jondilly1974

Speed running apprentice, motor Slayer 🤘

Lifetime Premium!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 26,134

- Reaction score

- 38,841

- Location

- Toledo, OH

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Kraton EXB

- Senton 3s

- Typhon 6s

- Typhon 3s

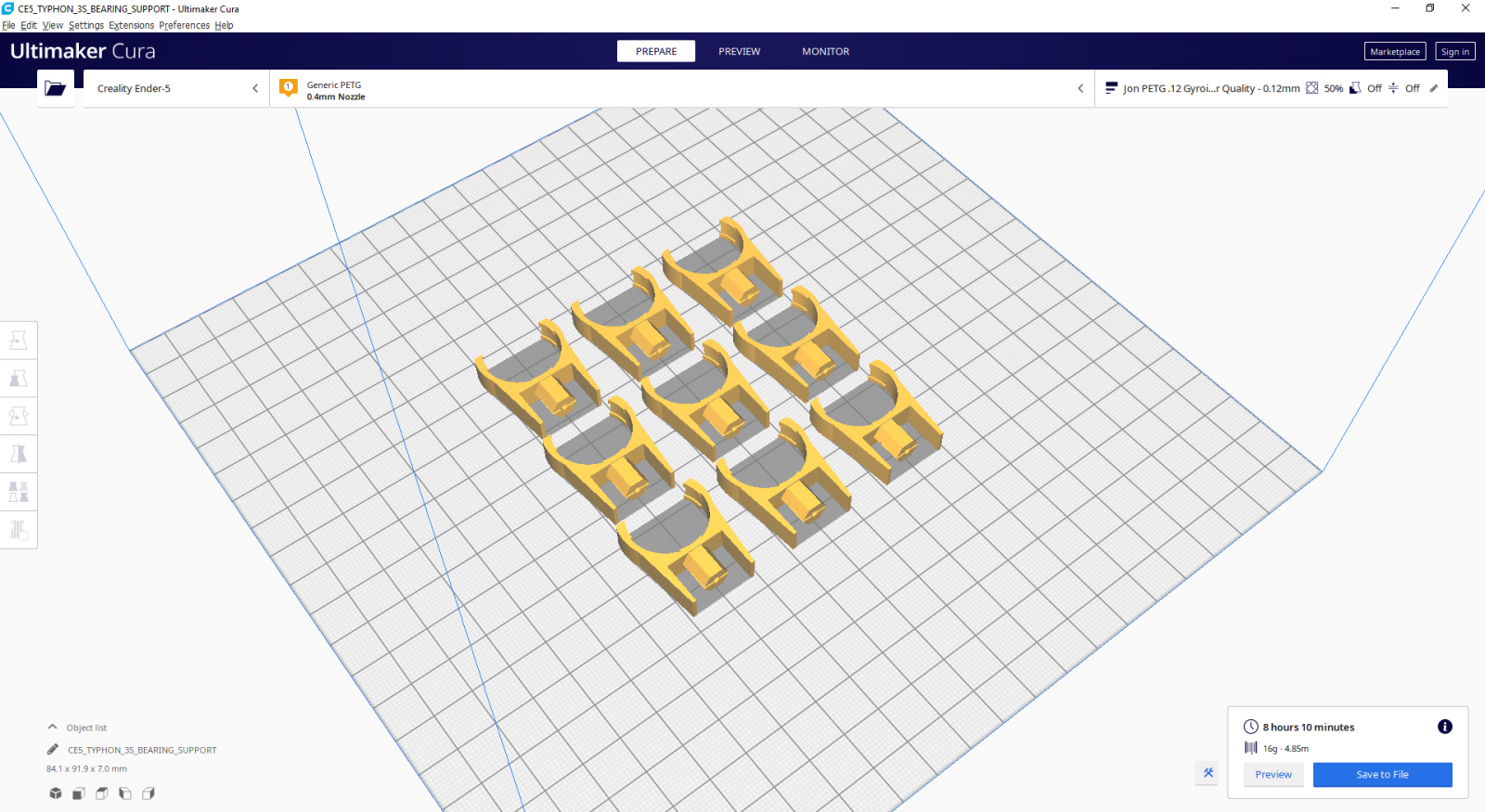

Just wanted to give a shout out to @Camaroboy383 for the hookup on these STL files for the Arrma 3S/4S center driveshaft bearing support. I can't seem to buy enough of these things. Now I can print as many as I need. ??