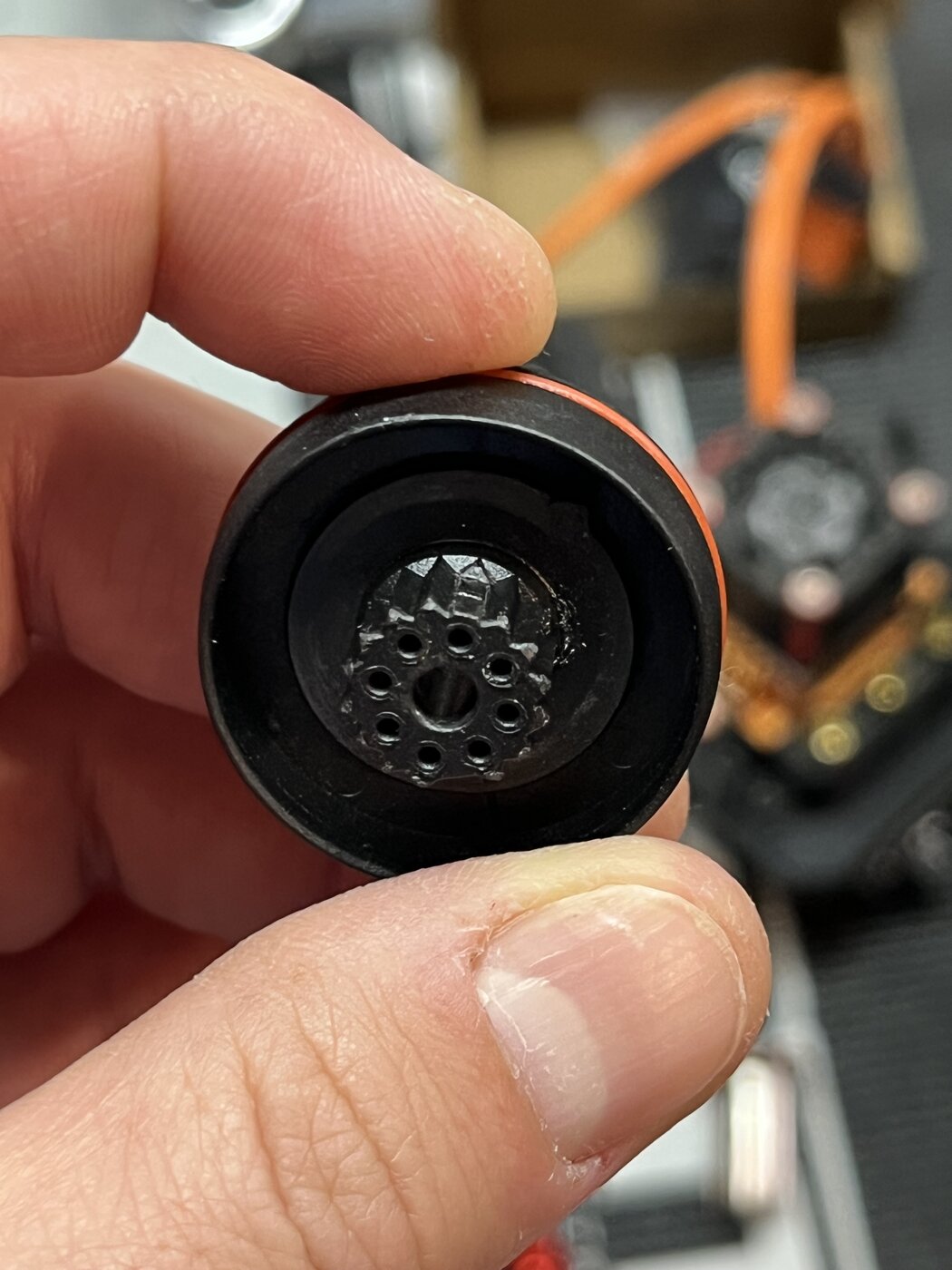

Hi everyone. In the middle of installing the Primal PM13130 and ran into a little issue. I think I stripped a tooth when I pressed the saver onto the plastic bit with my vice. Im not sure how this happened since I thought it was keyed properly before closing a vice on it to seat it properly. I guess not

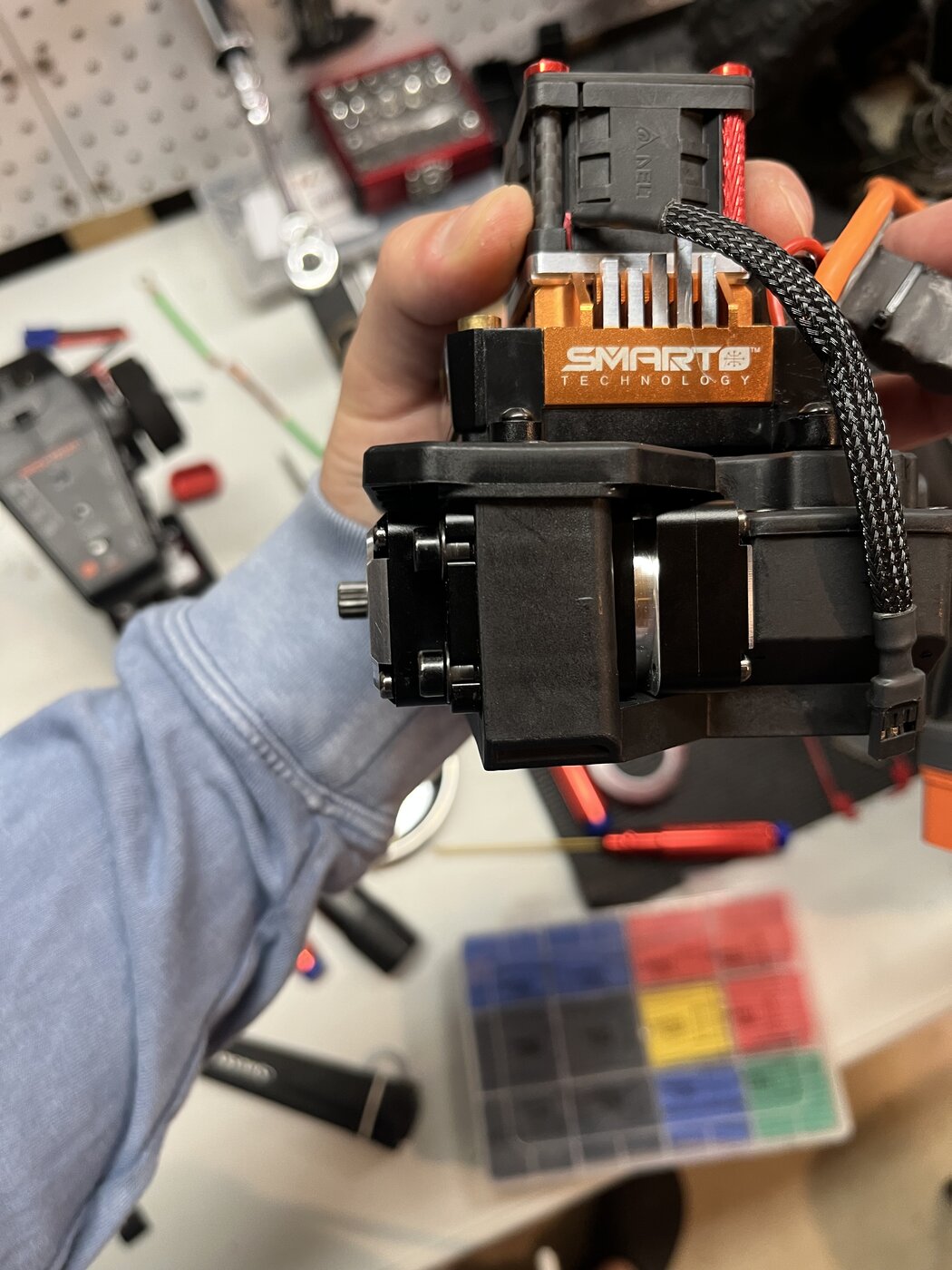

During the install the servo saver was slowly backing out, until the red o-ring was completely exposed. I couldn’t get the assembly (esc & electronics box) to sit properly in the car to line up the holes. I disassembled the saver and found this tooth gone which I think pushed the saver forward, pushing the esc/electronics box back, yadda yadda. Please know I tried the servo once to make sure I had power and didn’t steer very hard, so I’m confident the vice did this.

my question is, how do y’all press these things together?! It’s impossible for me to overcome the springs enough to seat this.

Ordering hot racing since that seems to be the only upgrade option.

p.s. this servo seems to be on the XL side. Meaning, I think I may have to shave some plastic from the retention box to free up even more space :/

During the install the servo saver was slowly backing out, until the red o-ring was completely exposed. I couldn’t get the assembly (esc & electronics box) to sit properly in the car to line up the holes. I disassembled the saver and found this tooth gone which I think pushed the saver forward, pushing the esc/electronics box back, yadda yadda. Please know I tried the servo once to make sure I had power and didn’t steer very hard, so I’m confident the vice did this.

my question is, how do y’all press these things together?! It’s impossible for me to overcome the springs enough to seat this.

Ordering hot racing since that seems to be the only upgrade option.

p.s. this servo seems to be on the XL side. Meaning, I think I may have to shave some plastic from the retention box to free up even more space :/