Velodromed

Snatching defeat from the jaws of victory!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 7,758

- Reaction score

- 13,924

- Location

- San Antonio, TX

- Arrma RC's

- BigRock 4x4

- Granite

- Kraton 6s

- Kraton 4s

- Notorious

- Outcast 4s

- Vorteks

- Voltage

- Infraction 4x4

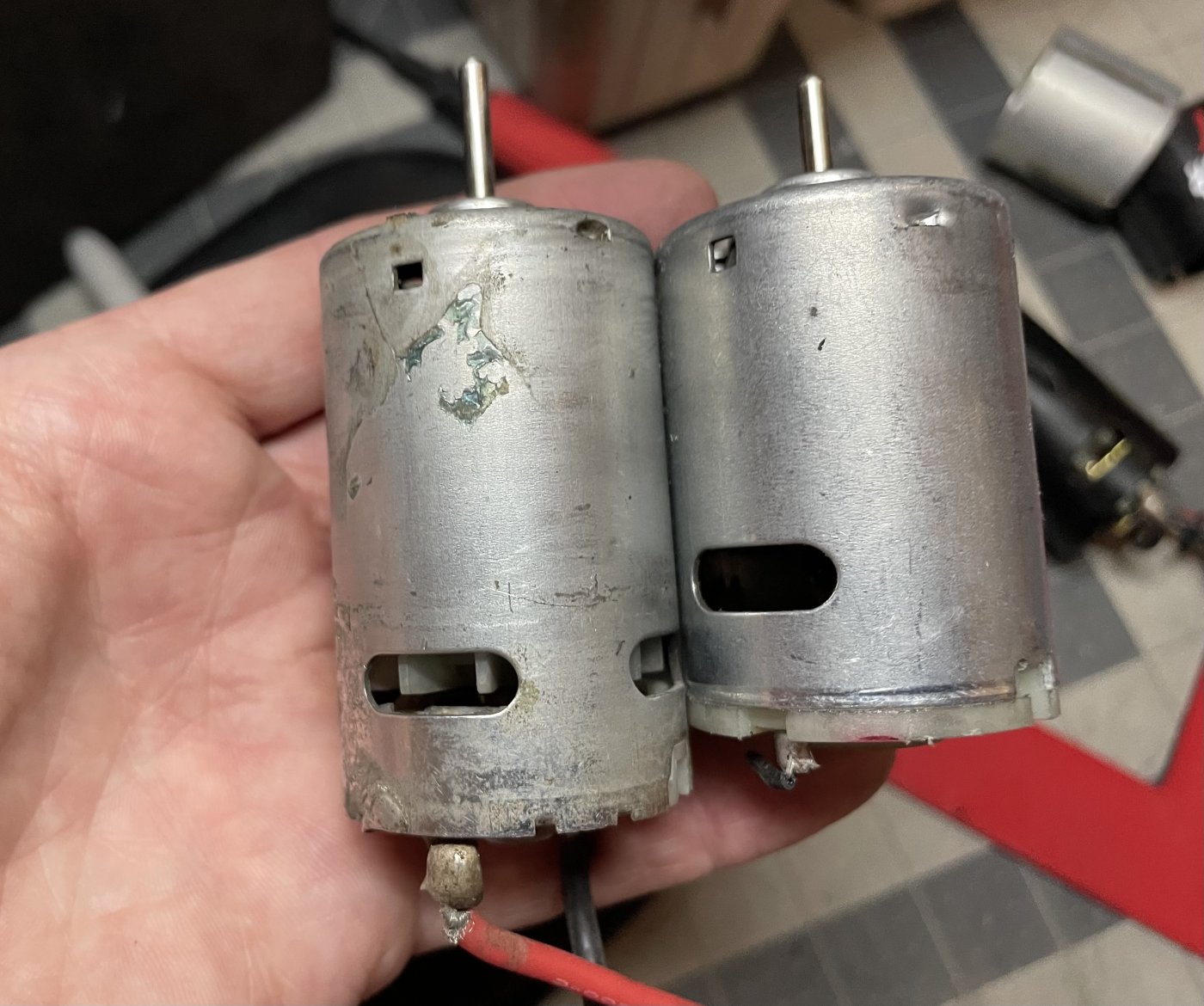

My other hobby is rock tumbling and jewlery making. I recently picked up this super cheap rock tumbler (for tumbling rocks) figuring I’d swap in a new motor when the stock one died, which looks like a brushed 540. It died, so I swapped in a motor off an old voltage, a brushed 550. It wouldn’t work much at all so I tried another 550 motor. No luck, it’s getting power but acts feeble and won’t turn the rollers. So I’m asking here since my electrical skills are rudimentary at best…what am I doing wrong?