Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Motor Support

- Thread starter Alejo90

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

- Messages

- 6,175

- Reaction score

- 9,041

- Location

- Illinois

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton EXB

- Talion

- Typhon 6s

- Typhon TLR

Check out thingiverse. There are several options if I remember correctly.

332_RC

Very Active Member

- Messages

- 1,923

- Reaction score

- 5,094

- Location

- USA, Georgia

- Arrma RC's

- Gorgon

- Infraction

- Kraton 6s

- Notorious

- Senton 3s

- Infraction 4x4

Maybe this can help?

https://www.ebay.com/itm/3344027959...q7FPNHENTvG&var=&widget_ver=artemis&media=SMS

I know it's not the STL file but an idea of what's out there. Hope it helps at least.

https://www.thingiverse.com/thing:4982263

https://www.ebay.com/itm/3344027959...q7FPNHENTvG&var=&widget_ver=artemis&media=SMS

I know it's not the STL file but an idea of what's out there. Hope it helps at least.

STLMaybe this can help?

https://www.ebay.com/itm/3344027959...q7FPNHENTvG&var=&widget_ver=artemis&media=SMS

I know it's not the STL file but an idea of what's out there. Hope it helps at least.

https://www.thingiverse.com/thing:4982263

Last edited:

Greengaunja

Ise da by' dat burns da Senton........

Premium Member

ArrmaForum Fan

Build Thread Contributor

- Messages

- 2,664

- Reaction score

- 4,529

- Location

- Durham Region, Ontario Canuckistan

- Arrma RC's

- Senton 6s

- Senton 3s

I've been seeing those pop up everywhere. I'm curious as to whether they actually work or is it just another gimmick?Maybe this can help?

https://www.ebay.com/itm/3344027959...q7FPNHENTvG&var=&widget_ver=artemis&media=SMS

I know it's not the STL file but an idea of what's out there. Hope it helps at least.

STL

https://www.thingiverse.com/thing:4982263

RCbuzz

Very Active Member

- Messages

- 2,904

- Reaction score

- 5,109

- Arrma RC's

- Granite

- Kraton 8S

- Kraton 6s

- Mojave EXB

- Senton 3s

Check here under 3S: "protection/support"

Other lots of good designs shared with the community as well.

https://www.arrmaforum.com/threads/repository-of-useful-free-rc-3d-print-designs-updated.60584/

Other lots of good designs shared with the community as well.

https://www.arrmaforum.com/threads/repository-of-useful-free-rc-3d-print-designs-updated.60584/

332_RC

Very Active Member

- Messages

- 1,923

- Reaction score

- 5,094

- Location

- USA, Georgia

- Arrma RC's

- Gorgon

- Infraction

- Kraton 6s

- Notorious

- Senton 3s

- Infraction 4x4

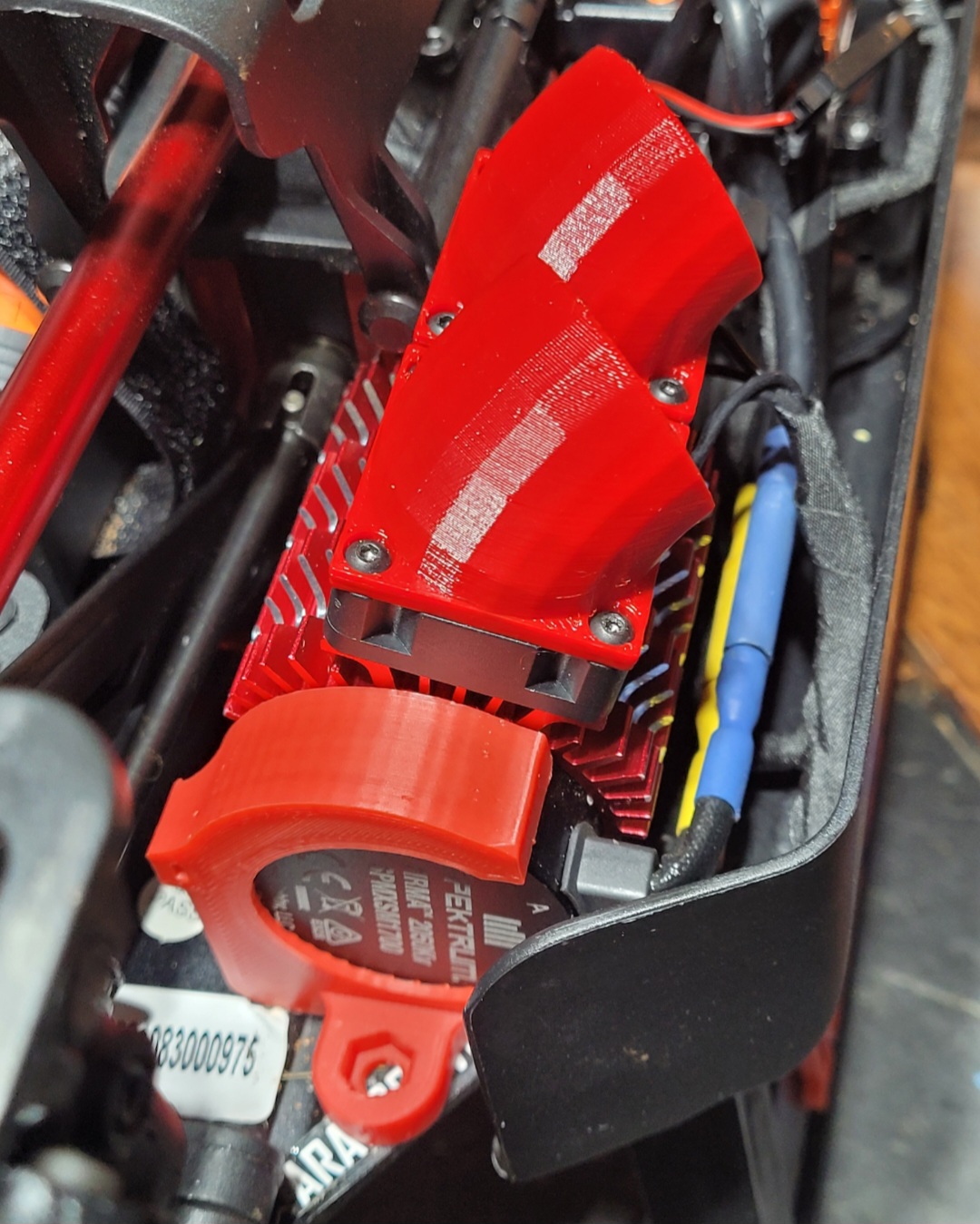

I have one of the 6s printed motor supports on my Notorious from that link above, that sellers store. It works ok. It fits really snug & doesn't move. It has a hole to screw it down but I didn't do that, mine just is snapped under the motor & looks cool & it's functionalI've been seeing those pop up everywhere. I'm curious as to whether they actually work or is it just another gimmick?

332_RC

Very Active Member

- Messages

- 1,923

- Reaction score

- 5,094

- Location

- USA, Georgia

- Arrma RC's

- Gorgon

- Infraction

- Kraton 6s

- Notorious

- Senton 3s

- Infraction 4x4

A pic

332_RC

Very Active Member

- Messages

- 1,923

- Reaction score

- 5,094

- Location

- USA, Georgia

- Arrma RC's

- Gorgon

- Infraction

- Kraton 6s

- Notorious

- Senton 3s

- Infraction 4x4

The scoops are worthless though. Just cool looking. Just pulls dirt all in the fans. Support does its job

- Messages

- 6,175

- Reaction score

- 9,041

- Location

- Illinois

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton EXB

- Talion

- Typhon 6s

- Typhon TLR

They help prevent the motor mount from bendingI've been seeing those pop up everywhere. I'm curious as to whether they actually work or is it just another gimmick?

332_RC

Very Active Member

- Messages

- 1,923

- Reaction score

- 5,094

- Location

- USA, Georgia

- Arrma RC's

- Gorgon

- Infraction

- Kraton 6s

- Notorious

- Senton 3s

- Infraction 4x4

And that's an old photo. I took the scoops off & have reg shroudsThe scoops are worthless though. Just cool looking. Just pulls dirt all in the fans. Support does its job

Greengaunja

Ise da by' dat burns da Senton........

Premium Member

ArrmaForum Fan

Build Thread Contributor

- Messages

- 2,664

- Reaction score

- 4,529

- Location

- Durham Region, Ontario Canuckistan

- Arrma RC's

- Senton 6s

- Senton 3s

Yeah I get that part. However, I've learned that for every part strengthened, you create a weak spot somewhere. Personally I use foam/rubber shelf padding tucked under my motors.and get a 50/50 between it bending and flexing. Then again I'm not a "jumper" with my RCs so I can see a benefit in totally eliminating flex for those hard landings.They help prevent the motor mount from bending

Use some fine meshed stainless steel screenings. Not window mesh, this one came from an eavestrough cover:The scoops are worthless though. Just cool looking. Just pulls dirt all in the fans. Support does its job

Last edited:

332_RC

Very Active Member

- Messages

- 1,923

- Reaction score

- 5,094

- Location

- USA, Georgia

- Arrma RC's

- Gorgon

- Infraction

- Kraton 6s

- Notorious

- Senton 3s

- Infraction 4x4

That looks awesome! Ive thought of using K&N pre-filter there. I have one left over from a car filter.Yeah I get that part. However, I've learned that for every part strengthened, you create a weak spot somewhere. Personally I use foam/rubber shelf padding tucked under my motors.and get a 50/50 between it bending and flexing. Then again I'm not a "jumper" with my RCs so I can see a benefit in totally eliminating flex for those hard landings.

Use some fine meshed stainless steel screenings. Not window mesh, this one came from an eavestrough cover:

View attachment 340972

I'm building a K6 slider. 4282 can. I'm gonna use Buna O-rings around the motor to support it against the chassis.

- Thread starter

- #13

Thanks found the file now just someone to print it for me appreciateMaybe this can help?

https://www.ebay.com/itm/3344027959...q7FPNHENTvG&var=&widget_ver=artemis&media=SMS

I know it's not the STL file but an idea of what's out there. Hope it helps at least.

STL

https://www.thingiverse.com/thing:4982263

332_RC

Very Active Member

- Messages

- 1,923

- Reaction score

- 5,094

- Location

- USA, Georgia

- Arrma RC's

- Gorgon

- Infraction

- Kraton 6s

- Notorious

- Senton 3s

- Infraction 4x4

@Tex KoderThanks found the file now just someone to print it for me appreciate

parcou

Premium Member!

Premium Member

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 6,236

- Reaction score

- 9,147

- Location

- Memphis, TN

- Arrma RC's

- BigRock

- Felony

- Fireteam

- Granite

- Infraction

- Kraton EXB

- Talion EXB

- Typhon TLR

- Vorteks

Welcome!Looking for a 3D file to get a 3d printed engine support for my 3s big rock if anyone has one could be appreciated or point me in the direction

I do not have a 3D printer (issue for me), and I have found thick O-rings have done a great job for me over the end of the motor. Finding the right size is tricky so I invested in an o-ring kit. Pic is of a 6S, but you can do the same for a 3S motor.

Oring kit, example can find on Amazon, ebay, all over

https://www.harborfreight.com/382-piece-o-ring-assortment-67554.html

- Messages

- 6,175

- Reaction score

- 9,041

- Location

- Illinois

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton EXB

- Talion

- Typhon 6s

- Typhon TLR

PM me if you still need help with thisThanks found the file now just someone to print it for me appreciate

Tex Koder

2D , 3D Not a problem. I'll take that Challenge.

Lifetime Premium!

Premium Member

ArrmaForum Fan

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 10,048

- Reaction score

- 25,394

- Location

- Dallas, TX (USA)

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Mojave

- Nero

- Senton 3s

- Typhon 6s

- Vendetta

- Thread starter

- #18

I could love to get the help from one of you guys but I'm assuming most of ya are in the states I'm locates in Canada hhehe

Greengaunja

Ise da by' dat burns da Senton........

Premium Member

ArrmaForum Fan

Build Thread Contributor

- Messages

- 2,664

- Reaction score

- 4,529

- Location

- Durham Region, Ontario Canuckistan

- Arrma RC's

- Senton 6s

- Senton 3s

Whereabouts? Locally we have one of these and I know guys who have used them with no complaints.I could love to get the help from one of you guys but I'm assuming most of ya are in the states I'm locates in Canada hhehe

https://www.i3dstore.ca/

Also,hit up FB Market. There are always ads for 3d printing but how good they are is anyone's guess.

- Thread starter

- #20

I did find someone in Facebook market to do the small part and not a bad deal 2 supports for 30Whereabouts? Locally we have one of these and I know guys who have used them with no complaints.

https://www.i3dstore.ca/

Also,hit up FB Market. There are always ads for 3d printing but how good they are is anyone's guess.

Similar threads

- Replies

- 1

- Views

- 121

- Replies

- 1

- Views

- 211