Please before I start I am well beyond using a giant flat bladed screwdriver each side to wiggle it out.

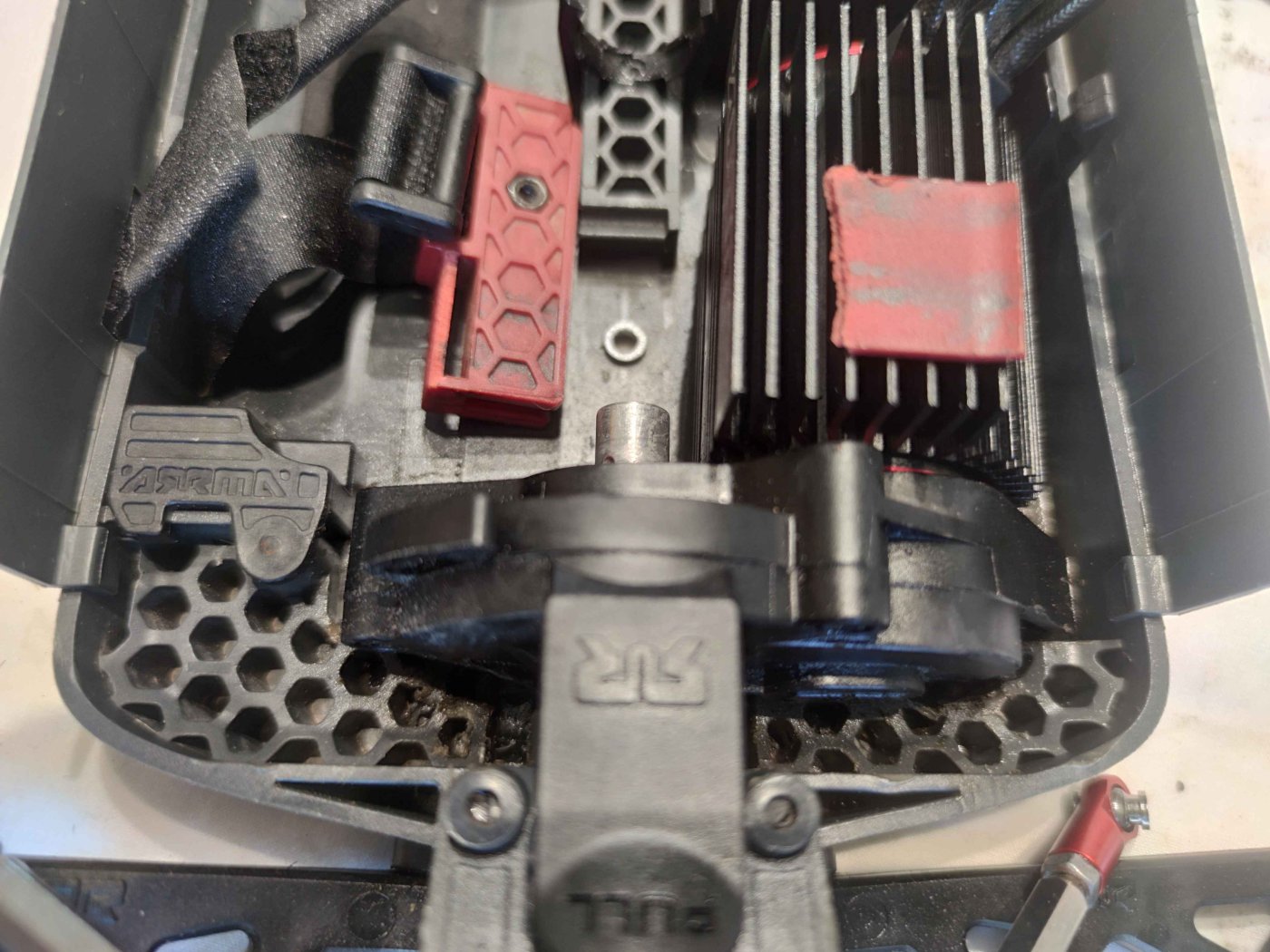

My power module is seized onto the shaft/spline that leads to the rear diff. It is not dirt under the power module!

The car was luckily running on 2s at full speed down my street when somehow it caught on the ground and went from 30 -40mph to 0mph instantly. It was travelling over some block paving although it was all smoothly laid but it did catch.

This caused the esc to bit broken away from its mountings, the battery to become unplugged, the red piece of plastic that sticks up to guard the driveshaft was just lying inside the car so the power module must have shifted to break that off, and the power module is very hard to turn like the mesh is really tight. (diffs spin fine)

I have watched every video, read loads of posts and am at my wits end, I have been levering at it for a week. My honeycomb is getting mashed.

The power module is moving freely, I know this because eventually I removed the top diff cover to try and get it out but it did not help. However it did give me plenty slack to see that the power module moves freely on the rails and is not held in by dirt.

When levering the sides you can easily see that the power module moves freely but the shaft is stuck.

When levering with the top diff cover removed it was trying to pull the diff out from where it was sitting....the shaft is seized.

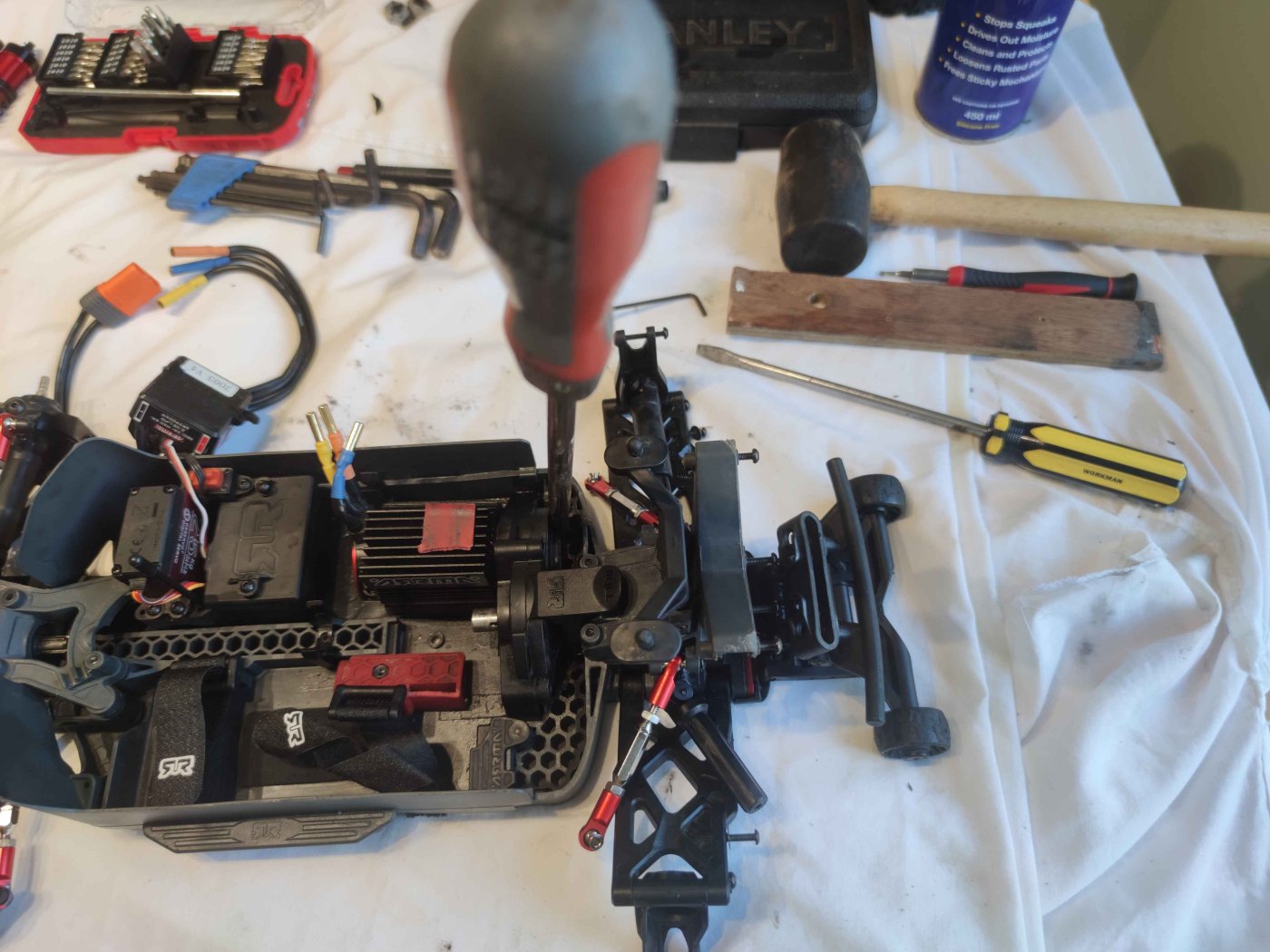

I have been drowning it in WD40, for a week, removed top cover as I mentioned, I have resorted to hitting it with a giant rubber mallet and a piece of wood with tons of force to try and break it free.....it is seized, I know it seems unlikely, it is seized on there.....please I am out of ideas.

It is a v2 granite in great condition that has not really been bashed, this accident was the hardest thing it has ever endured. Help.

Stupid design, how can i have a RC that I cannot take apart???

Oh and yes i know about the tab you have to pull and slide a credit card under it so I do not have to keep tugging at that, this of course wasnt a issue when i removed the diff housing.

I have levered it so hard that the back of the chassis is flexing massively. It honestly looks like not only will I have to replace slipper clutch/gear and the motor but at this rate likely also the chassis which is going to be destroyed as well as power module housing which is just silly.

Lastly I have no idea if this issue was caused by the accident or it was just stuck anyway, until I can get it off so I can see what the hell is going on.

My power module is seized onto the shaft/spline that leads to the rear diff. It is not dirt under the power module!

The car was luckily running on 2s at full speed down my street when somehow it caught on the ground and went from 30 -40mph to 0mph instantly. It was travelling over some block paving although it was all smoothly laid but it did catch.

This caused the esc to bit broken away from its mountings, the battery to become unplugged, the red piece of plastic that sticks up to guard the driveshaft was just lying inside the car so the power module must have shifted to break that off, and the power module is very hard to turn like the mesh is really tight. (diffs spin fine)

I have watched every video, read loads of posts and am at my wits end, I have been levering at it for a week. My honeycomb is getting mashed.

The power module is moving freely, I know this because eventually I removed the top diff cover to try and get it out but it did not help. However it did give me plenty slack to see that the power module moves freely on the rails and is not held in by dirt.

When levering the sides you can easily see that the power module moves freely but the shaft is stuck.

When levering with the top diff cover removed it was trying to pull the diff out from where it was sitting....the shaft is seized.

I have been drowning it in WD40, for a week, removed top cover as I mentioned, I have resorted to hitting it with a giant rubber mallet and a piece of wood with tons of force to try and break it free.....it is seized, I know it seems unlikely, it is seized on there.....please I am out of ideas.

It is a v2 granite in great condition that has not really been bashed, this accident was the hardest thing it has ever endured. Help.

Stupid design, how can i have a RC that I cannot take apart???

Oh and yes i know about the tab you have to pull and slide a credit card under it so I do not have to keep tugging at that, this of course wasnt a issue when i removed the diff housing.

I have levered it so hard that the back of the chassis is flexing massively. It honestly looks like not only will I have to replace slipper clutch/gear and the motor but at this rate likely also the chassis which is going to be destroyed as well as power module housing which is just silly.

Lastly I have no idea if this issue was caused by the accident or it was just stuck anyway, until I can get it off so I can see what the hell is going on.

Last edited: