MrWednesday

Active Member

- Messages

- 221

- Reaction score

- 396

- Arrma RC's

- Infraction

- Kraton 8S

- Kraton EXB

- Nero

- Outcast 8s

- Outcast EXB

- Senton 6s

TLDR: I’m a serial killer

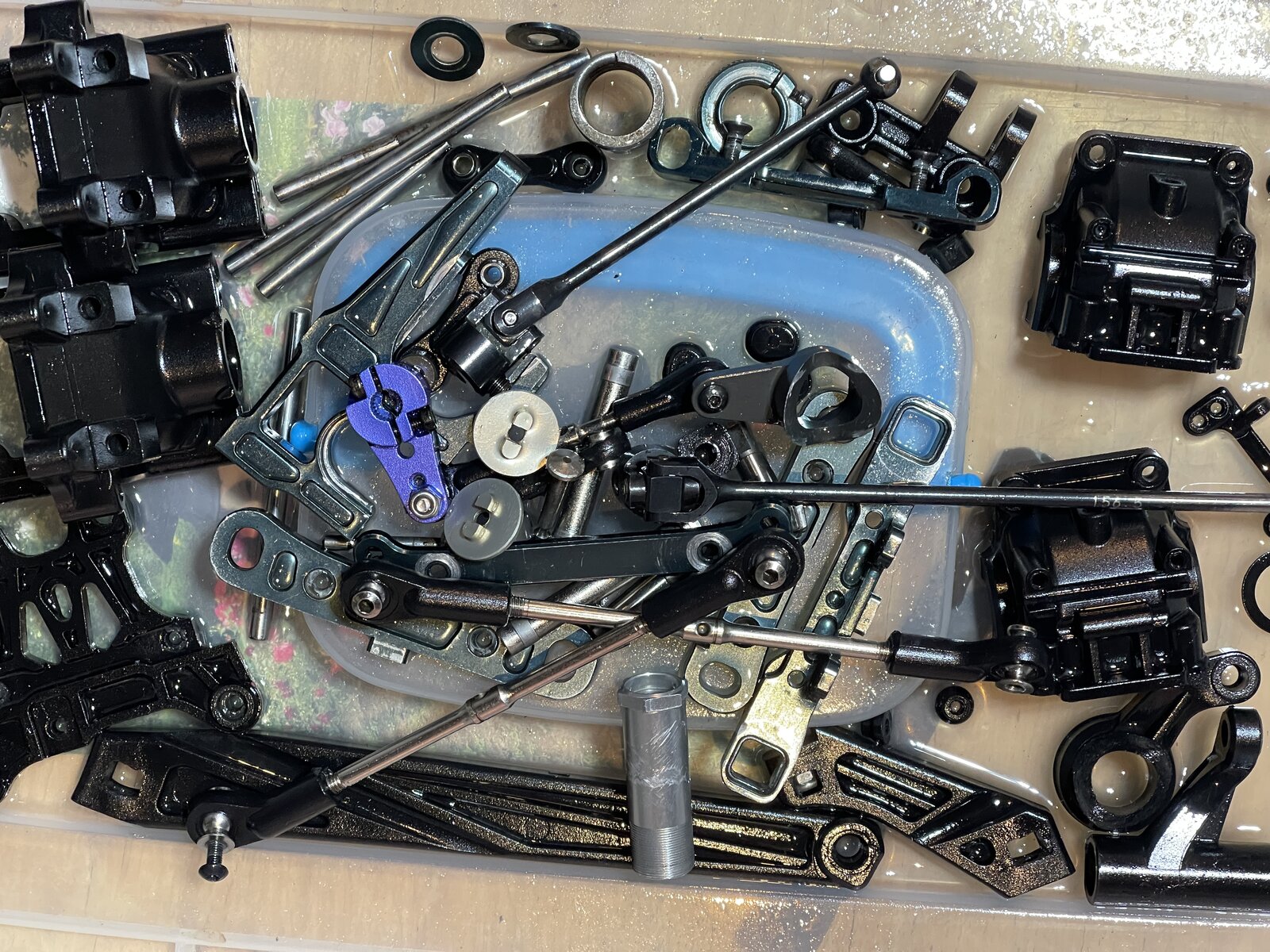

Doing a 100% teardown on my MBX8TR eco. Please tell me if I’m neglecting something:

I feel like I get a bit ridiculous, I start by taking the set screws out of the sway bar mounts, every single thing is completely disassembled except the receiver.

Best part is, I barely even notice a difference n performance after doing all that because I’m inexperienced and a shït driver. Good thing is I only really drive my RCs like once every few weeks so I don’t have to do this more than 2-3 times a year I figure.

Doing a 100% teardown on my MBX8TR eco. Please tell me if I’m neglecting something:

I feel like I get a bit ridiculous, I start by taking the set screws out of the sway bar mounts, every single thing is completely disassembled except the receiver.

- I strip down the servo, make sure all the dentistry looks sharp.

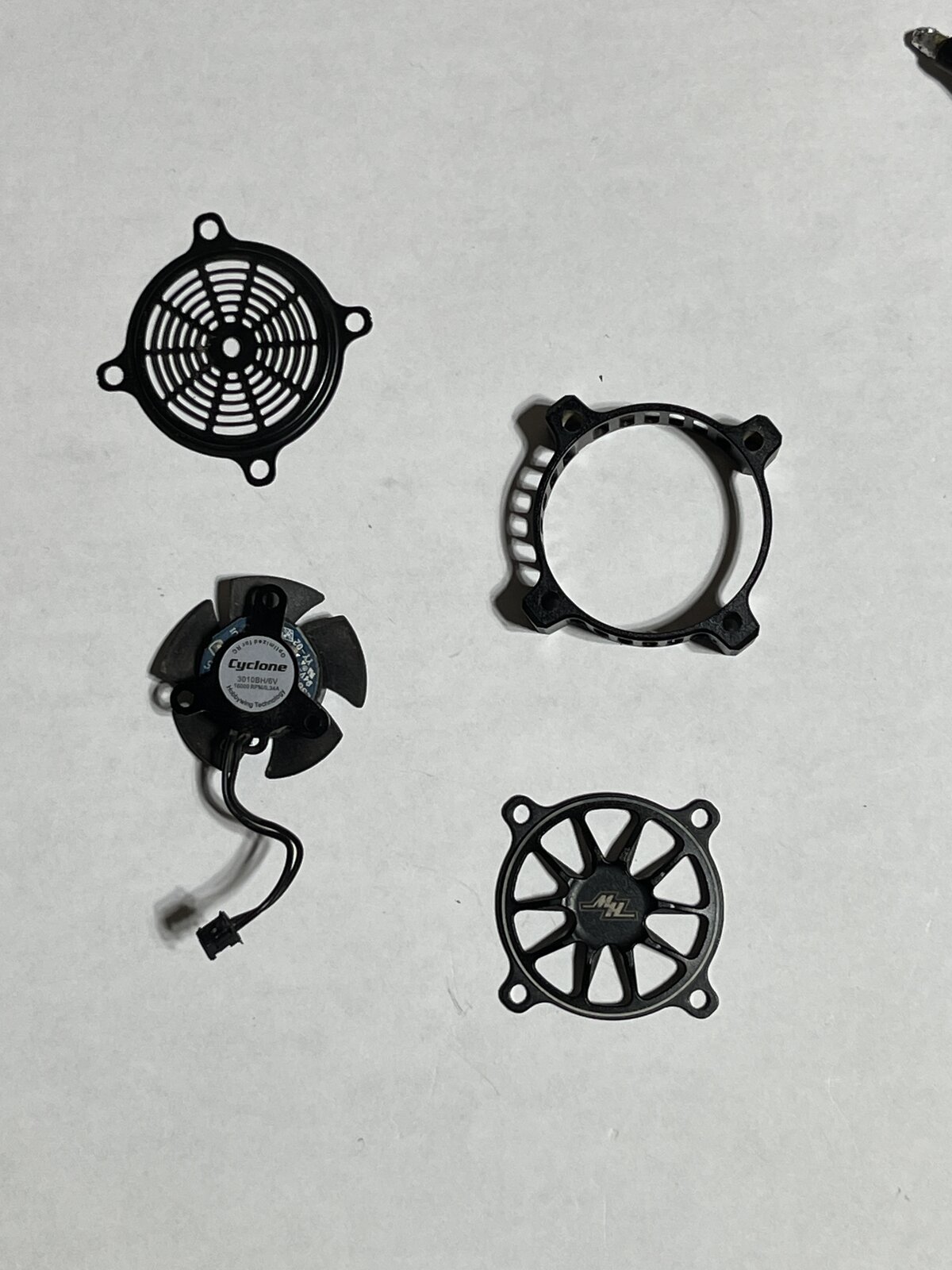

- The ESC (XR8 Plus G2S) gets dissected replace fan is necessary.

- I take the motor (Xerun 2200 G3) apart completely.

- Obviously I do all the bearings very thoroughly

- Clean all the plastic with car wash soap, put it all in a WD-40 bath for about a week. Then I take all those parts and I hand clean every single GD one with Cleano aviation grade degreaser (no VOCs). Following that I use 210 aviation plastic cleaner and polisher on them.

- For the body I use Rejex soil barrier.

- I replace any wires that don’t look perfect as well as battery connectors.

- Shocks gets fully disassembled, I usually save the silicone if it’s clean, but I inspect every single part. Springs get tested with a micrometer and a digital scale, usually get replaced because they’re pretty cheap and I have a stockpile of new ones since I have other older Mugen Truggies. if they’re still firm they get cleaned with a wire brush.

- Differentials are completely torn appart, gears and shims scrubbed clean, old silicone discarded and replaced

- Sand and polish sway bars

- I put all the screws from the entire truck in a solvent bath and then clean them one at a time by putting them on the end of a drill and spinning them against a wire brush then a linen cloth. I mean if I’m going to clean every screw hole with a pipe cleaner there’s no sense putting dirty screws back in… right

? I can’t be the only one that does this specific part right boys?

? I can’t be the only one that does this specific part right boys? - I use dry chain lube all over the exposed drive train where friction of any kind occurs, as well as pillow balls. This is a step I do about an hour before every single run as well.

Best part is, I barely even notice a difference n performance after doing all that because I’m inexperienced and a shït driver. Good thing is I only really drive my RCs like once every few weeks so I don’t have to do this more than 2-3 times a year I figure.