- Messages

- 10,104

- Reaction score

- 24,868

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

One thing racers and speed runners both do is warm their LiPos. Warm LiPos flow current better and the internal resistance drops.

In the past I have put LiPos up on the dash and ran my defroster. With summer coming I just cant run the heater/defroster when it is hot outside on a 1hr drive to my run location.

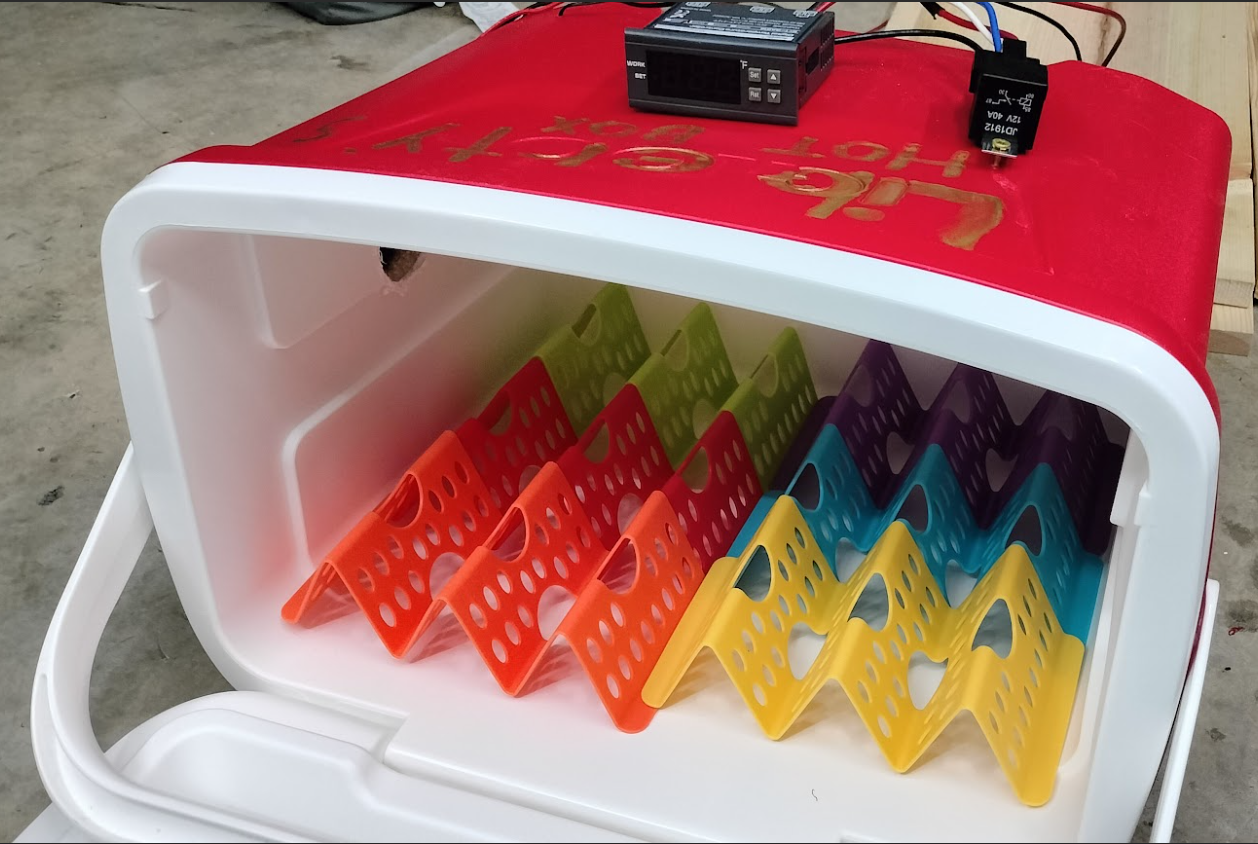

I decided it was time to make a "hot box". When I run multiple setups during a day I might have as many as 8 LiPos that I want to keep warm so this would dictate what size "box" you need. Insulation is a consideration as well. I have seen people use ammo cans and line them with some insulation, but I wanted something a little larger and this idea took care of a few birds with one stone.

The part I have not figured out is how the temps will run. My thought is maybe an initial high temp like 170f and then after x-number of minutes turn it back down to the desired set temp of 115 - 125 F. (these temp ranges would be safe for all the plastic of the cooler and taco holders)

The setup is the following:

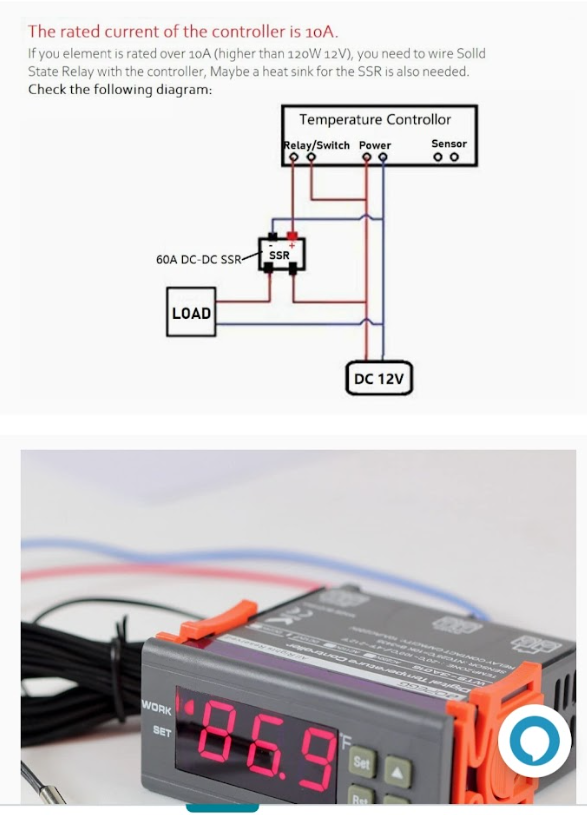

Wiring setup for this is a bit interesting....

The temp controller is more or less a switch and not rated for big amperage, for that reason, I also included the 40a relay in the design.

Originally I had picked up a solid-state relay but is just waaaay to large and went back to using a standard automotive relay.

The way this all will work is power is supplied to the temp controller and the relay.

The temp controller obviously will have a thermostat that turns the signal on when the heater needs to run. That signal is sent to the relay that connects the power supply to the heater/fan element.

The only thing I am currently debating on changing would be to move the fan and heater inside the box and close the hole up. For now, I'll try it as is.

Everything is positioned in a way where this will sit on the passenger seat of my car facing me. I'll be able to open the lid and shoot the lipos with an IR gun to double-check that everything is going ok.

The Taco holders were a simple and low-cost solution to make sure the lipos are exposed to heat from all sides. They have holes in them allowing airflow to move around.

Waiting on some very small screws to arrive from Amazon to screw them down.

It is not 100% complete but was excited to share the project that I think is pretty interesting.

In the past I have put LiPos up on the dash and ran my defroster. With summer coming I just cant run the heater/defroster when it is hot outside on a 1hr drive to my run location.

I decided it was time to make a "hot box". When I run multiple setups during a day I might have as many as 8 LiPos that I want to keep warm so this would dictate what size "box" you need. Insulation is a consideration as well. I have seen people use ammo cans and line them with some insulation, but I wanted something a little larger and this idea took care of a few birds with one stone.

The part I have not figured out is how the temps will run. My thought is maybe an initial high temp like 170f and then after x-number of minutes turn it back down to the desired set temp of 115 - 125 F. (these temp ranges would be safe for all the plastic of the cooler and taco holders)

The setup is the following:

| Part Name | Purchase info |

| 41 can cooler | Walmart |

| 40a 12v relay | https://www.amazon.com/dp/B078T8CMF6?psc=1&ref=ppx_yo2ov_dt_b_product_details |

| Digital temp controller with sensor | https://www.amazon.com/dp/B011VGAPOC?psc=1&ref=ppx_yo2ov_dt_b_product_details |

| 12v heater element with fan | https://www.amazon.com/dp/B0BJ9ZFMSC?psc=1&ref=ppx_yo2ov_dt_b_product_details |

| taco holders | https://www.amazon.com/dp/B0BQQ6C1QL?psc=1&ref=ppx_yo2ov_dt_b_product_details |

Wiring setup for this is a bit interesting....

The temp controller is more or less a switch and not rated for big amperage, for that reason, I also included the 40a relay in the design.

Originally I had picked up a solid-state relay but is just waaaay to large and went back to using a standard automotive relay.

The way this all will work is power is supplied to the temp controller and the relay.

The temp controller obviously will have a thermostat that turns the signal on when the heater needs to run. That signal is sent to the relay that connects the power supply to the heater/fan element.

The only thing I am currently debating on changing would be to move the fan and heater inside the box and close the hole up. For now, I'll try it as is.

Everything is positioned in a way where this will sit on the passenger seat of my car facing me. I'll be able to open the lid and shoot the lipos with an IR gun to double-check that everything is going ok.

The Taco holders were a simple and low-cost solution to make sure the lipos are exposed to heat from all sides. They have holes in them allowing airflow to move around.

Waiting on some very small screws to arrive from Amazon to screw them down.

It is not 100% complete but was excited to share the project that I think is pretty interesting.

Last edited: