER-TRUCK--ARA106040T1#sthash.WLG3uhVE.dpbs

- GPM steering servo mount : https://www.gpmracing.com.hk/en/pro...NSTER-TRUCK--ARA106040T1#sthash.8Co556Zl.dpbs

- Hot racing front chassis brace : https://hot-racing.com/?partnumber=AON28C01;c=1058

- Hot racing rear chassis brace : https://hot-racing.com/?partnumber=AON30X01;c=1058

- Banggood aluminum wheel nuts : https://fr.banggood.com/4PCS-17mm-Dust-Resistant-CNC-Nut-for-18-RC-Car-AGAMA-XRAY-LOSI-HB-AE-MUGEN-TEAM-C-HSP-ZD-p-1575655.html

- Tactic TTX300

Big Rock Crew cab

Unboxing :

Speed test + bashing :

First test of new ramp :

Upgrades :

- T-bone front bumper : https://tboneracing.net/collections/bigrock-3s/products/10095-tbr-xv6-front-bumper-arrma-big-rock-3s

- GPM Racing front hub carrier : https://www.gpmracing.com.hk/en/pro...10-4WD-GRANITE-4X4-MEGA-MOSTER-TRUCK-AR102680

- Gpm Racing cvd (on front) : https://www.gpmracing.com.hk/en/pro...-10-4WD-BIG-ROCK-CREW-CAB-4X4-3S-BLX-AR102711

- Arrma Granite Wheels : https://www.arrma-rc.com/part/AR550045

- Cheap 25Kg steering servo.

The GPM racing drive shaft are quite hard to put in place, mainly the differential outdrive which is a very very very thigh fit. This is how i did :

- I removed the C-hub from the a-arm by removing the C-hub pin.

- I removed the front shock absorber to have enough room for working.

- I removed the stock CVD.

- I put the GPM "drive cup" on the differenital axle, just in front of the axle, by turning it we can feel the "spline shaft" are aligned.

- I took a 10mm with normal head screw, for 2.5mm hex driver. The screws provided by GPM are too short at this step.

- I put the screw in the hole in the gpm "drive cup" and hold the drive cup with a 1.5mm hex screw driver in the hole for the pin for avoiding the drive cup and diff. axle to turn..

- Then i screw the screw.

- I checked if the "drive cup" was well aligned by turning the opposite wheel, if it wasn't aligned, i hammered the drive cup a little bit to align it.

- I contiuned to screw, it will be hard to tight, i screwed it as far as i could do, this push the drive cup in place.

- When it was too hard to screw, i changed the screw for a 8mm one and repeat the same step above.

As i show at the end of the video the main damages are : a velcro strap broken and the plastic center axle shredded by a small pebble. It isn't that much when we see the bad landing it took. The surface is aslphat covered by dust, sand and gravel. After a closer look i also broke the small bar which held the front aluminum a-arm's hinge pin brace on the T-bone front bumper.

The car isn't so easy to handle on this kind of loose surface. When you hit the throttle too fast the rear end tend to drift on the side quickly. But the handling is better with wider tires. The motor/esc tend to cog sometime. The reverse doesn't respond quickly sometime also. There is still the problem of gravel/pebble which tend to bind the steering quite often. Two shock absorbers leak like crazy. But overall the car is fun to use and seems pretty solid with the upgrade.

Front a-arms aluminum brace mod :

As i have broken the small plastic part which is on the T-bone front bumper, the one which hold the aluminum a-arms brace, i have lost the front aluminum a-arms brace. So i decided to do a quick modification to avoid to lost it again.

I did two holes with a 2.5mm drill tip. I threaded the holes with a M3 tap thread.

Arrma Kraton 6s BLX V2

Unboxing :

Speed test + bashing :

New bashing spot :

Upgrades :

So far not that much.

- Rear Voltage aluminum chassis brace : https://www.voltagehobbies.com/store/p28/Voltage_Hobbies_Rear_Chassis_Brace_for_ARRMA_Kraton,_Talion.html#/

- GPM aluminum servo mount : https://www.gpmracing.com.hk/en/pro...NSTER-TRUCK--ARA106040T1#sthash.8Co556Zl.dpbs

- GPM front skid plate : https://www.gpmracing.com.hk/en/pro...NSTER-TRUCK--ARA106040T1#sthash.iPN5ugPi.dpbs

- RPM rear skid plate : https://www.rpmrcproducts.com/shop/...or-arrma-durango-8th-and-10th-scale-vehicles/

- Markhor carbon fiber upper deck : https://www.ampedrc.com.au/product/markhor-rc-kraton-and-talion-carbon-fibre-top-deck/

Notorious 6s BLX 2019

First bash on 6s :

Upgrades :

- Front RPM bumper : https://www.rpmrcproducts.com/shop/...kid-plate-for-the-arrma-kraton-durango-dex8t/

- GPM rear skid plate : https://www.gpmracing.com.hk/en/pro...NSTER-TRUCK--ARA106040T1#sthash.WLG3uhVE.dpbs

- GPM steering servo mount : https://www.gpmracing.com.hk/en/pro...NSTER-TRUCK--ARA106040T1#sthash.8Co556Zl.dpbs

- Hot racing front chassis brace : https://hot-racing.com/?partnumber=AON28C01;c=1058

- Hot racing rear chassis brace : https://hot-racing.com/?partnumber=AON30X01;c=1058

- Banggood aluminum wheel nuts : https://fr.banggood.com/4PCS-17mm-Dust-Resistant-CNC-Nut-for-18-RC-Car-AGAMA-XRAY-LOSI-HB-AE-MUGEN-TEAM-C-HSP-ZD-p-1575655.html

- Tactic TTX300

Last edited: