amateurhour

Active Member

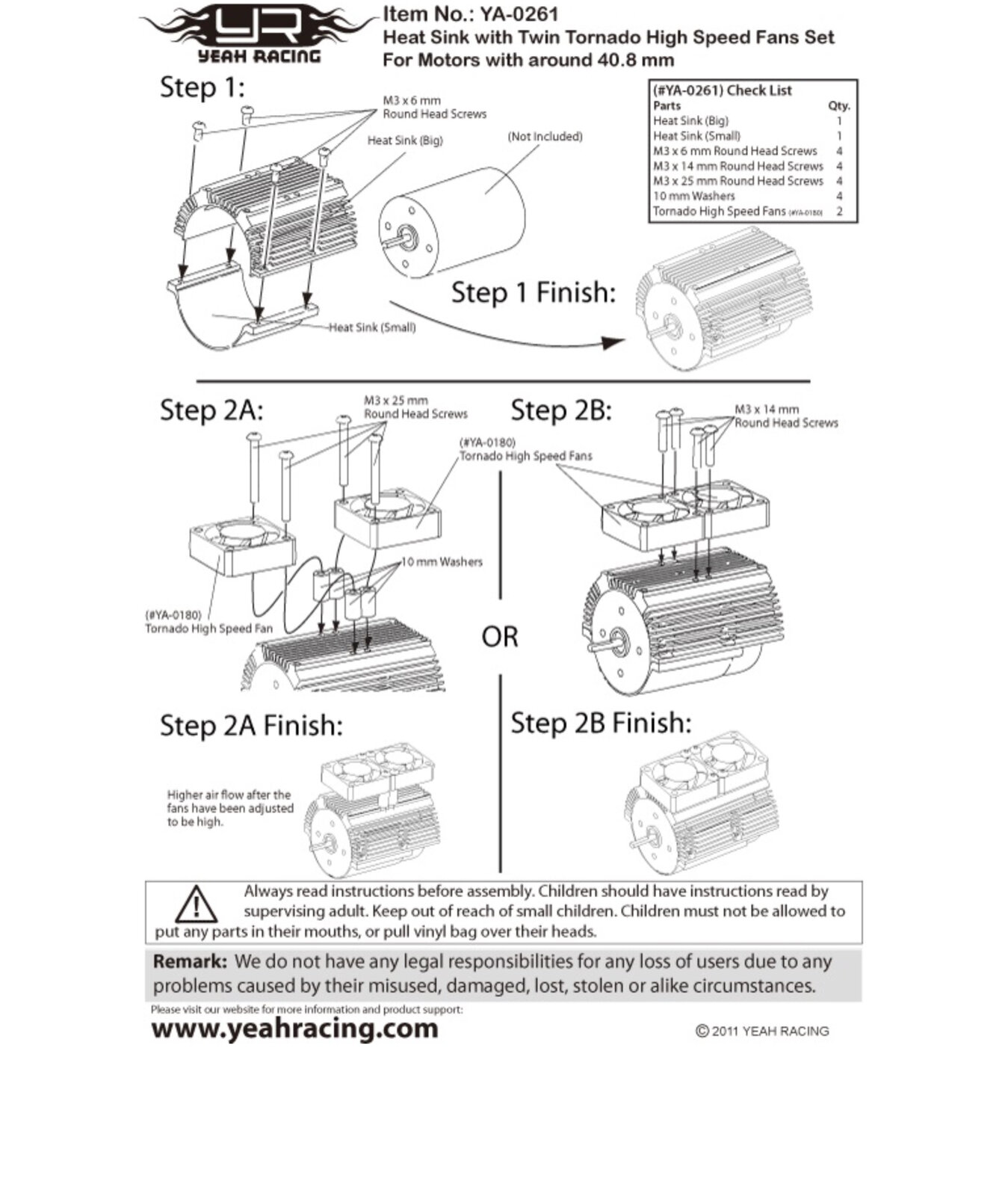

In the yeah racing instructions it shows the spacers for holding the fans off of the heatsink.

They also only included four mounting screws, so eight spacers wouldn’t be much help. In racing most fans are held on with just two mounting holes. Racers don’t tend to send it or crash as much as bashers. For bashing you should use all four mounting holes.

They also only included four mounting screws, so eight spacers wouldn’t be much help. In racing most fans are held on with just two mounting holes. Racers don’t tend to send it or crash as much as bashers. For bashing you should use all four mounting holes.

Last edited: