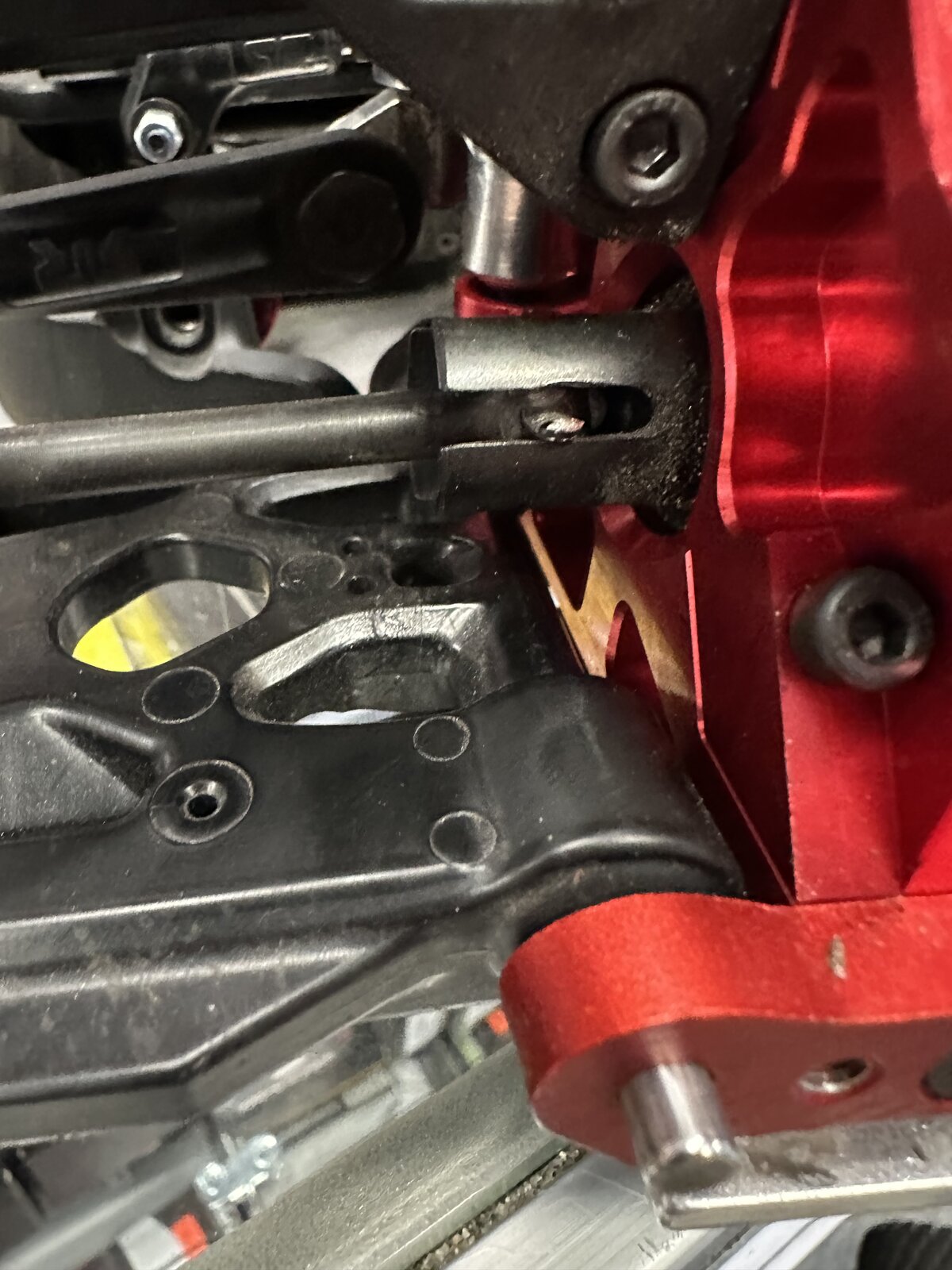

Hello guys I am really getting frustrated since I changed 3 sets of outdrives my kraton has 800 kv castle and mamba xlx 2 running 39/34 any solution for this problem because nothing has worked changed fluid to 2 mil and ear plugs still ripping them like nothing ran the m2c best one and killed it first run

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kraton Kraton 8s out drive pins just keep breaking changed to m2c and still breaking them

- Thread starter Hassan77

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

- Messages

- 8,290

- Reaction score

- 17,356

- Arrma RC's

- Felony

- Fireteam

- Infraction

- Limitless

- Kraton 8S

- Kraton EXB

- Kraton 4s

- Mojave EXB

- Notorious

- Outcast 8s

- Outcast EXB

- Talion EXB

- Typhon 3s

- Typhon 6s

- Typhon TLR

Hello guys I am really getting frustrated since I changed 3 sets of outdrives my kraton has 800 kv castle and mamba xlx 2 running 39/34 any solution for this problem because nothing has worked changed fluid to 2 mil and ear plugs still ripping them like nothing ran the m2c best one and killed it first run

View attachment 355343

View attachment 355345

View attachment 355346

- Messages

- 2,151

- Reaction score

- 4,669

- Location

- God’s Country

- Arrma RC's

- BigRock

- Fireteam

- Granite Grom

- Infraction

- Mojave

- Notorious

- Typhon 6s

- Typhon TLR

Order some S7 or A2 tool steel pins and cut them to length, much tougher alloy than off-the-shelf rod.

Last edited:

easi millz

Fairly New Member

- Messages

- 23

- Reaction score

- 42

easi millz

Fairly New Member

- Messages

- 23

- Reaction score

- 42

What do you have your diff oils at? Possibly tune the rig down a bitI’m not bashing hard at all baby my rig and it breaks first run since I changed to 800 kv 3 sets of out drives evertime first run 5 min in broken too much torque I don’t know

- Thread starter

- #8

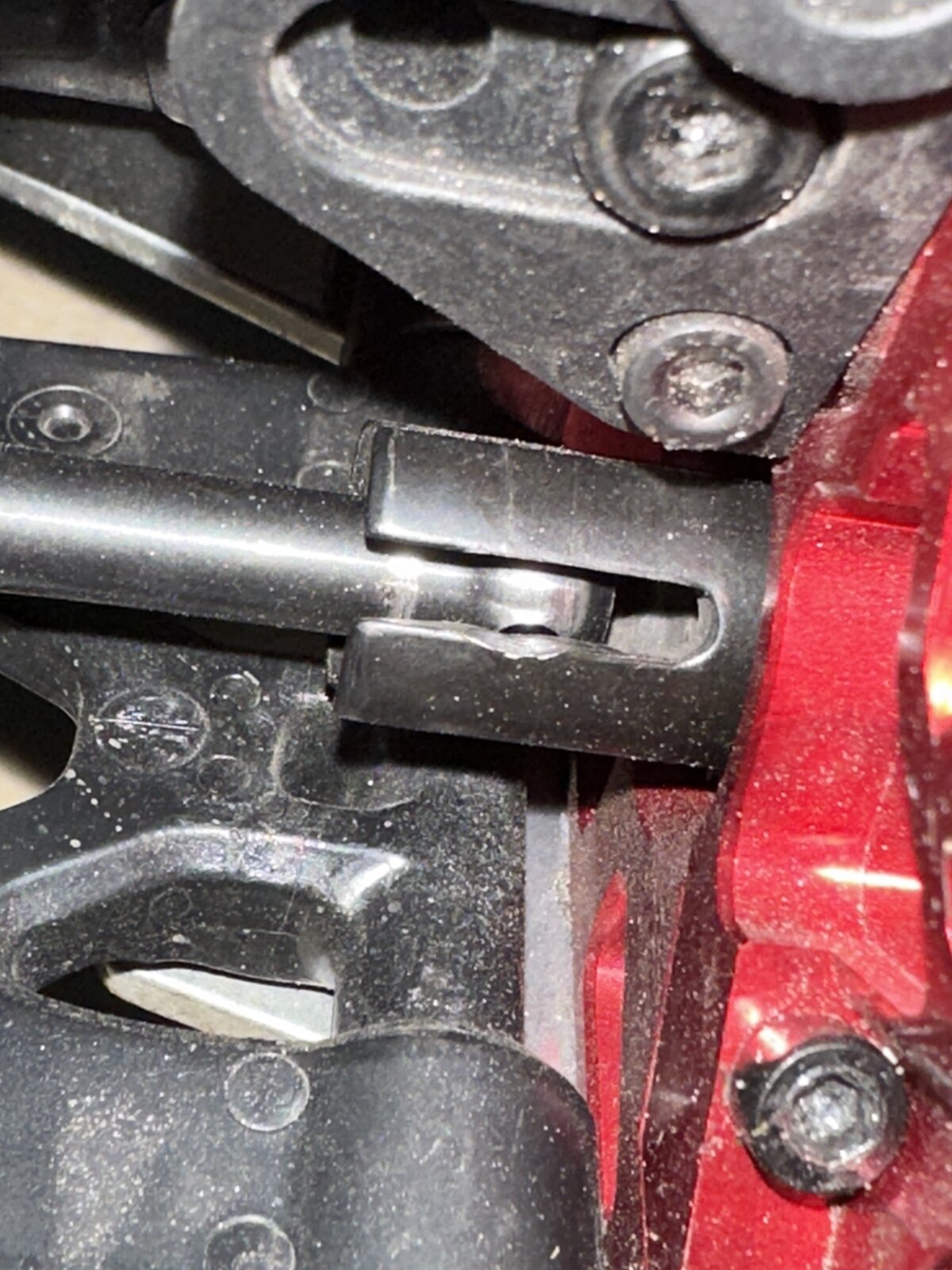

These are the ones I got a and broke just now

Mil front 2 mil back with ear plugsWhat do you have your diff oils at? Possibly tune the rig down a bit

- Messages

- 8,290

- Reaction score

- 17,356

- Arrma RC's

- Felony

- Fireteam

- Infraction

- Limitless

- Kraton 8S

- Kraton EXB

- Kraton 4s

- Mojave EXB

- Notorious

- Outcast 8s

- Outcast EXB

- Talion EXB

- Typhon 3s

- Typhon 6s

- Typhon TLR

These are the ones I got a and broke just now

Mil front 2 mil back with ear plugs

This is really important and it will keep happening until you address the droop or shock travel. Personally I put nylon washers on my rear shock shafts to limit travel and have never had it happen again. Not even on my 12s kraton.

I use these but you can use whatever works.

https://a.co/d/dmyexft

- Thread starter

- #10

I have m2c shock pistons that I’m gonna install would it work the sameView attachment 355358

This is really important and it will keep happening until you address the droop or shock travel. Personally I put nylon washers on my rear shock shafts to limit travel and have never had it happen again. Not even on my 12s kraton.

I use these but you can use whatever works.

https://a.co/d/dmyexft

- Messages

- 8,290

- Reaction score

- 17,356

- Arrma RC's

- Felony

- Fireteam

- Infraction

- Limitless

- Kraton 8S

- Kraton EXB

- Kraton 4s

- Mojave EXB

- Notorious

- Outcast 8s

- Outcast EXB

- Talion EXB

- Typhon 3s

- Typhon 6s

- Typhon TLR

no sir, personally I think the easiest thing you could do is just buy some nylon washers like I did and put them on the shock shaft. Takes like 5 minutes to do both shocks. There are multiple ways to skin a cat though!I have m2c shock pistons that I’m gonna install would it work the same

https://www.amazon.com/QTEATAK-Assortment-Electrical-Connections-Commercial/dp/B092V26GQG

RCbuzz

Very Active Member

- Messages

- 2,902

- Reaction score

- 5,106

- Arrma RC's

- Granite

- Kraton 8S

- Kraton 6s

- Mojave EXB

- Senton 3s

Do you typically just add washers inside the shocks or on the outside as well to reduce max compression? Recall how much spacing?no sir, personally I think the easiest thing you could do is just buy some nylon washers like I did and put them on the shock shaft. Takes like 5 minutes to do both shocks. There are multiple ways to skin a cat though!

https://www.amazon.com/QTEATAK-Assortment-Electrical-Connections-Commercial/dp/B092V26GQG

- Messages

- 8,290

- Reaction score

- 17,356

- Arrma RC's

- Felony

- Fireteam

- Infraction

- Limitless

- Kraton 8S

- Kraton EXB

- Kraton 4s

- Mojave EXB

- Notorious

- Outcast 8s

- Outcast EXB

- Talion EXB

- Typhon 3s

- Typhon 6s

- Typhon TLR

I only added maybe 7 to 9 to the outside and have never had a problem since.Do you typically just add washers inside the shock or on the outside as well to reduce max compression? Recall how much spacing?

RCbuzz

Very Active Member

- Messages

- 2,902

- Reaction score

- 5,106

- Arrma RC's

- Granite

- Kraton 8S

- Kraton 6s

- Mojave EXB

- Senton 3s

Very nice! So that just reduces max compression on a landing right?I only added maybe 7 to 9 to the outside and have never had a problem since.

Rely on the droop screws for the max extension? I have wanted to try washers/tubing on the internal of the 8S shocks as well to see how that fares (instead of using droop screws). I tried that on a 3S rig and it worked well, basically it was slightly over extending causing the drive shafts to shred. Just used a little nitro fuel tubing.

- Messages

- 8,290

- Reaction score

- 17,356

- Arrma RC's

- Felony

- Fireteam

- Infraction

- Limitless

- Kraton 8S

- Kraton EXB

- Kraton 4s

- Mojave EXB

- Notorious

- Outcast 8s

- Outcast EXB

- Talion EXB

- Typhon 3s

- Typhon 6s

- Typhon TLR

Very nice! So that just reduces max compression on a landing right?

Rely on the droop screws for the max extension? I have wanted to try washers/tubing on the internal of the 8S shocks as well to see how that fares (instead of using droop screws). I tried that on a 3S rig and it worked well, basically it was slightly over extending causing the drive shafts to shred. Just used a little nitro fuel tubing.

Yea on landing, also when you do wheelies. I've snapped a few dog bones on outdrive side from doing wheelies. I never worried about max extension tbh so i don't have anything for it. Thankfully it seems like I haven't needed it.

- Messages

- 873

- Reaction score

- 1,808

- Location

- SE MICHIGAN

- Arrma RC's

- Granite

- Infraction

- Outcast 4s

- Outcast 6s

- Outcast 8s

- Typhon 3s

- Typhon 6s

Glad you clarified this, I was under the assumption you were putting them on the inside to limit extension. I did same thing on my Xmaxx, except I used fuel injector o-rings from a real car (I'm a 1:1 mechanic so I had them laying around lol). I would normally think the M2C droop screws would be enough to limit extension, but I'm not so sure on the 8s stuff, it's alot bigger and heavier than the 6s rigs, and I could see the potential for the little ear on the chassis where the droop screws come in contact with bending, or the control arm flexing so much that it negates the droop screw from doing its job.. I think I'm going to try 6mm stainless washers on the inside to limit extension, and my injector o-ring idea with a steel washer on either side on the outside to limit compression, and see how that treats meYea on landing, also when you do wheelies. I've snapped a few dog bones on outdrive side from doing wheelies. I never worried about max extension tbh so i don't have anything for it. Thankfully it seems like I haven't needed it.

Hey, do you mind posting a pic of what those look like installed....for dummies (me)? I managed to break one of the rear shafts I got from Vitavon - so tired of this happening. ThanksI only added maybe 7 to 9 to the outside and have never had a problem since.

- Messages

- 1,777

- Reaction score

- 5,632

- Arrma RC's

- Notorious

- Talion

- Typhon 6s

Sorry to sidetrack from 8s but wondering if washers or o-rings on the shock shaft outside keep 6s rig dogbones from popping out? I removed the spacer between the top front arm and pivot ball, but if limiting shock compression works just as good I'd prefer being able to use the spacers to adjust camber.

- Messages

- 8,290

- Reaction score

- 17,356

- Arrma RC's

- Felony

- Fireteam

- Infraction

- Limitless

- Kraton 8S

- Kraton EXB

- Kraton 4s

- Mojave EXB

- Notorious

- Outcast 8s

- Outcast EXB

- Talion EXB

- Typhon 3s

- Typhon 6s

- Typhon TLR

Hey, do you mind posting a pic of what those look like installed....for dummies (me)? I managed to break one of the rear shafts I got from Vitavon - so tired of this happening. Thanks

yup! that was the original reason I bought the washers. Was a benefit they came with so many different sizes and worked on 8s rigs too haha.Sorry to sidetrack from 8s but wondering if washers or o-rings on the shock shaft outside keep 6s rig dogbones from popping out? I removed the spacer between the top front arm and pivot ball, but if limiting shock compression works just as good I'd prefer being able to use the spacers to adjust camber.

Awesome, thanks a million.View attachment 357625

yup! that was the original reason I bought the washers. Was a benefit they came with so many different sizes and worked on 8s rigs too haha.

I think this is a necessary mod - but I don't understand why..lol. Isn't shock compression already limited by chassis slamming the ground?