Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Big Rock Strange slipper damage?

- Thread starter Robingro

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

- Messages

- 2,112

- Reaction score

- 3,015

- Location

- Massachusetts USA 🇺🇸

- Arrma RC's

- Limitless

- Kraton EXB

- Typhon 3s

- Typhon 6s

Had one do the same a while back on a typhon 3s, Luckily it’s not too expensive

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,770

- Reaction score

- 42,291

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

Yeah that thing is made of monkey metal that is a very common breakage.

In ma hoose, any strange slipper damage is usually doon tae the dug!

- Messages

- 1,194

- Reaction score

- 3,307

- Location

- Ontario, Canada

- Arrma RC's

- Fireteam

- Granite

- Granite Mega

- Infraction

- Mojave EXB

- Nero

- Notorious

- Typhon 3s

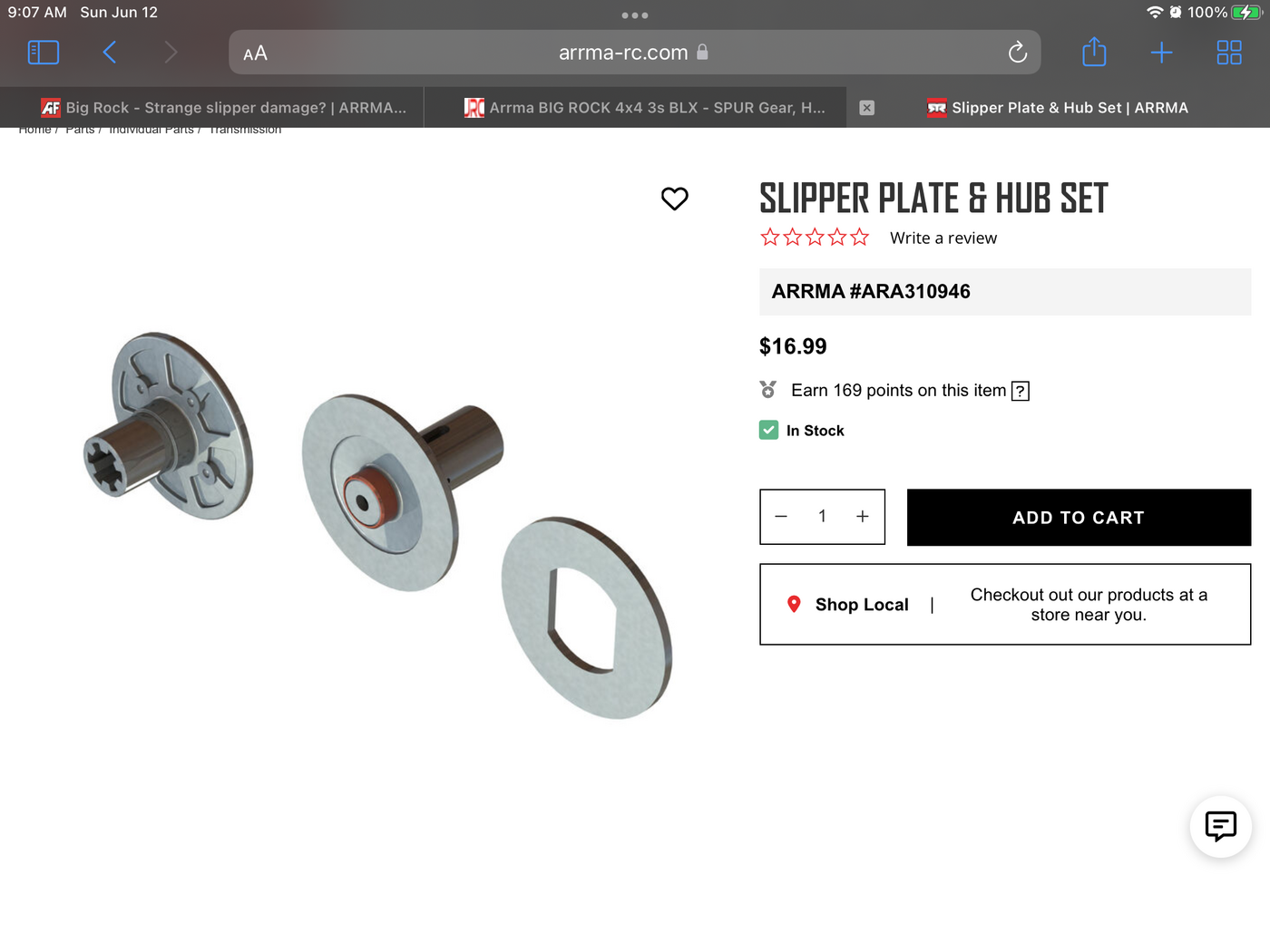

It's a common failure point. I usually add old bearing races to support it.Lost drive when i was doing some backflips with my big rock.

Pulled it apart and noticed the slipper was damaged, nothing else.

Feels like theres alot of plastic parts that should go out first, anyone else had this happened?

View attachment 223132

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,886

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

Slipper's.... I'm so done with them.

Velodromed

Snatching defeat from the jaws of victory!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 7,758

- Reaction score

- 13,925

- Location

- San Antonio, TX

- Arrma RC's

- BigRock 4x4

- Granite

- Kraton 6s

- Kraton 4s

- Notorious

- Outcast 4s

- Vorteks

- Voltage

- Infraction 4x4

Are you clicking the motor module back in very firmly and making sure to get that firm, loud ‘click’ sound? The only time I’ve had it strip out the inside of the slipper hub was when I failed to click it back in 100%. Now if I don’t get that really loud click sound and feel I pop it back out and try again until I do.

The inner bearing race mod previously mentioned works very well. Been running it in four of my 3S cars for quite a while now. It won’t stop it from stripping out on the inside but doing what I said above helps avoid that.

Oh, forgot the other common reason that happens. Landing just right on your ass-end can flex the chassis just enough to separate the spur connection from the rear diff slightly. Add to this landing on power and the hub can strip out/crack.

The inner bearing race mod previously mentioned works very well. Been running it in four of my 3S cars for quite a while now. It won’t stop it from stripping out on the inside but doing what I said above helps avoid that.

Oh, forgot the other common reason that happens. Landing just right on your ass-end can flex the chassis just enough to separate the spur connection from the rear diff slightly. Add to this landing on power and the hub can strip out/crack.

Last edited:

- Messages

- 2,477

- Reaction score

- 2,586

- Arrma RC's

- Granite

A new metal slipper hub sleeve was introduced with the new 4s line. It's not available yet though.

https://www.arrma-rc.com/en/product/metal-slipper-hub-sleeve/ARA311157.html

https://www.arrma-rc.com/en/product/metal-slipper-hub-sleeve/ARA311157.html

Velodromed

Snatching defeat from the jaws of victory!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 7,758

- Reaction score

- 13,925

- Location

- San Antonio, TX

- Arrma RC's

- BigRock 4x4

- Granite

- Kraton 6s

- Kraton 4s

- Notorious

- Outcast 4s

- Vorteks

- Voltage

- Infraction 4x4

Or just slip on an inner race from an old bearing.A new metal slipper hub sleeve was introduced with the new 4s line. It's not available yet though.

https://www.arrma-rc.com/en/product/metal-slipper-hub-sleeve/ARA311157.html

RCbuzz

Very Active Member

- Messages

- 2,906

- Reaction score

- 5,113

- Arrma RC's

- Granite

- Kraton 8S

- Kraton 6s

- Mojave EXB

- Senton 3s

This feels like a side effect of having the updated shorter rear spline on the input gear. I believe they did this to accommodate the plastic nut to better hold the slipper assembly tight... I have not had this happen yet on my older 3S rigs and also have not had too much slipper trouble after getting the Loctite to set correctly in the slipper screw/threads.

I feel like they should have kept the spline longer or used a stronger metal for the slipper metal bits... One step forward.. Not sure how many steps backwards.

One thing is for sure, I wish I had stocked up on the old input gears with the longer splines back when Jenny's had them.

I feel like they should have kept the spline longer or used a stronger metal for the slipper metal bits... One step forward.. Not sure how many steps backwards.

One thing is for sure, I wish I had stocked up on the old input gears with the longer splines back when Jenny's had them.

Velodromed

Snatching defeat from the jaws of victory!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 7,758

- Reaction score

- 13,925

- Location

- San Antonio, TX

- Arrma RC's

- BigRock 4x4

- Granite

- Kraton 6s

- Kraton 4s

- Notorious

- Outcast 4s

- Vorteks

- Voltage

- Infraction 4x4

I’ve never had issues with the driveshaft connection part of the hub. It’s always where it connects to the rear differential that has issues. I believe that part of the hub is the same for all models. If I’m wrong please let me know so I can go find itThis feels like a side effect of having the updated shorter rear spline on the input gear. I believe they did this to accommodate the plastic nut to better hold the slipper assembly tight... I have not had this happen yet on my older 3S rigs and also have not had too much slipper trouble after getting the Loctite to set correctly in the slipper screw/threads.

I feel like they should have kept the spline longer or used a stronger metal for the slipper metal bits... One step forward.. Not sure how many steps backwards.

One thing is for sure, I wish I had stocked up on the old input gears with the longer splines back when Jenny's had them.

RCbuzz

Very Active Member

- Messages

- 2,906

- Reaction score

- 5,113

- Arrma RC's

- Granite

- Kraton 8S

- Kraton 6s

- Mojave EXB

- Senton 3s

So far, I have not had issues with the center driveshaft connection either.

At the thread below someone had troubles installing their power module after a new slipper, turns out the old diff input gear is longer. You have to scrap the plastic nut in the V3 slipper for it to work.

Seems like quite a bit more contact area with the longer input gear. Especially at that point where you see very high torque to the rear wheels.

https://www.arrmaforum.com/threads/power-module-doesn't-fit-correctly.44345/post-618380

At the thread below someone had troubles installing their power module after a new slipper, turns out the old diff input gear is longer. You have to scrap the plastic nut in the V3 slipper for it to work.

Seems like quite a bit more contact area with the longer input gear. Especially at that point where you see very high torque to the rear wheels.

https://www.arrmaforum.com/threads/power-module-doesn't-fit-correctly.44345/post-618380

Velodromed

Snatching defeat from the jaws of victory!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 7,758

- Reaction score

- 13,925

- Location

- San Antonio, TX

- Arrma RC's

- BigRock 4x4

- Granite

- Kraton 6s

- Kraton 4s

- Notorious

- Outcast 4s

- Vorteks

- Voltage

- Infraction 4x4

Huh! Interesting… I must find one for grins and check it out.So far, I have not had issues with the center driveshaft connection either.

At the thread below someone had troubles installing their power module after a new slipper, turns out the old diff input gear is longer. You have to scrap the plastic nut in the V3 slipper for it to work.

Seems like quite a bit more contact area with the longer input gear. Especially at that point where you see very high torque to the rear wheels.

https://www.arrmaforum.com/threads/power-module-doesn't-fit-correctly.44345/post-618380

- Messages

- 2,477

- Reaction score

- 2,586

- Arrma RC's

- Granite

This feels like a side effect of having the updated shorter rear spline on the input gear. I believe they did this to accommodate the plastic nut to better hold the slipper assembly tight... I have not had this happen yet on my older 3S rigs and also have not had too much slipper trouble after getting the Loctite to set correctly in the slipper screw/threads.

I feel like they should have kept the spline longer or used a stronger metal for the slipper metal bits... One step forward.. Not sure how many steps backwards.

One thing is for sure, I wish I had stocked up on the old input gears with the longer splines back when Jenny's had them.

I thought so as well, because I never had the problem with the old input gear. But others have said they had the same problem with the old input gear.

That's what I'm using right now. It most definitely helps, but I already have a small crack again. If the new metal sleeve from Arrma doesn't work any better, Oktay makes a slipper housing upgrade. I think it's 7075 aluminum. But it's a German company, so shipping to the U.S. is going to be very pricey.Or just slip on an inner race from an old bearing.

Similar threads

- Replies

- 4

- Views

- 360