Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Big Rock Mesh in power mod

- Thread starter Jimmer101

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

Yes, your motor mount is bent.

Yep, bent mount. Also throw a flat washer underneath the head of the screw before you reattach the motor as you don't want to divot the aluminum from the screw head - makes setting the mesh harder.

Velodromed

Snatching defeat from the jaws of victory!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 7,758

- Reaction score

- 13,925

- Location

- San Antonio, TX

- Arrma RC's

- BigRock 4x4

- Granite

- Kraton 6s

- Kraton 4s

- Notorious

- Outcast 4s

- Vorteks

- Voltage

- Infraction 4x4

Yeah you bent the hell out of it. Try to get the updated thicker stock motor mount and put a 36mm o-ring around the end of the motor can.Hi everyone

My power module came loose so I'm about to tighten up.

However it looks like the red metal but with ADJ mesh on it has bent a bit?

Presumably it's supposed to be flush?

Help !

Thank you so much

Simon

Is it

View attachment 212482

View attachment 212483

Or even better get a m2c mount/brace, if you have $75 to drop on it.

- Messages

- 6,754

- Reaction score

- 12,426

- Location

- ST.LOUIS

- Arrma RC's

- BigRock 4x4

- Mojave

- Notorious

- Senton 6s

- Senton 3s

- Typhon 6s

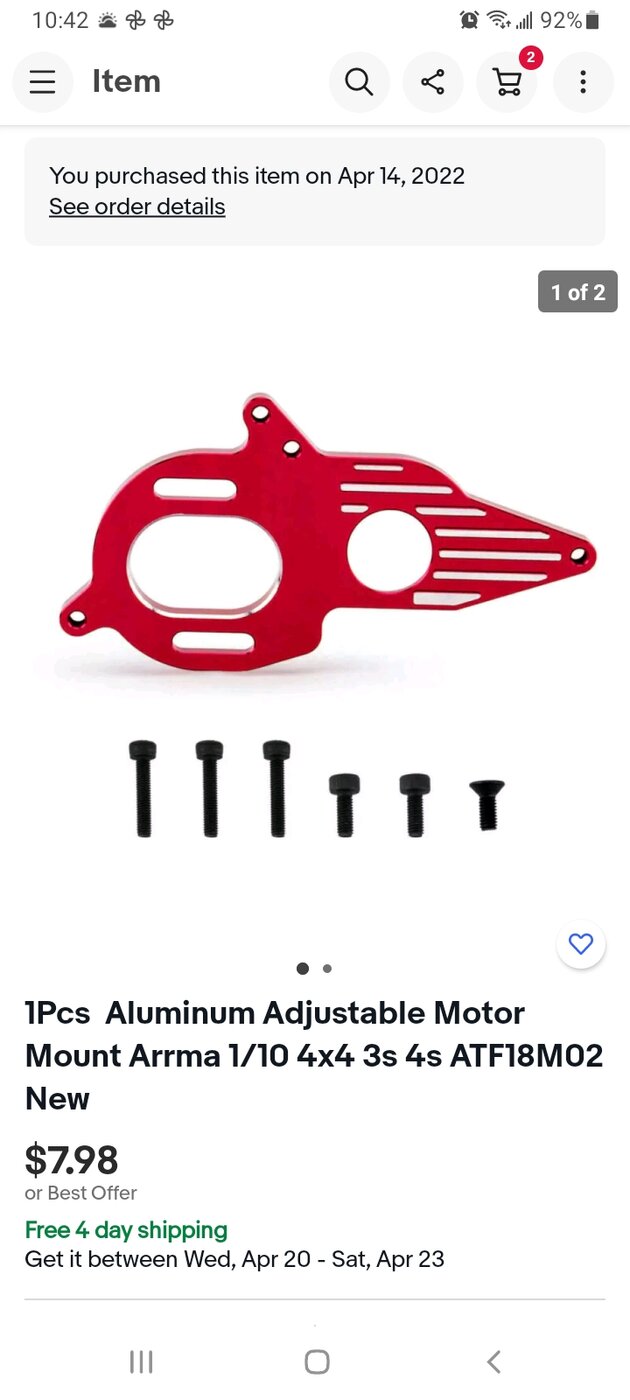

Order a new one..can beat that one flat an keep going.heres my module..kept cutting till I could fit the big speed gears in it .ran 112mph yesterday on 5s..I just got this mount off ebay.

Velodromed

Snatching defeat from the jaws of victory!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 7,758

- Reaction score

- 13,925

- Location

- San Antonio, TX

- Arrma RC's

- BigRock 4x4

- Granite

- Kraton 6s

- Kraton 4s

- Notorious

- Outcast 4s

- Vorteks

- Voltage

- Infraction 4x4

That mount looks thicker then the hot racing and old stock mount. Got a set of calipers? I’m curious…Order a new one..can beat that one flat an keep going.heres my module..kept cutting till I could fit the big speed gears in it .ran 112mph yesterday on 5s..I just got this mount off ebay.

View attachment 212496

View attachment 212497

View attachment 212498

- Messages

- 6,754

- Reaction score

- 12,426

- Location

- ST.LOUIS

- Arrma RC's

- BigRock 4x4

- Mojave

- Notorious

- Senton 6s

- Senton 3s

- Typhon 6s

It's a V1 mount with the fixed,non adjustable holes in mount..I like them cause pinion can't move..I've hammered this one flat couple times.lolThat mount looks thicker then the hot racing and old stock mount. Got a set of calipers? I’m curious…

Here's v1 an v2..they look the same thicknesses

Attachments

Last edited:

Velodromed

Snatching defeat from the jaws of victory!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 7,758

- Reaction score

- 13,925

- Location

- San Antonio, TX

- Arrma RC's

- BigRock 4x4

- Granite

- Kraton 6s

- Kraton 4s

- Notorious

- Outcast 4s

- Vorteks

- Voltage

- Infraction 4x4

Ok, it was the picture then. The new mounts are a good millimeter thicker maybe a touch more. I have one in old yeller and have yet to bend it so it’s pretty solid.It's a V1 mount with the fixed,non adjustable holes in mount..I like them cause pinion can't move..I've hammered this one flat couple times.lol

Here's v1 an v2..they look the same thicknesses

Last edited:

- Thread starter

- #9

Thank you all so much .. I have bashed it out a bit ! I may need a little shim under one side ..

I will also get some washers also tomorrow.

Fingers crossed this will do it .. I am surprised that I have managed to bend the mount

Thank you again !

I will also get some washers also tomorrow.

Fingers crossed this will do it .. I am surprised that I have managed to bend the mount

Thank you again !

- Messages

- 6,754

- Reaction score

- 12,426

- Location

- ST.LOUIS

- Arrma RC's

- BigRock 4x4

- Mojave

- Notorious

- Senton 6s

- Senton 3s

- Typhon 6s

Stick something under back of motor for support..packing foam works,furniture leg pads,,,it'll helpThank you all so much .. I have bashed it out a bit ! I may need a little shim under one side ..

I will also get some washers also tomorrow.

Fingers crossed this will do it .. I am surprised that I have managed to bend the mount

Thank you again !

Hector_Fisher

Very Active Member

I'm starting to think that the 3s motor plate bending is NOT from hard landings when landing on 4 wheels.Stick something under back of motor for support..packing foam works,furniture leg pads,,,it'll help

The types of failure I'm seeing don't indicate any twisting of the motor mount (either side to side or up and down impacts). For example, if the motor plate warped when landing on 4 wheels from a high jump, the top part of the motor plate would be pulled out from the power module (forward) and the bottom would be pulled into the power module (rear). Most of the pictures of bent mounts I've seen, including from my own experience, are that the top and bottom side of the mount are bent equally, like the first picture OP posted. Things just don't add up.

This leads me to believe that the common bent 3s motor mounts are from hard frontal impacts. This would pull the motor forward. Since the motor plate is captured on the right and left sides, this causes it to bend at the weakest point, the adjustable slots. Physics wise, that would make the motor plate looke like a bridge, suspended between the two outside screws on the power module with the motor as the weight on the bridge. The failure being "sag" from excessive force on the middle of the bridge when the motor is pulled forward.

It makes me curious... I know there are lots of solutions people have found for preventing side to side movement of the motor: O-rings, DIY cradles for the motor. But i haven't seen much DIY stuff that would help with forward motion of the motor. M2C's motor plate/brace is the right idea i think -- they have a fatty brace that holds up the middle of the motor plate, making the bridge shorter and harder to bend. Just $$$$$.

I'm pretty confident that motor plate failure comes from a design flaw that can't withstand hard frontal impacts (but can reasonably handle all other types of impacts). Curious what others think about this, and what DIY solutions would prevent that kind of failure.

Kla912000

Very Active Member

I think I agree with you. Maybe that's why I have never bent a motor mount yet. I have never sent my truck into a wall at 50mph. Lol !!!I'm starting to think that the 3s motor plate bending is NOT from hard landings when landing on 4 wheels.

The types of failure I'm seeing don't indicate any twisting of the motor mount (either side to side or up and down impacts). For example, if the motor plate warped when landing on 4 wheels from a high jump, the top part of the motor plate would be pulled out from the power module (forward) and the bottom would be pulled into the power module (rear). Most of the pictures of bent mounts I've seen, including from my own experience, are that the top and bottom side of the mount are bent equally, like the first picture OP posted. Things just don't add up.

This leads me to believe that the common bent 3s motor mounts are from hard frontal impacts. This would pull the motor forward. Since the motor plate is captured on the right and left sides, this causes it to bend at the weakest point, the adjustable slots. Physics wise, that would make the motor plate looke like a bridge, suspended between the two outside screws on the power module with the motor as the weight on the bridge. The failure being "sag" from excessive force on the middle of the bridge when the motor is pulled forward.

It makes me curious... I know there are lots of solutions people have found for preventing side to side movement of the motor: O-rings, DIY cradles for the motor. But i haven't seen much DIY stuff that would help with forward motion of the motor. M2C's motor plate/brace is the right idea i think -- they have a fatty brace that holds up the middle of the motor plate, making the bridge shorter and harder to bend. Just $$$$$.

I'm pretty confident that motor plate failure comes from a design flaw that can't withstand hard frontal impacts (but can reasonably handle all other types of impacts). Curious what others think about this, and what DIY solutions would prevent that kind of failure.

- Thread starter

- #13

There is still timeI think I agree with you. Maybe that's why I have never bent a motor mount yet. I have never sent my truck into a wall at 50mph. Lol !!!

Hector_Fisher

Very Active Member

Not walls. All it takes is one big jump... When you're truck is 30 ft in the air and you're desperately pinning the throttle to get it to nose up, and you watch in horror as it careens downward, almost as if in slow motion, face first into the concrete..... game overI think I agree with you. Maybe that's why I have never bent a motor mount yet. I have never sent my truck into a wall at 50mph. Lol !!!

Kla912000

Very Active Member

Never lawn darted my trucks either.Not walls. All it takes is one big jump... When you're truck is 30 ft in the air and you're desperately pinning the throttle to get it to nose up, and you watch in horror as it careens downward, almost as if in slow motion, face first into the concrete..... game overthe "WASTED" is already popping up above your RC.

Similar threads

- Replies

- 8

- Views

- 619