- Messages

- 6,754

- Reaction score

- 12,426

- Location

- ST.LOUIS

- Arrma RC's

- BigRock 4x4

- Mojave

- Notorious

- Senton 6s

- Senton 3s

- Typhon 6s

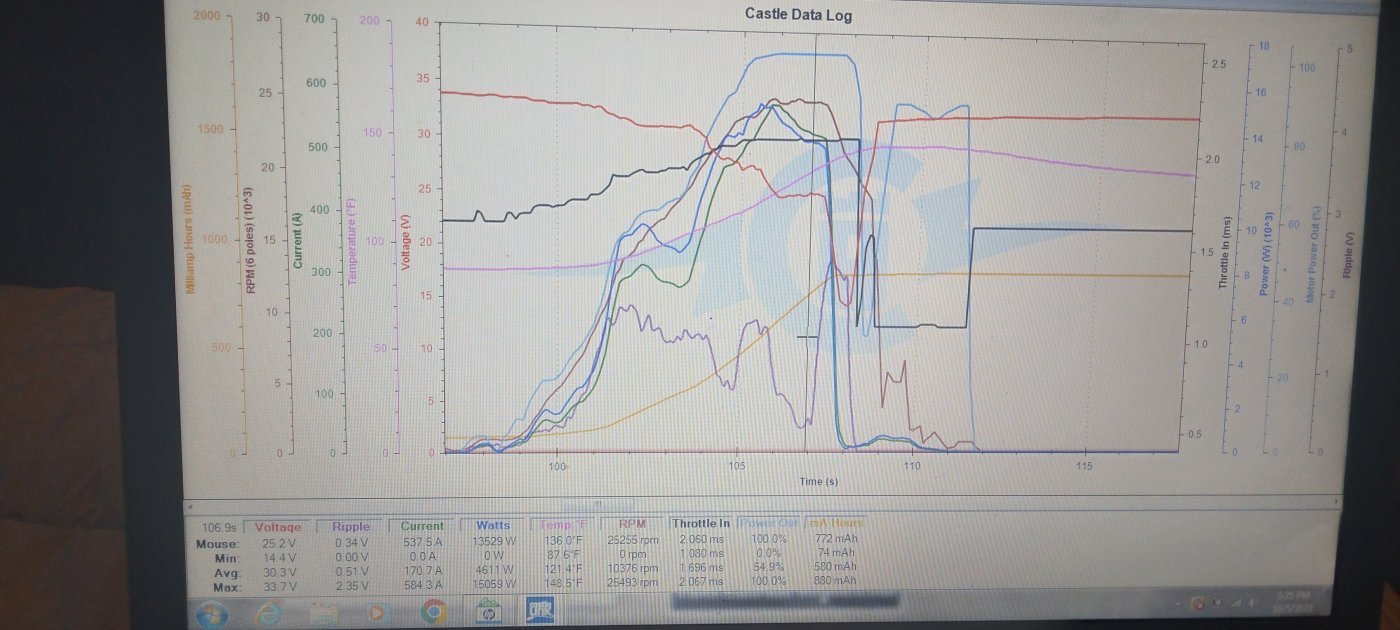

Everybody thinks ya need high kv,rpms to make power,not so much the case with electric motors.combustion motors need rpms to make power...high kv,rpms take more energy, amps to spin up..high rpms just make car harder to control..56mm torque puts power down controllablely...here's 1270kv 8s log putting out 20hp or 15,000w an only at 25,000rpms....no need to be close to 50,000rpm with them...imo low rpm torque is way better than high rpm horsepower.esc an packs will agree

This is run from this log..this is 25,000rpms.......CRAZY HUH.sounds like 80,000...lol.killed esc on this run

log..this is 25,000rpms.......CRAZY HUH.sounds like 80,000...lol.killed esc on this run

This is run from this

Last edited: