Paul_c

Active Member

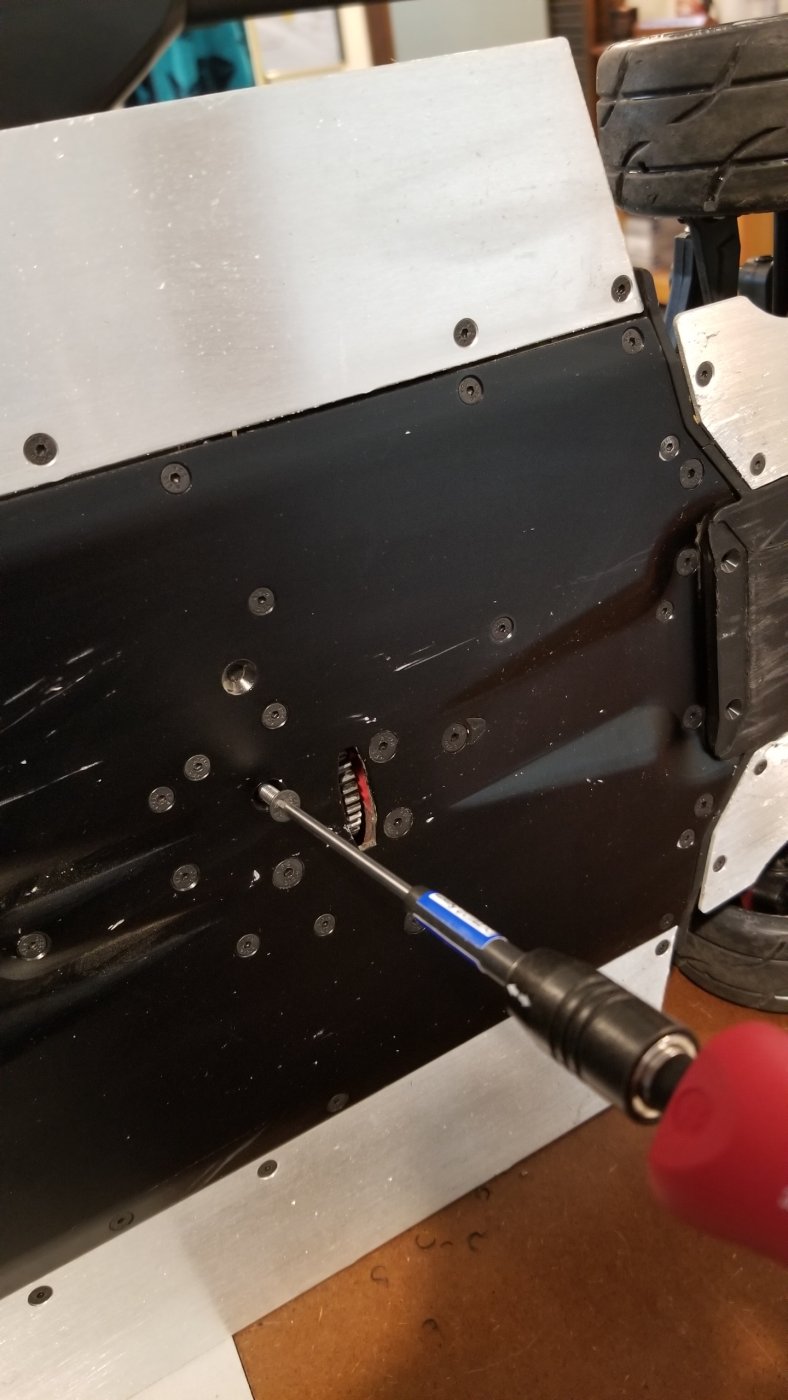

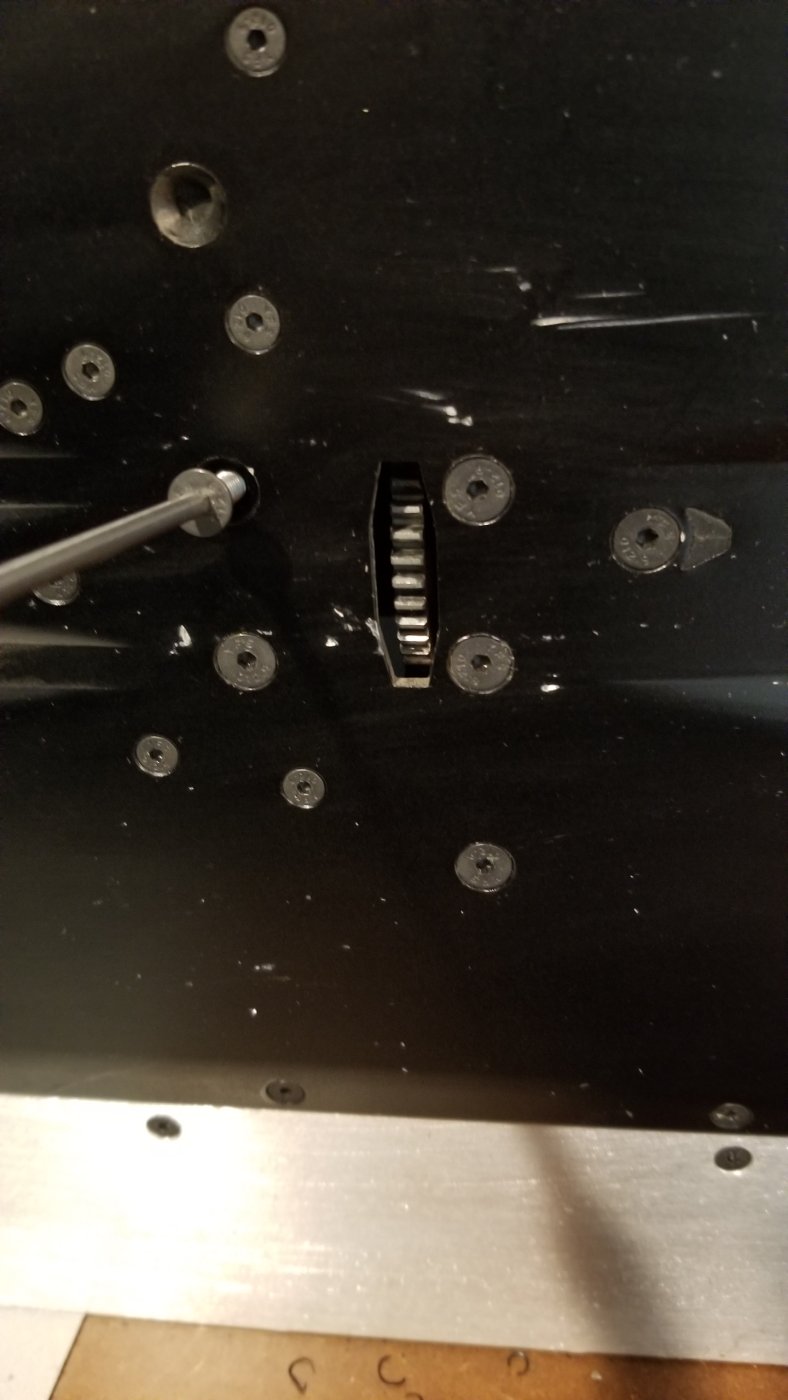

Newbie RC guy here. I went to tighten down all screws, and this one underneath just spins. It is one of four 2.5mm screws (holds the center diff?).

Anyway, should I drill this out and tap for a bigger screw? Thanks!

Anyway, should I drill this out and tap for a bigger screw? Thanks!