ph47mf

Active Member

- Thread starter

- #41

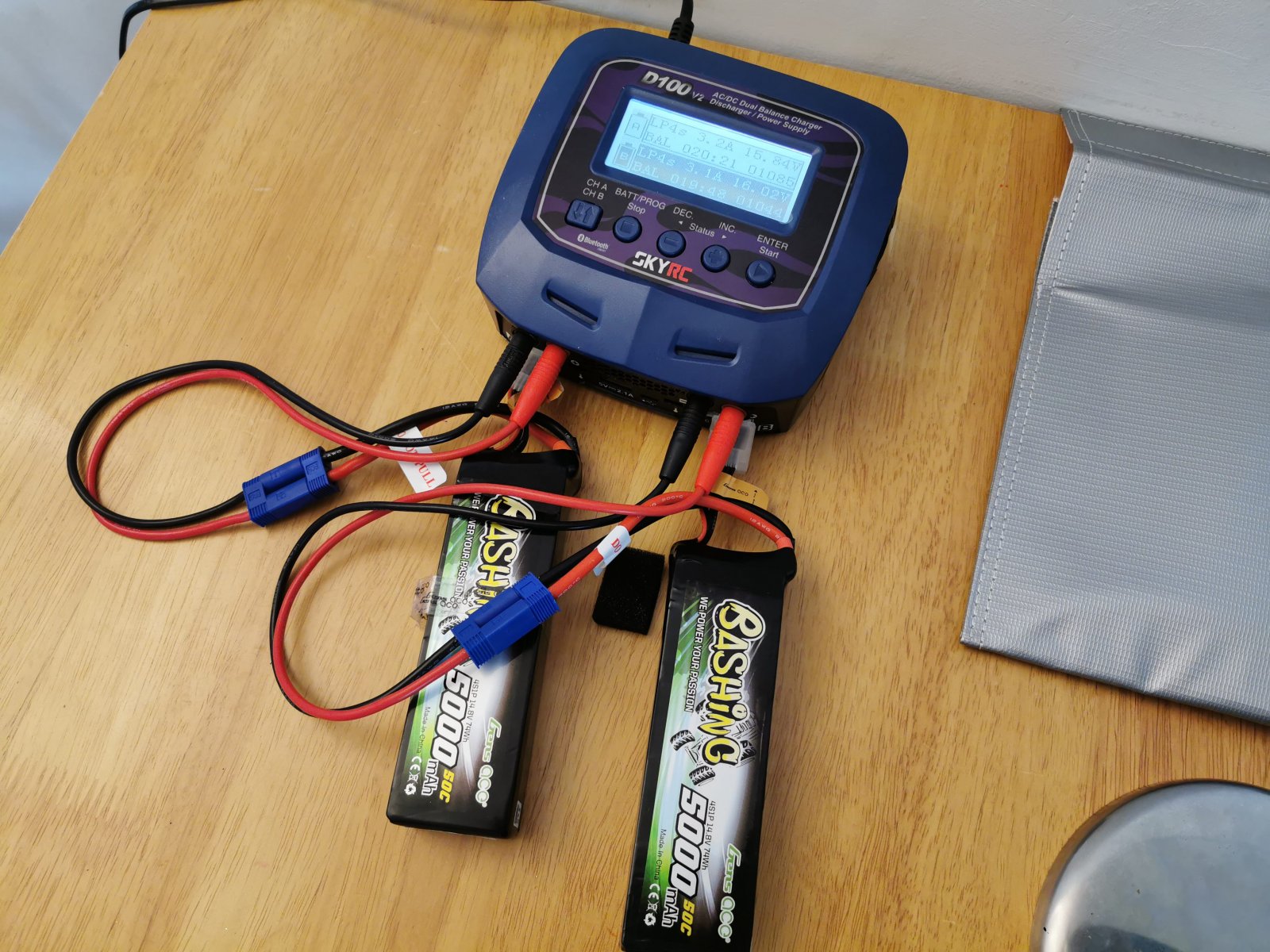

Happy weekend guys! An opportunity to take it out again so got 2 Lipos charged - 1st issue - 5000mah 4S battery, I selected 5A charge rate but it would only charge at 3A once started, never really go above that, sound about right?

I ran it for 20 minutes, started losing power, thinking god damn it it must be the pinion again so I took it apart again and it's rock solid, the shop did a pretty good job with the TL then found the culprit to be the loose slipper clutch.

Basically I screwed it tight then loosen 1 but it came loose again. So I tried 1/2, 1/4 and still came loose after 10 minutes every time, in the end I couldn't be bothered anymore and just ran it sort of tight (stop as soon as I feel resistance) and that kept it going longer.

1) Can I carry on running like this without burning the car down?

2) If I were to take it apart and add TL to the slipper clutch, which part specifically do I apply to?

I ran it for 20 minutes, started losing power, thinking god damn it it must be the pinion again so I took it apart again and it's rock solid, the shop did a pretty good job with the TL then found the culprit to be the loose slipper clutch.

Basically I screwed it tight then loosen 1 but it came loose again. So I tried 1/2, 1/4 and still came loose after 10 minutes every time, in the end I couldn't be bothered anymore and just ran it sort of tight (stop as soon as I feel resistance) and that kept it going longer.

1) Can I carry on running like this without burning the car down?

2) If I were to take it apart and add TL to the slipper clutch, which part specifically do I apply to?