Just wanted to share my findings with putting a TBR Senton MEGA front bumper on my new Senton 3S BLX. It seems that most parts that fit the Senton MEGA do seem to cross over to the 3S BLX. This assumption was what prompted me to contact TBR to see if they had been able to test the MEGA bumper on the new 3S version of the truck yet. They hadn't.

So we agreed that they would let me return it if it didnt fit. So that was enough for me to give it a shot. TBR seems to think they will develop a 3S version in the future...

But for the MEGA version of the bumper on a 3S BLX, let me start by saying, it doesn't fit. I managed to make it fit with some modifications, but it is not a bolt on affair.

Ive attached some pics to help show what I did to make it fit.

Basically, it appears that the new front diff housing is shaped slightly differently, it has a bit of a point on the front, whereas the MEGA must be flat vertically. (don't have one to confirm, but based on the shape of the TBR parts, this must be true)

Anyway, when you try to put the flat TBR bumper brace on, it doesn't sit flat. If you tighten the screws, it pulls away from the red aluminum control arm pin support.

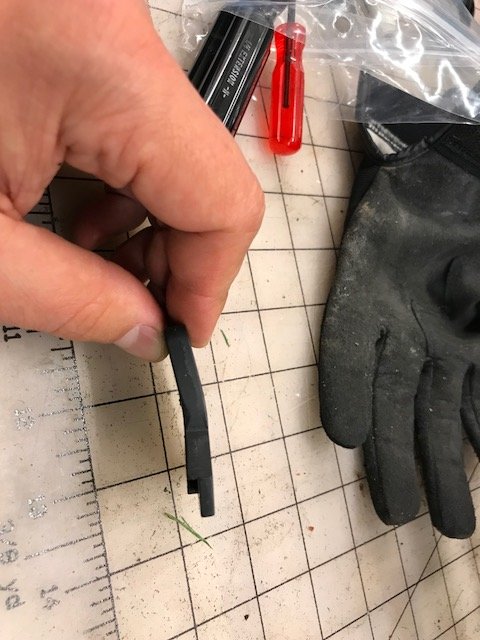

So thats a no-go. From what I could tell, the brace/plate that mounts to the front diff housing needed a bend in it. Its made of Delrin, so it seems to need a bit more heat to bend it than some other plastics Ive worked with, but it was possible using a heat gun. So after determining where I wanted the bend, I heated it up and put a mild bend in it. This seemed to solve the issue.

Though the upper support that bolts the bumper to the plate didnt quite fit right at this point either. So this needed a small upward bend where it bolts to the mounting block, just to reduce stress and to make things line up better.

So once I figured that part out I bolted it all together and all seemed good. But then I noticed that when the bumper was pushed upward, as if climbing over something, all was fine, but if the bumper was pushed downward, the delrin support plate would flex and pull away from the red aluminum control arm support along the bottom. I felt that this type of downward force was unlikely, but not impossible during a tumble of some kind. So I added a small metal bracket in between the chasis and the TBR bumper. This bracket gets held on by the large underside allen bolt, and reduces the likelihood that the parts would flex enough to separate at the bottom portion near the control arm supports.

Then the finished product:

Im not sure if this is clear enough for someone to try to duplicate it, but Im hoping it is. If not, I can try to answer questions.

So we agreed that they would let me return it if it didnt fit. So that was enough for me to give it a shot. TBR seems to think they will develop a 3S version in the future...

But for the MEGA version of the bumper on a 3S BLX, let me start by saying, it doesn't fit. I managed to make it fit with some modifications, but it is not a bolt on affair.

Ive attached some pics to help show what I did to make it fit.

Basically, it appears that the new front diff housing is shaped slightly differently, it has a bit of a point on the front, whereas the MEGA must be flat vertically. (don't have one to confirm, but based on the shape of the TBR parts, this must be true)

Anyway, when you try to put the flat TBR bumper brace on, it doesn't sit flat. If you tighten the screws, it pulls away from the red aluminum control arm pin support.

So thats a no-go. From what I could tell, the brace/plate that mounts to the front diff housing needed a bend in it. Its made of Delrin, so it seems to need a bit more heat to bend it than some other plastics Ive worked with, but it was possible using a heat gun. So after determining where I wanted the bend, I heated it up and put a mild bend in it. This seemed to solve the issue.

Though the upper support that bolts the bumper to the plate didnt quite fit right at this point either. So this needed a small upward bend where it bolts to the mounting block, just to reduce stress and to make things line up better.

So once I figured that part out I bolted it all together and all seemed good. But then I noticed that when the bumper was pushed upward, as if climbing over something, all was fine, but if the bumper was pushed downward, the delrin support plate would flex and pull away from the red aluminum control arm support along the bottom. I felt that this type of downward force was unlikely, but not impossible during a tumble of some kind. So I added a small metal bracket in between the chasis and the TBR bumper. This bracket gets held on by the large underside allen bolt, and reduces the likelihood that the parts would flex enough to separate at the bottom portion near the control arm supports.

Then the finished product:

Im not sure if this is clear enough for someone to try to duplicate it, but Im hoping it is. If not, I can try to answer questions.