- Messages

- 319

- Reaction score

- 456

- Arrma RC's

- Infraction

- Kraton EXB

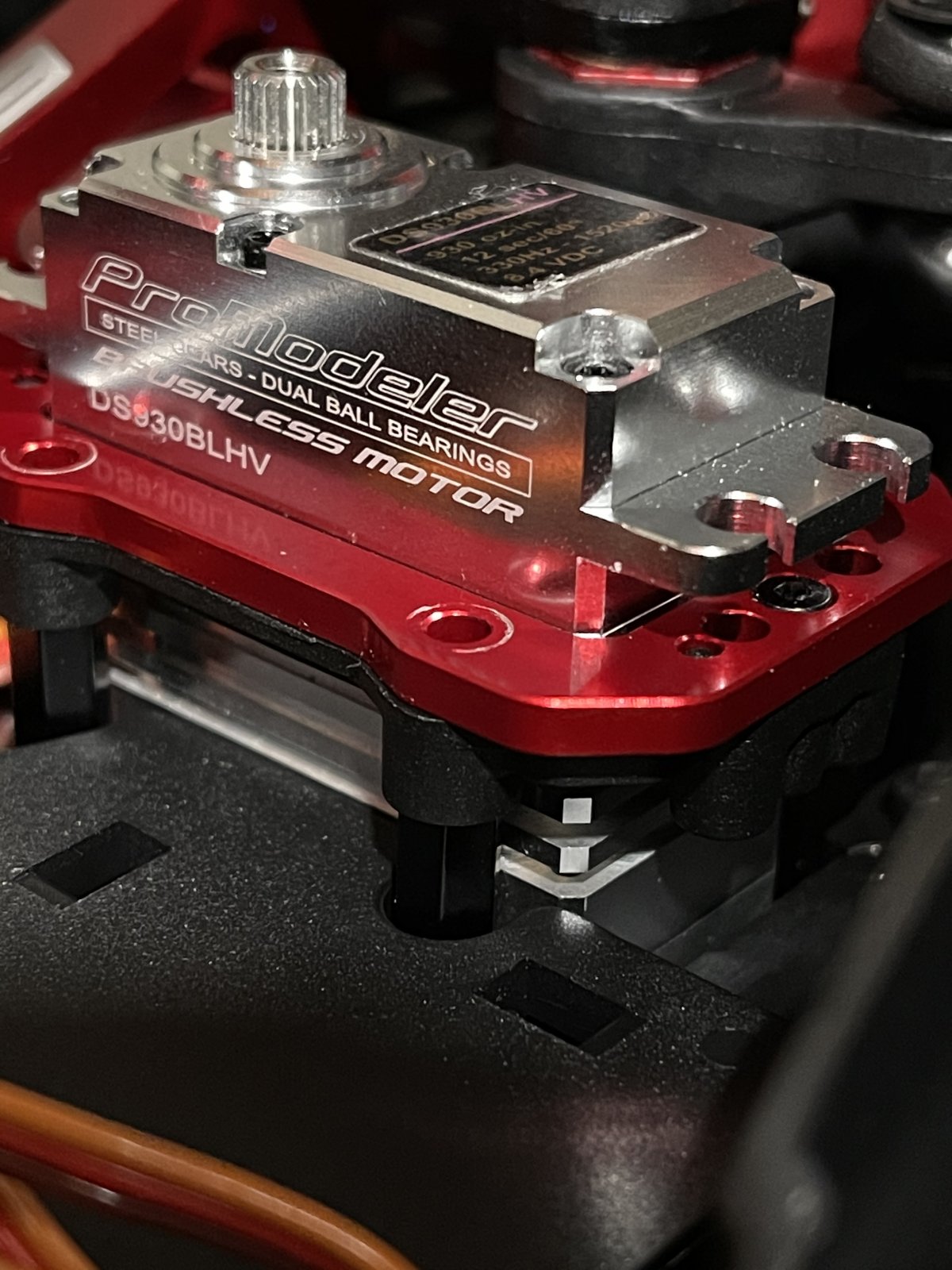

Anyone using a 930 ProModeler on their EXB? Prob. overkill but had it laying around? I’d need quite a stack of the stock plastic shims, that seems a bad idea. Any good off the shelf solutions? Would be a pretty small block to fab without a mill, I’d need to fill a gap a little bigger than in pic to space bottom off chassis.

I’d need quite a stack of the stock plastic shims, that seems a bad idea. Any good off the shelf solutions? Would be a pretty small block to fab without a mill, I’d need to fill a gap a little bigger than in pic to space bottom off chassis.