MrTitanium

Speak softly and carry a big stick.

- Messages

- 2,837

- Reaction score

- 14,901

- Arrma RC's

- BigRock

- BigRock 4x4

- Granite Grom

- Kraton EXB

- Nero

- Infraction 4x4

I bought a set of EXB chassis braces (ARA320568 120mm and ARA320565 118mm) to replace the plastic ARA320620 units. Although they bolt on nicely, the EXB units don’t have the protruded part that snaps into the chassis. So the stress is now transferred entirely onto the screws. I’m not fond of this idea.

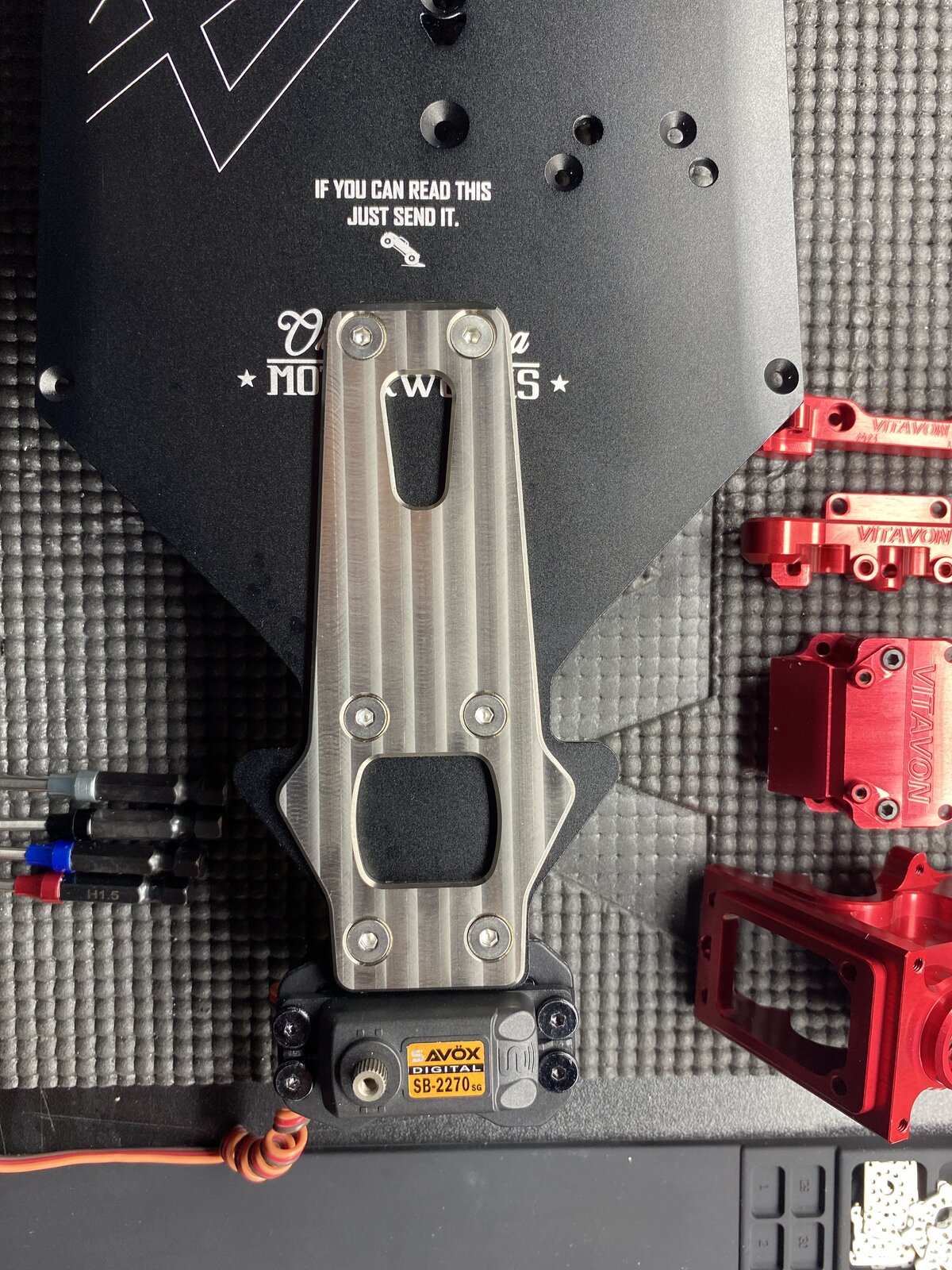

So I bought the Scotched RC titanium rear skid plate to help keep things tight. The problem is that the BR chassis does not have the two (forward) access holes needed to successfully install the brace to its full advantage.

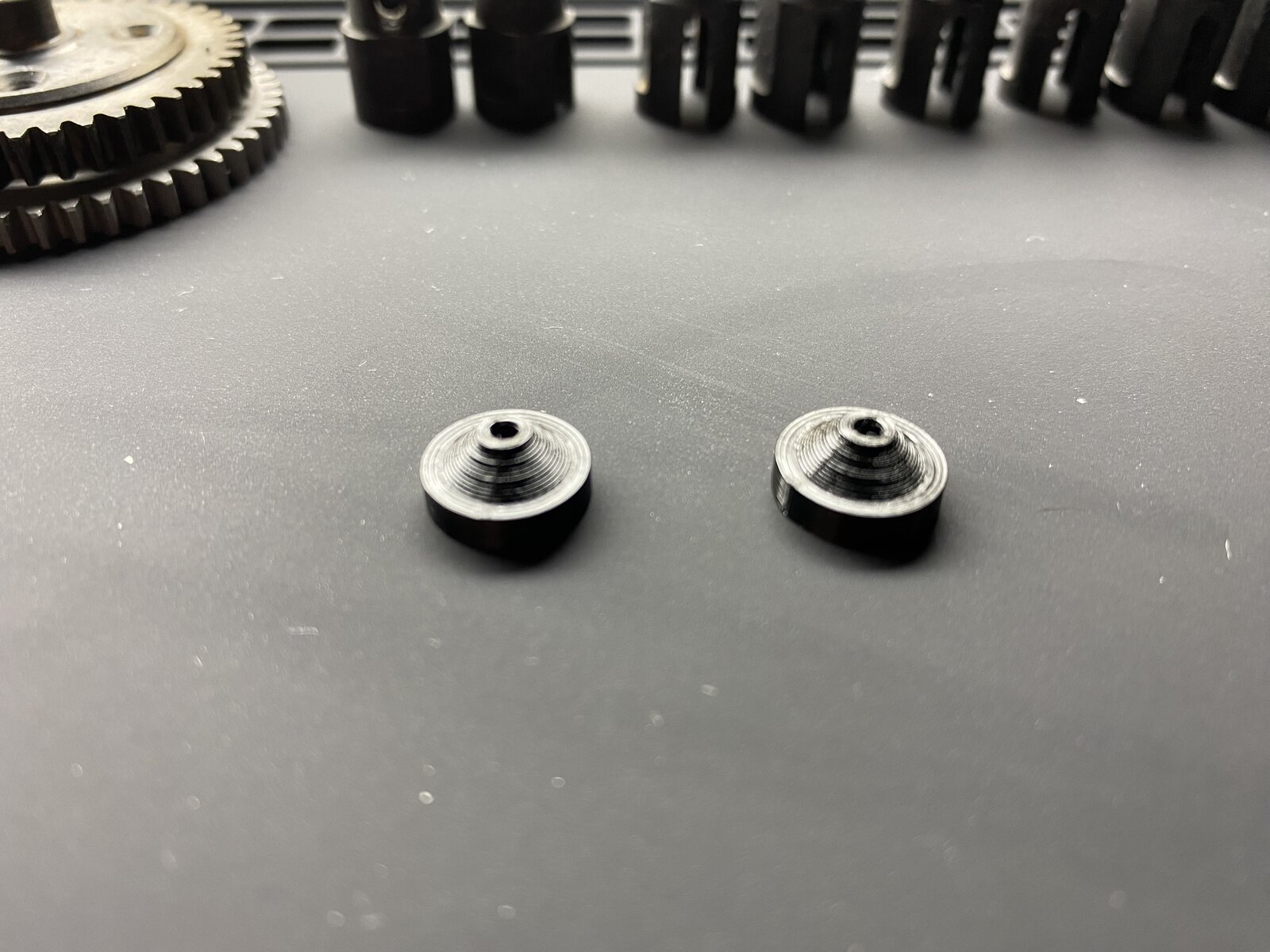

I printed out some bushings to help with drilling of the chassis. Some might say, “just scribe the hole and use an automatic centerpunch. Don’t over complicate things!”. True, but I’m all about quality and precision. I don't "eyeball" things.

Hopefully this helps out someone else looking to beef-up their BR6s chassis (stock ARA320732 or 7075-T6 ARA320610).

So I bought the Scotched RC titanium rear skid plate to help keep things tight. The problem is that the BR chassis does not have the two (forward) access holes needed to successfully install the brace to its full advantage.

I printed out some bushings to help with drilling of the chassis. Some might say, “just scribe the hole and use an automatic centerpunch. Don’t over complicate things!”. True, but I’m all about quality and precision. I don't "eyeball" things.

Hopefully this helps out someone else looking to beef-up their BR6s chassis (stock ARA320732 or 7075-T6 ARA320610).

Last edited: