Mr.Vylan

If you're in control, you're not going fast enough

- Messages

- 998

- Reaction score

- 952

- Location

- Bay Area, California

- Arrma RC's

- Felony

- Kraton 6s

- Senton 6s

- Senton 3s

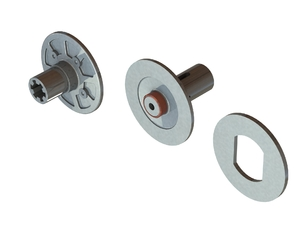

When I throttle the hub assembly turns (slow) as if under pressure.

QUESTIONS:

PART 1

I know, I know too many questions and variables. I simply want to avoid replacing parts since I'm not sure if it is the slipper clutch assembly or the motor.

Again, when the slipper clutch/gear is not attached the motor appears to be spinning fine.

Thanks in advance.

- My motor is spinning fast by itself but sounds a little rough.

- The slipper clutch appears to be functioning <-- newbie, so only assuming

QUESTIONS:

PART 1

- Is a motor either working or not?

IF NO, - If the motor has bad bearings or something internally wrong will it not be able to turn the driveshaft at normal speed?

- If the slipper clutch is bad, how can I test it?

- If the slipper clutch is binding (bad), will it prevent the motor from optimally turning?

I know, I know too many questions and variables. I simply want to avoid replacing parts since I'm not sure if it is the slipper clutch assembly or the motor.

Again, when the slipper clutch/gear is not attached the motor appears to be spinning fine.

Thanks in advance.