It all started when I put peg board in my ‘shop over the summer. Having quick access to my tools really upped the enjoyment of RC, especially the wrenching part. Something I always wanted to do to my Kraton since I got it in 2020 was to put a huge motor in it. Now that the kids are a little older, I have some time, and barely enough available funds to justify this, here is the project so far. Santa is bringing the HW56118 for Christmas along with some Saga gears to complete the set up. Hopefully the majority of the hard work is done, but we will see.

The beginnings of a make shift peg board. I did this with 1x1 boards and screws for Hardie backer board because that's all I had. It's still holding : )

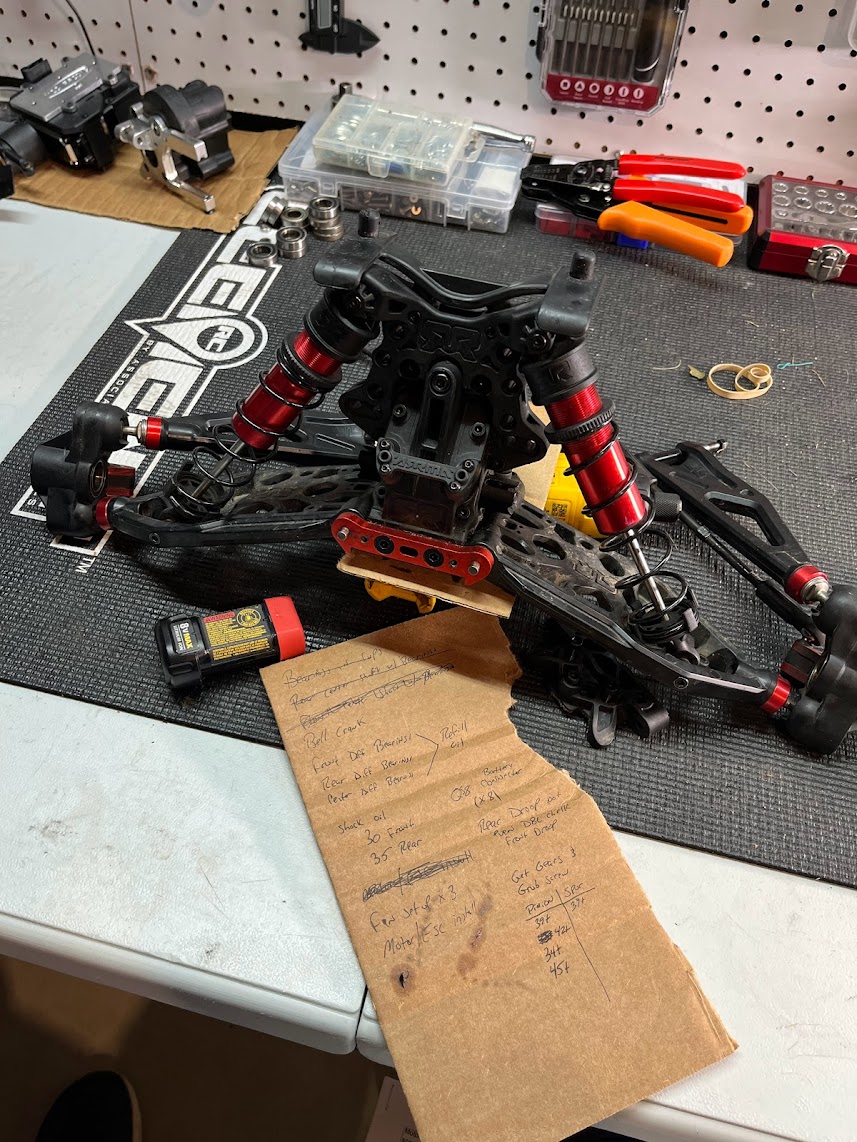

The bench is always changing with new things coming and old things getting stored away.

Picked up the Primal 13130 servo and it was a doozy getting in. It's a hefty unit that takes some finagling to get the lid on the 1/5th box. I had to back out the screws that held the servo in, set the lid, tighten the servo. PSA to anyone trying to get this in their rig. Another one coming below re: where the servo saver meets and pivots on the chassis.

Lots of M2C goodness for this build. These were my first M2C pieces and they are really impressive. I can't wait to give everything a spin.

My 4 y/o's slash needed something fixed during a yard session, but I snapped a pic of my entire work shop. Computer from 2009 and still going strong, though I think there are other people logged in too and took my identity. Nice knowing everyone. 0_0

My dad gave me this extension and I absolutely did not need to use it. But I did and sent him this pic.

Whilst not working on the K8S. We took the family out. The 6s was the smallest rig I was willing to drive. ; )

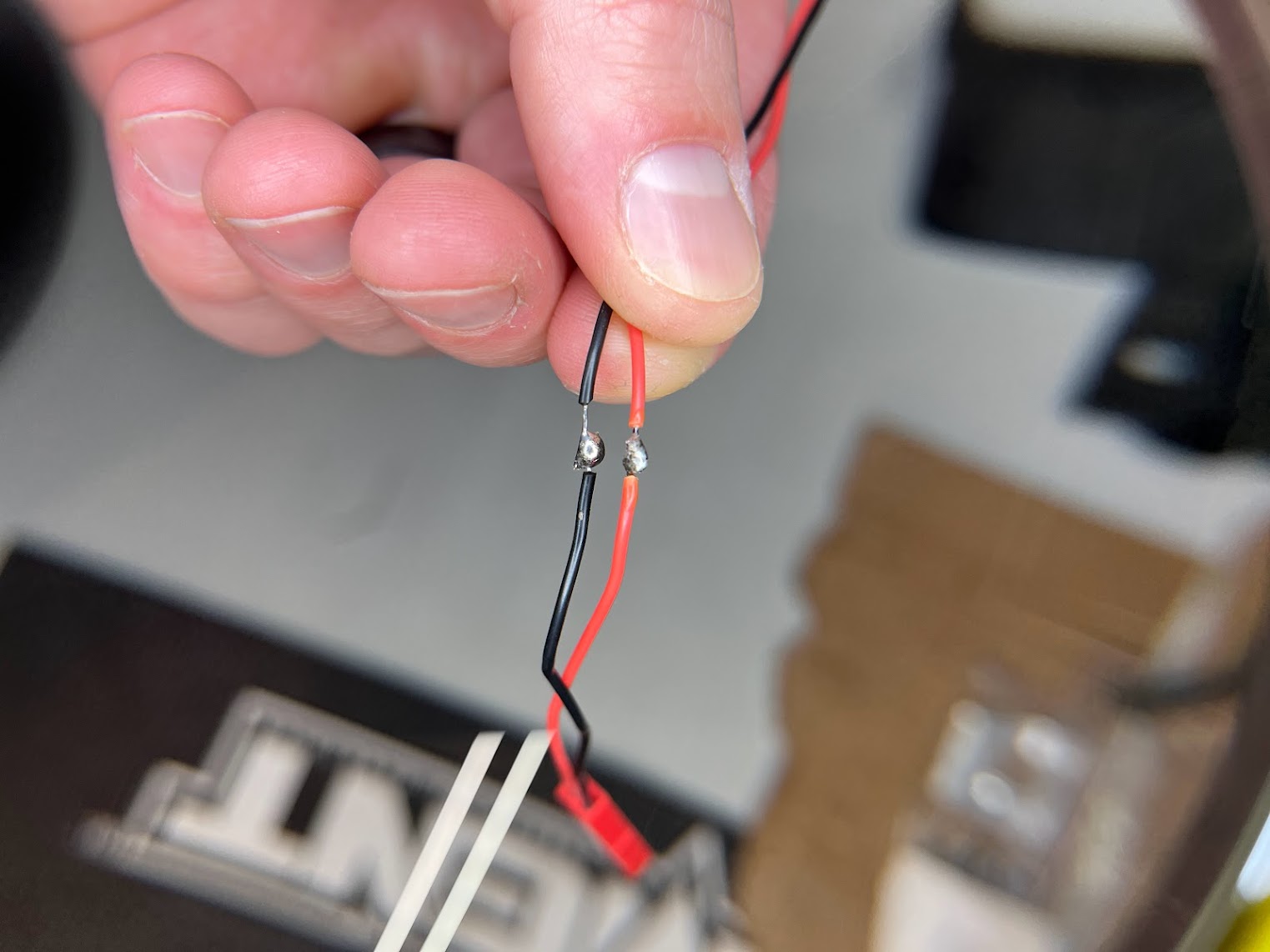

Learning to solder. These were literally me just picking it up and winging it one night. Since then I've done a lot more practicing and will keep doing it until I feel comfortable putting QS8 adapters on my current 4s battery inventory. I also need to know how to solder to get my fan set up correct.

I ended up losing my ESC fan and had no back up, so this is when I decided to strip the car down, service all diffs, replace all bearings, and install the M2C drive train (front & rear center drive shafts + all out drives).

Waiting for bell crank from M2C

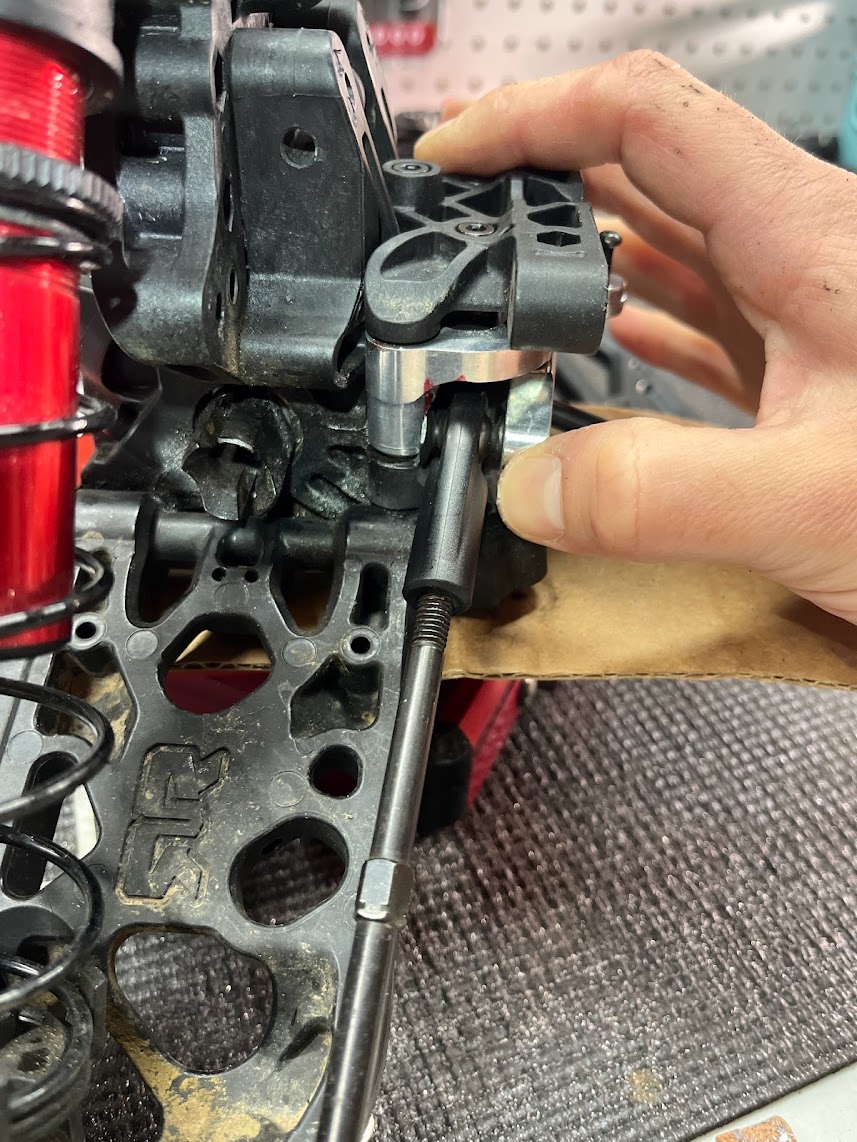

I led with this because it is beautiful, but it took a bunch of elbow grease to get this right. If you didn't already know, you've got to remove a considerable amount of material from the drive side peg to provide space for the steering linkage to full articulate. I was free handing it for a while and still missing, then I used a sharpie to trace where the nut was hitting and shaved down from there. It fits like a glove now, pretty cool.

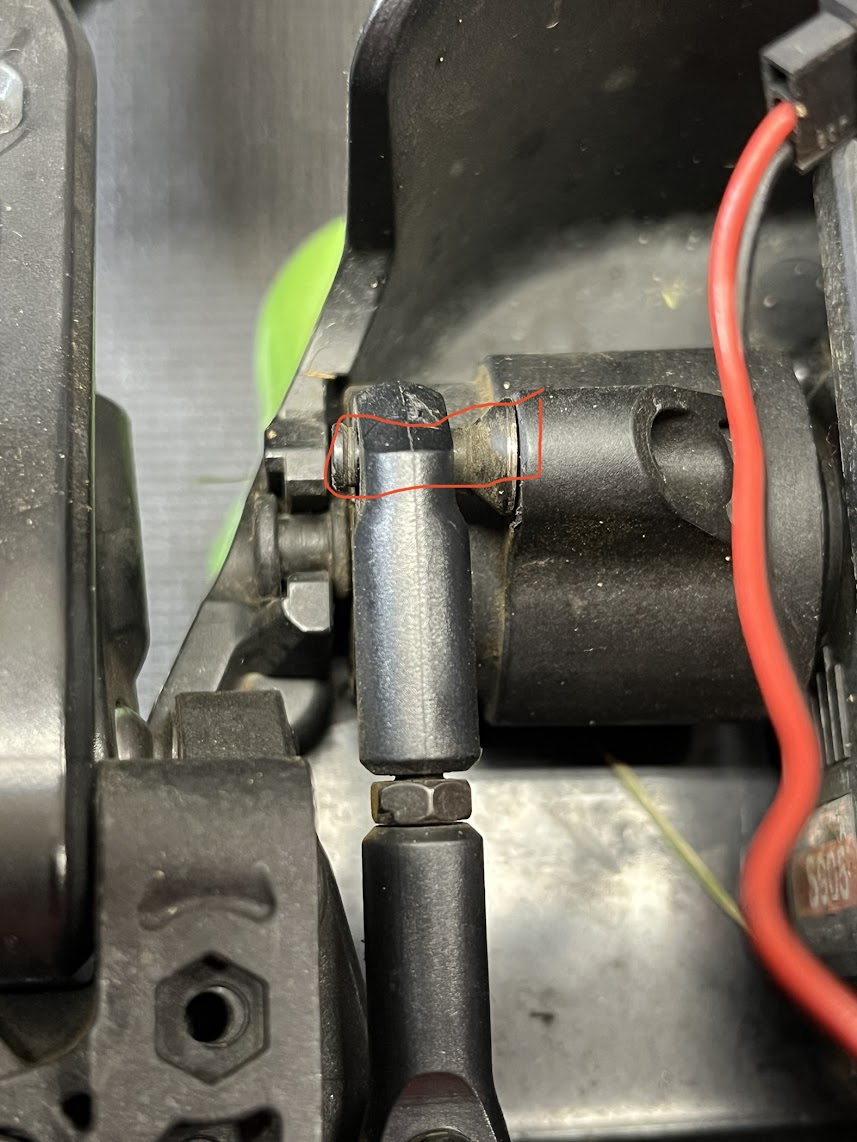

I wish I could reorder these. sorry. After I put the primal servo in I had some trouble with this knob (or whatever it's called). Super loose and something was mega squeaky. Since I took the whole rig apart and serviced it, the squeak is gone and that knob is tight (af!) now.

More

Whatever Arrma uses as tape, it's gnarly. Took me a while to get this tar off.

I'm really sorry these pics are out of order. When I seated the primal servo, I thought I was correct. I was wrong. I stripped a Gear and grabbed a new one

It's beefy

adjusted the center point and also had to Dremel the spot where the servo saver pivots inside the chassis. The primal Is a bit too proud, so I had to free up a little space for the peg to set and articulate.

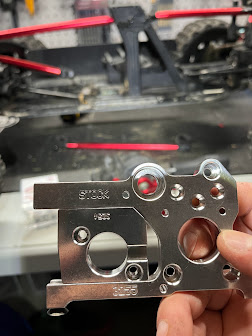

More M2C goodness. Stock motor mount with the 8mm slide for large pinions, model #3254 I believe.

these suck. It broke the first time I used it.

Here's the Dremel section of the bell crank project. I had to use extra deodorant prior to getting into this

The pocket I mentioned in an earlier photo. I'm pleased with how it came out, wish I didn't have to do it.

Didn't have to use these, but bought them just in case

showing full lock

so this was a real kick in the nuts. I finished the bell crank and wanted to reassemble the vehicle to wait for the motor, etc and I snap a screw. Picked up a new one and reassembled. Sigh. It's after the hard work something stupid happens.

this is the last of them for now.

Rounding off this segment of the build were M2C pillow balls. They're lovely.

I was bored and something needed to be vented. This is a metal straw from my buddy's 40th. sharpened up it's the best hole maker I have.

M2C said to use M3x6 screws for the ESC and I'm hoping the taper doesn't give me too much of a gap. The under side is not counter sunk. Has anyone countersunk their own M2C ESC plate? Not really something I want to do nor do I have the tool(s) for.

Rounding off tools. Yay

My first or second solder attempt. It's gotten better since, don't roast me too hard.

Just getting a feel for how to solder bullets for QS8 connectors on my batteries.

Fans are the next bit I have to accomplish for this build, so I picked up KC-RC's gear at the recommendation of @KevinC. The pictures don't do any of this justice. The fan coupler thing is a BEAST. The added hardware is a really nice touch as I was expecting to source all my own. I may not need a third fan for the ESC depending on how the stock one does, but I picked up a stone grate anyway. I'll pair that with some screen to make sure small stones don't get in there.

I am wondering if anyone has done the sorbothane trick with the KC-RC stuff? I'm debating putting some under the fans.

The beginnings of a make shift peg board. I did this with 1x1 boards and screws for Hardie backer board because that's all I had. It's still holding : )

The bench is always changing with new things coming and old things getting stored away.

Picked up the Primal 13130 servo and it was a doozy getting in. It's a hefty unit that takes some finagling to get the lid on the 1/5th box. I had to back out the screws that held the servo in, set the lid, tighten the servo. PSA to anyone trying to get this in their rig. Another one coming below re: where the servo saver meets and pivots on the chassis.

Lots of M2C goodness for this build. These were my first M2C pieces and they are really impressive. I can't wait to give everything a spin.

My 4 y/o's slash needed something fixed during a yard session, but I snapped a pic of my entire work shop. Computer from 2009 and still going strong, though I think there are other people logged in too and took my identity. Nice knowing everyone. 0_0

My dad gave me this extension and I absolutely did not need to use it. But I did and sent him this pic.

Whilst not working on the K8S. We took the family out. The 6s was the smallest rig I was willing to drive. ; )

Learning to solder. These were literally me just picking it up and winging it one night. Since then I've done a lot more practicing and will keep doing it until I feel comfortable putting QS8 adapters on my current 4s battery inventory. I also need to know how to solder to get my fan set up correct.

I ended up losing my ESC fan and had no back up, so this is when I decided to strip the car down, service all diffs, replace all bearings, and install the M2C drive train (front & rear center drive shafts + all out drives).

Waiting for bell crank from M2C

I led with this because it is beautiful, but it took a bunch of elbow grease to get this right. If you didn't already know, you've got to remove a considerable amount of material from the drive side peg to provide space for the steering linkage to full articulate. I was free handing it for a while and still missing, then I used a sharpie to trace where the nut was hitting and shaved down from there. It fits like a glove now, pretty cool.

I wish I could reorder these. sorry. After I put the primal servo in I had some trouble with this knob (or whatever it's called). Super loose and something was mega squeaky. Since I took the whole rig apart and serviced it, the squeak is gone and that knob is tight (af!) now.

More

Whatever Arrma uses as tape, it's gnarly. Took me a while to get this tar off.

I'm really sorry these pics are out of order. When I seated the primal servo, I thought I was correct. I was wrong. I stripped a Gear and grabbed a new one

It's beefy

adjusted the center point and also had to Dremel the spot where the servo saver pivots inside the chassis. The primal Is a bit too proud, so I had to free up a little space for the peg to set and articulate.

More M2C goodness. Stock motor mount with the 8mm slide for large pinions, model #3254 I believe.

these suck. It broke the first time I used it.

Here's the Dremel section of the bell crank project. I had to use extra deodorant prior to getting into this

The pocket I mentioned in an earlier photo. I'm pleased with how it came out, wish I didn't have to do it.

Didn't have to use these, but bought them just in case

showing full lock

so this was a real kick in the nuts. I finished the bell crank and wanted to reassemble the vehicle to wait for the motor, etc and I snap a screw. Picked up a new one and reassembled. Sigh. It's after the hard work something stupid happens.

this is the last of them for now.

Rounding off this segment of the build were M2C pillow balls. They're lovely.

I was bored and something needed to be vented. This is a metal straw from my buddy's 40th. sharpened up it's the best hole maker I have.

M2C said to use M3x6 screws for the ESC and I'm hoping the taper doesn't give me too much of a gap. The under side is not counter sunk. Has anyone countersunk their own M2C ESC plate? Not really something I want to do nor do I have the tool(s) for.

Rounding off tools. Yay

My first or second solder attempt. It's gotten better since, don't roast me too hard.

Just getting a feel for how to solder bullets for QS8 connectors on my batteries.

Fans are the next bit I have to accomplish for this build, so I picked up KC-RC's gear at the recommendation of @KevinC. The pictures don't do any of this justice. The fan coupler thing is a BEAST. The added hardware is a really nice touch as I was expecting to source all my own. I may not need a third fan for the ESC depending on how the stock one does, but I picked up a stone grate anyway. I'll pair that with some screen to make sure small stones don't get in there.

I am wondering if anyone has done the sorbothane trick with the KC-RC stuff? I'm debating putting some under the fans.

Last edited: