decline225

Member

- Messages

- 46

- Reaction score

- 41

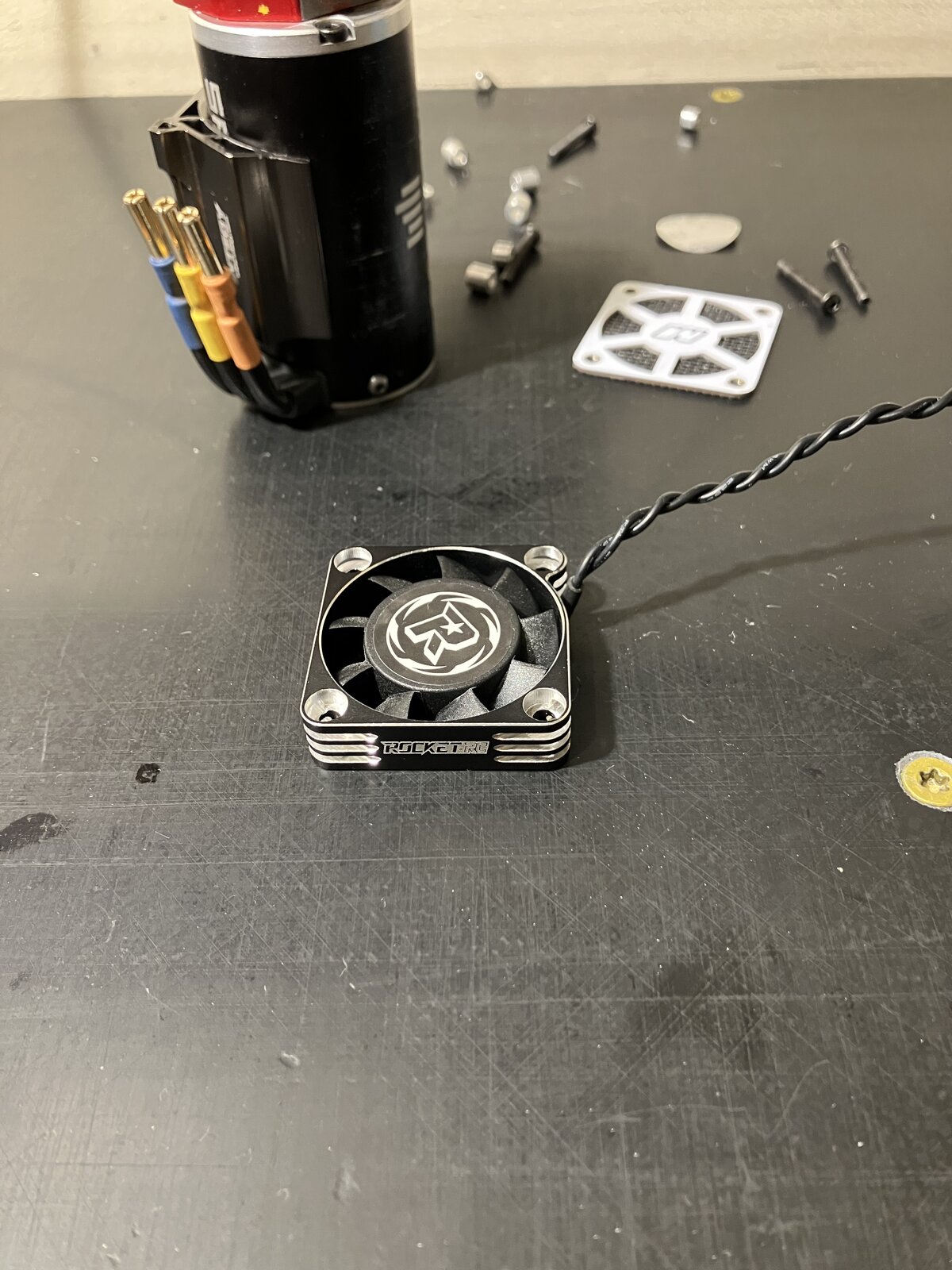

This in my opinion is the best/correct way to keep fans from breaking due to hard landings (or shocking). This fix however will do nothing for fans breaking due to debri. I’ve done this for years and have had none break due to shocking. Most people have figured out that hard landings or impacts can cause the fan frame and or blades to break which is due to the fan compressing so fast and hard when making contact with the frame of the fan and having no dampening. I’ve seen fixes usually consisting of rubber padding fixed between the fan frame and esc/motor heatsink(or mount) which works great but you can’t tighten the screws down very much or it defeats the whole idea and it’s not truly dampening what parts are actually hitting each other which is the fan itself hitting the frame of the fan, more specifically where bottom of the fan shaft is located which is just hard plastic sometimes with a nylon washer.

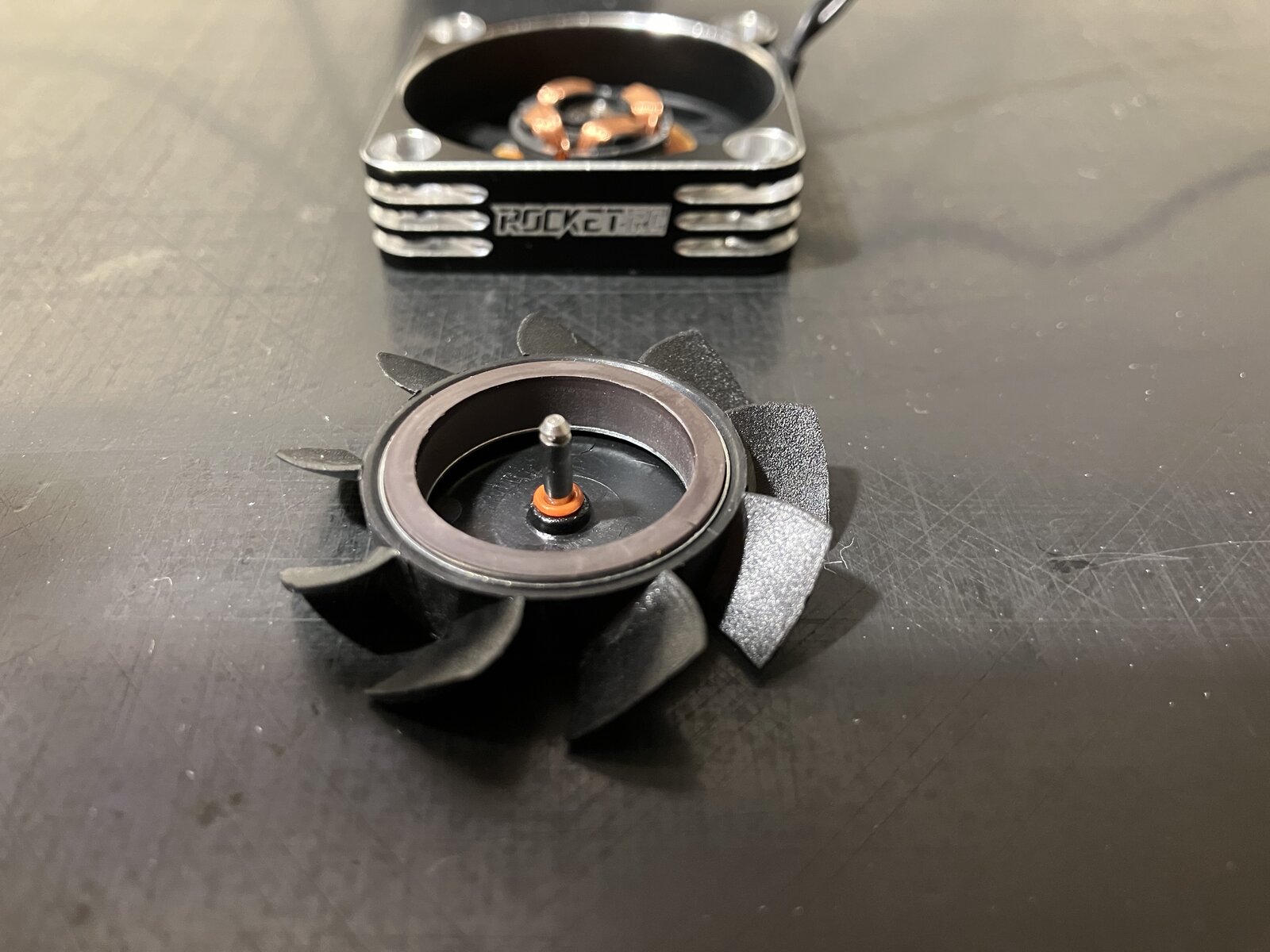

It’s this spot that gets “shocked” when impacted by a hard landing ect and wants to break parts. To mitigate this is to make sure this area never gets shocked. Dampening this specific area is again in my opinion the true fix. I’ve found running a micro o-ring there creates more than enough dampening for the fan to not break. I found this out wondering why my factory Mojave blx spectrum fan never seemed to break with really hard landings. I took it apart one day and found there was a very small spring in the area I’m referring to, which was cushioning the fan. I came across another fan from eBay around the same time and when the blades finally broke via a rock I took it apart and found a tiny oring in the same spot as the spectrum spring. So both of these fans lasted so long and didn’t break due to hard impacts because they were cushioned with either a spring or an O-ring. That’s pretty much it! But know you can tighten the fan screws down tight or not have to use thread locker every time.

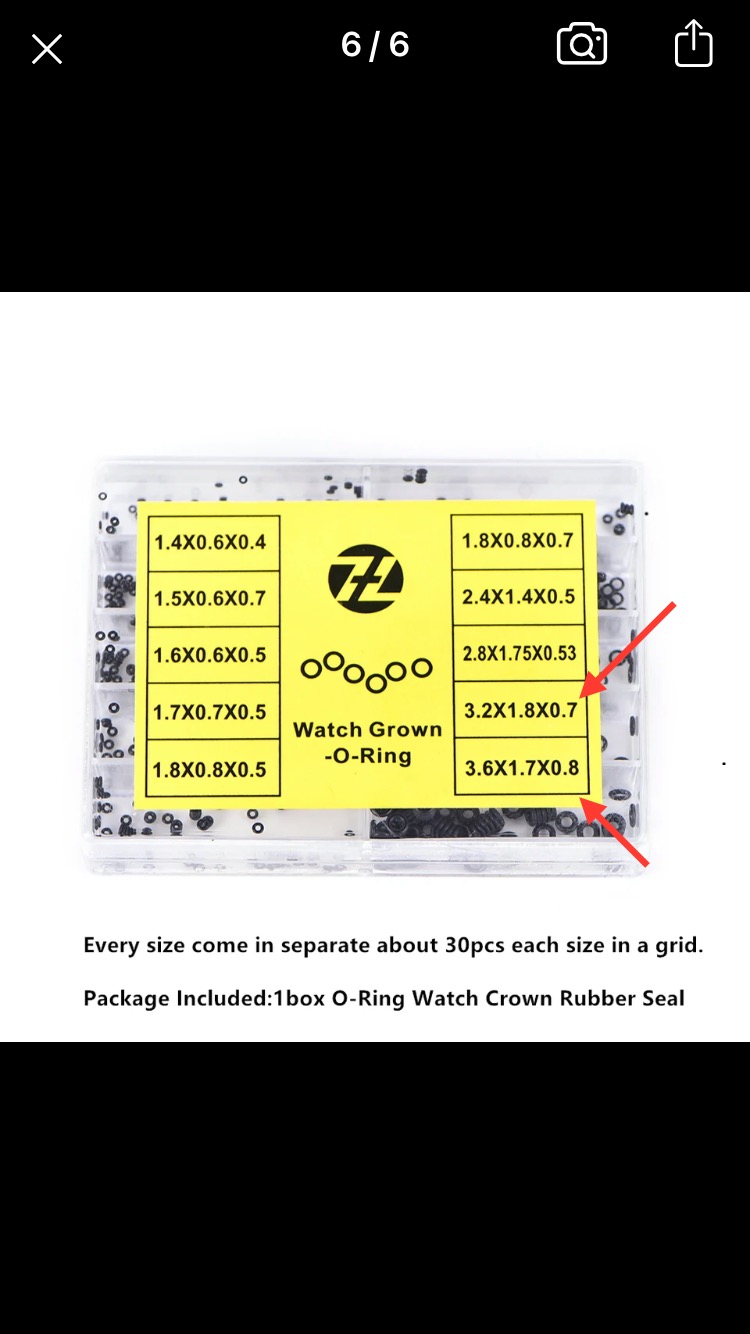

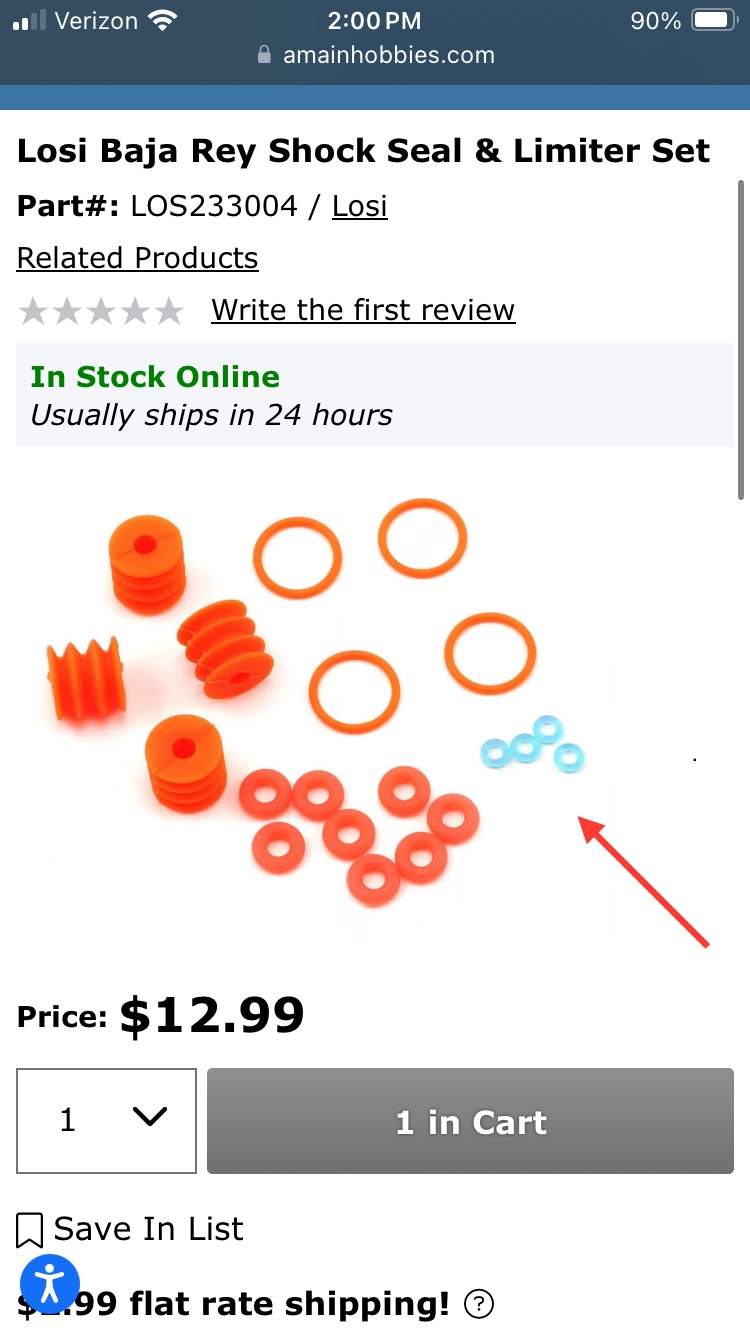

The most important thing with this modification is to make sure that the fan still spins freely and doesn’t have any drag because of the tolerance being too tight. Not all fans are the same, my rocket fans have a nylon washer which I had to remove and replaced with an o-ring which actually came from one of my old fans. I prefer the o-ring to the spring. The only issue being it’s really difficult to find orings with a small enough cross section being around 0.7mm. 1mm is usually too big causing it to bind. Watch o ring kits contain 2 useable sizes aswell as the small clear cap bleeder orings in the losi Baja Rey shock kit(on right side in photo). Hopefully a few of you find this information good to know at least.

It’s this spot that gets “shocked” when impacted by a hard landing ect and wants to break parts. To mitigate this is to make sure this area never gets shocked. Dampening this specific area is again in my opinion the true fix. I’ve found running a micro o-ring there creates more than enough dampening for the fan to not break. I found this out wondering why my factory Mojave blx spectrum fan never seemed to break with really hard landings. I took it apart one day and found there was a very small spring in the area I’m referring to, which was cushioning the fan. I came across another fan from eBay around the same time and when the blades finally broke via a rock I took it apart and found a tiny oring in the same spot as the spectrum spring. So both of these fans lasted so long and didn’t break due to hard impacts because they were cushioned with either a spring or an O-ring. That’s pretty much it! But know you can tighten the fan screws down tight or not have to use thread locker every time.

The most important thing with this modification is to make sure that the fan still spins freely and doesn’t have any drag because of the tolerance being too tight. Not all fans are the same, my rocket fans have a nylon washer which I had to remove and replaced with an o-ring which actually came from one of my old fans. I prefer the o-ring to the spring. The only issue being it’s really difficult to find orings with a small enough cross section being around 0.7mm. 1mm is usually too big causing it to bind. Watch o ring kits contain 2 useable sizes aswell as the small clear cap bleeder orings in the losi Baja Rey shock kit(on right side in photo). Hopefully a few of you find this information good to know at least.