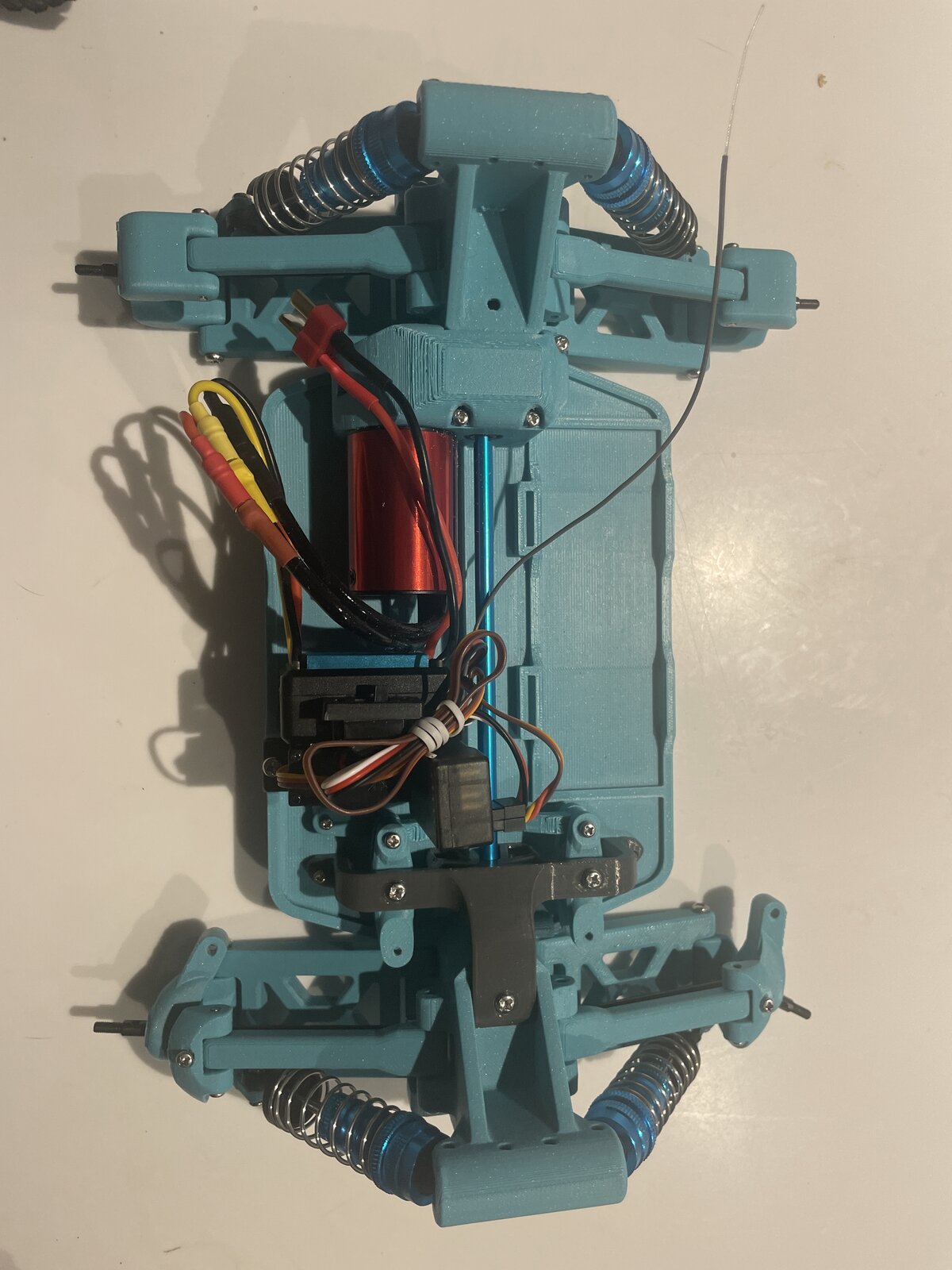

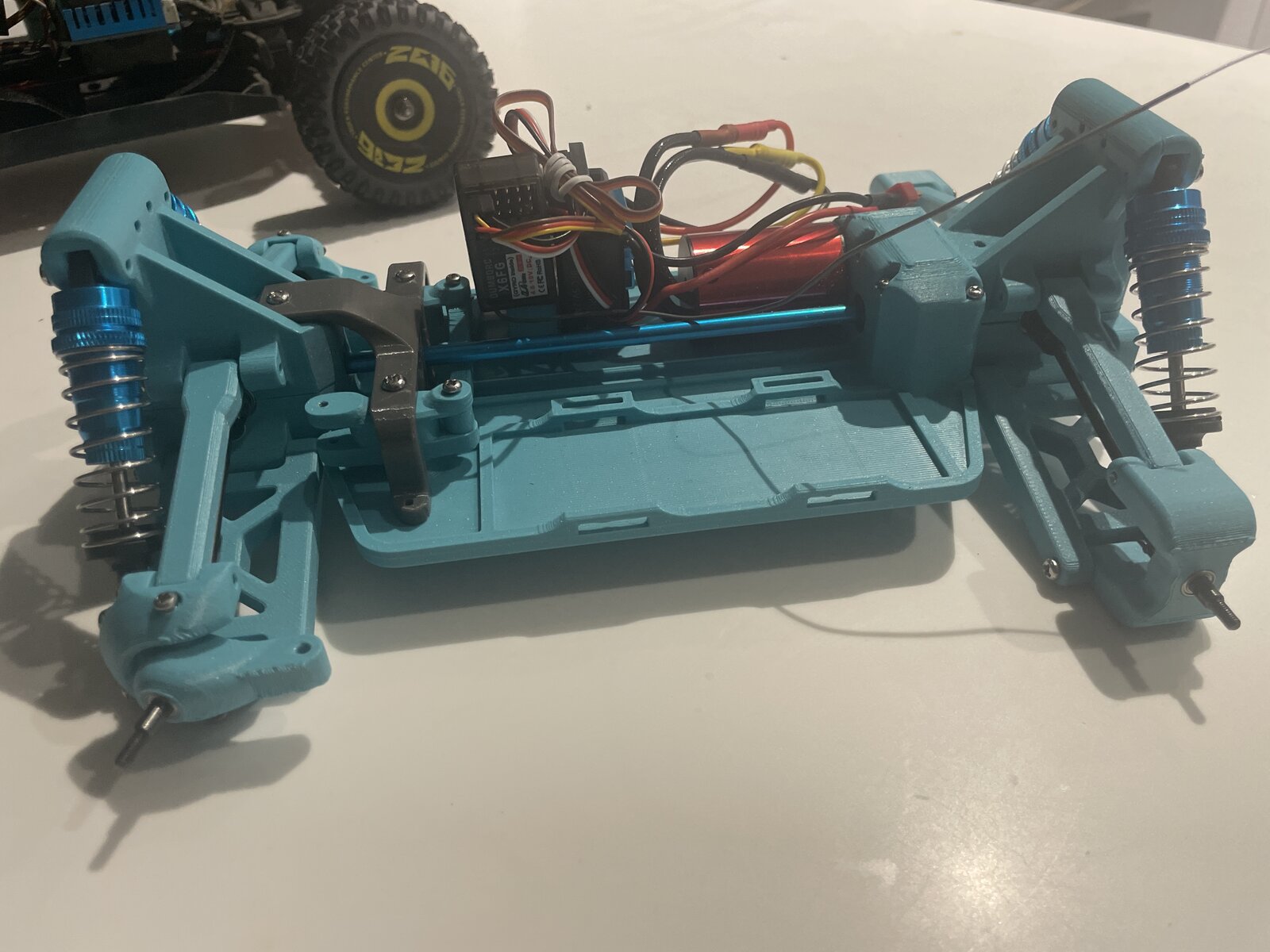

I designed a chassis around the wltoys 144001 drivetrain using Solidworks for a college class. So far it’s been a fun budget build that really scratches the itch. I plan to make this a kit on 3d cults and Bambu Studio for the ultimate DIYers.

This is version 2.0.

The first version was an 1/8th scale with senton 3s blx electronics. This failed immediately because I used petg. Which has a mediocre impact resistance. In other words it’s brittle. This one is made using ABS and I have yet to see its durability. I plan to use nylon once the design is finished in hopes of strength similar to Arrma plastic. Im sure you know what they mean by Arrma Tough. Until someone makes a 400mm ^3 high temp printer that doesn’t cost a 4 grand, I’ll stick to this smaller 1/14 scale platform.

Anyone know if horizon hobby looking for CAD designers?

This is version 2.0.

The first version was an 1/8th scale with senton 3s blx electronics. This failed immediately because I used petg. Which has a mediocre impact resistance. In other words it’s brittle. This one is made using ABS and I have yet to see its durability. I plan to use nylon once the design is finished in hopes of strength similar to Arrma plastic. Im sure you know what they mean by Arrma Tough. Until someone makes a 400mm ^3 high temp printer that doesn’t cost a 4 grand, I’ll stick to this smaller 1/14 scale platform.

Anyone know if horizon hobby looking for CAD designers?