RC-Dude

Very Active Member

- Messages

- 1,588

- Reaction score

- 3,318

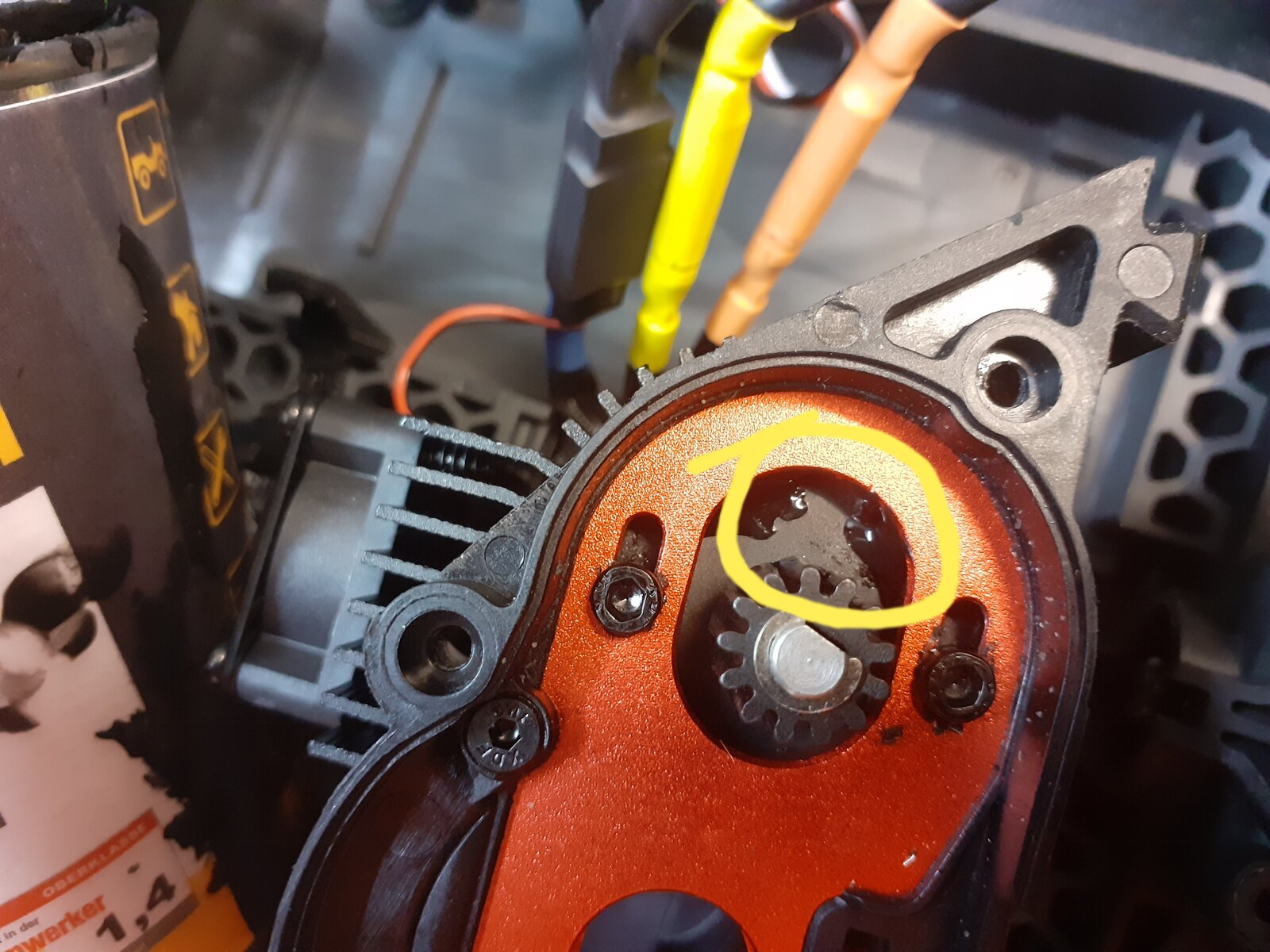

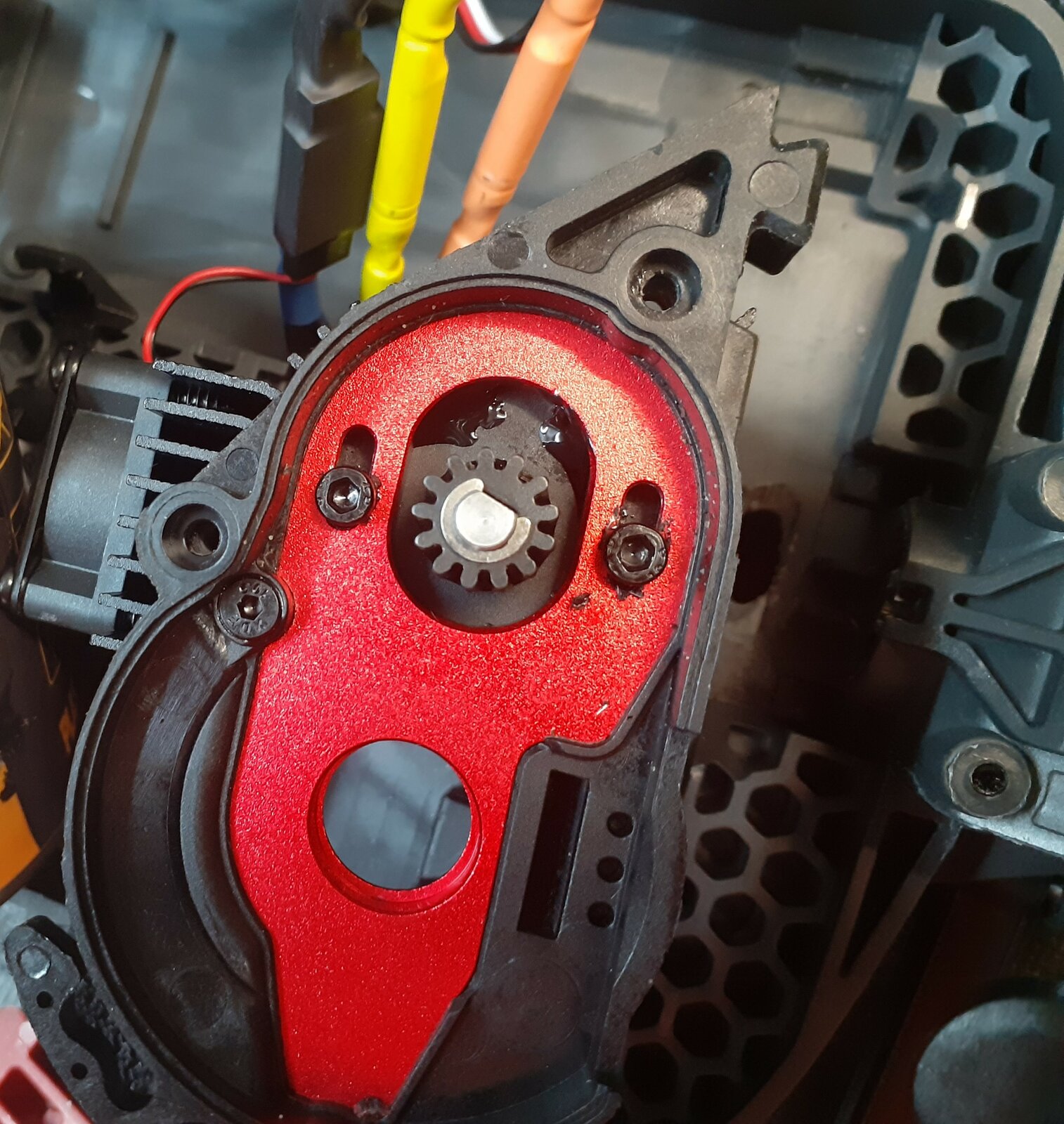

Not sure if someone has posted something similar.

I ruined a new Arrma Typhons 3s brushless motor within two or three batteries because fine dust came right into the motor blocking the coil and bearings.

So you need to put some glue (soft so it can be removed when you change pinion), rubber etc on the open holes of the brushless motor. Depending on the pinion you use the holes are sometimes more open, sometimes more closed. Those threaded holes need to be sealed. The openings are smaller with the stock pinion.

Here some pictures:

I

I ruined a new Arrma Typhons 3s brushless motor within two or three batteries because fine dust came right into the motor blocking the coil and bearings.

So you need to put some glue (soft so it can be removed when you change pinion), rubber etc on the open holes of the brushless motor. Depending on the pinion you use the holes are sometimes more open, sometimes more closed. Those threaded holes need to be sealed. The openings are smaller with the stock pinion.

Here some pictures:

I

Last edited: