Velodromed

Snatching defeat from the jaws of victory!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 7,758

- Reaction score

- 13,925

- Location

- San Antonio, TX

- Arrma RC's

- BigRock 4x4

- Granite

- Kraton 6s

- Kraton 4s

- Notorious

- Outcast 4s

- Vorteks

- Voltage

- Infraction 4x4

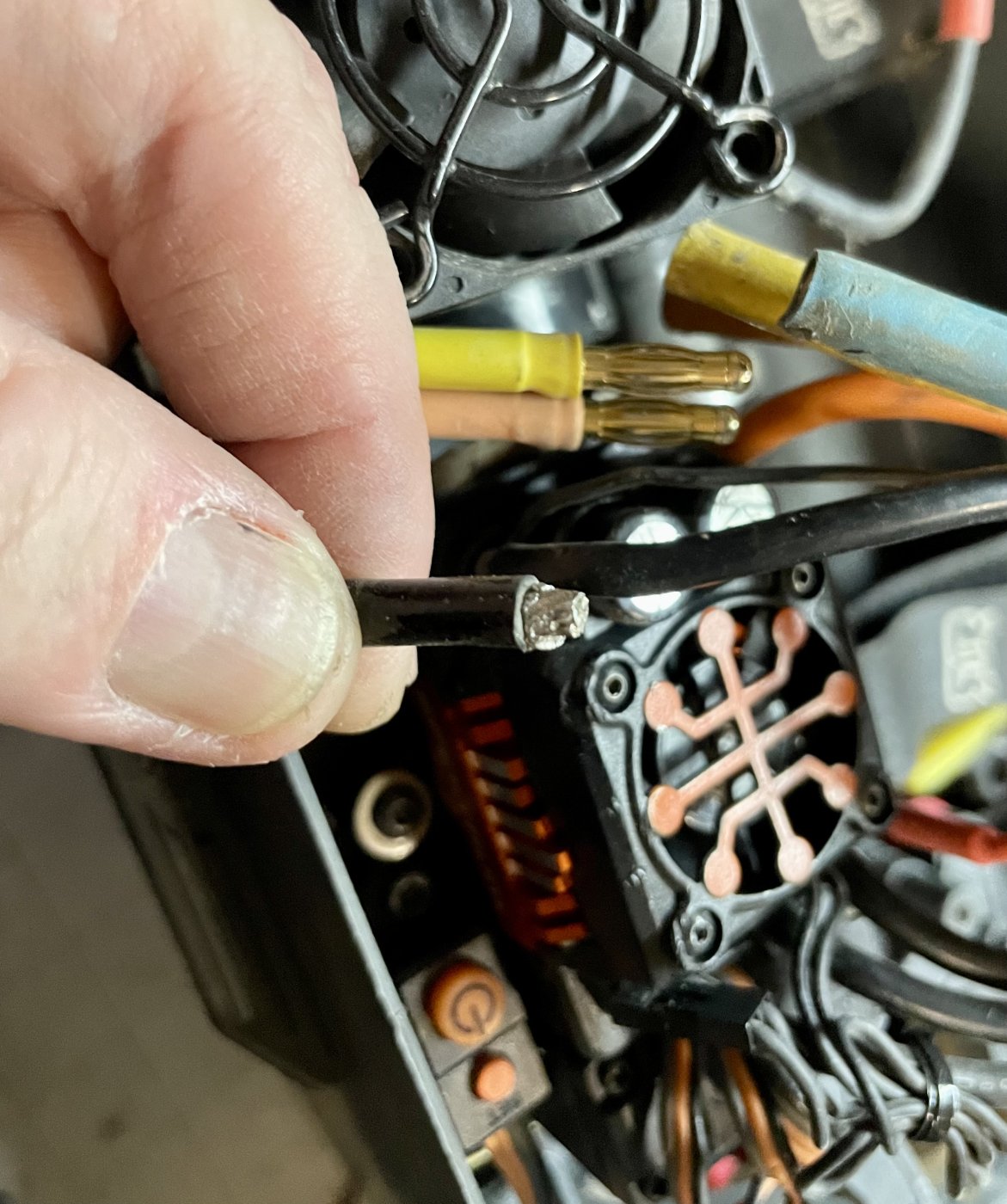

The motor is only a few months old., It’s a surpass 4068. Looks like the solder let loose and doesn’t look like it was a well done job. I’ve read that soldering motor wires is not easy, if the wires are the ‘stiff’ kind, as these seem to be. But since it looks like the solder just let loose, can I clean, tin and try?